Weight and number of gas silicate blocks in the pallet

When planning the construction of a house, a bathhouse, a summer residence or any outbuilding, you should decide on building materials, as well as make a lot of calculations. At the present time, gas silicate blocks, which are widely used in the construction of one- and two-story houses, are especially popular and trusted among builders.

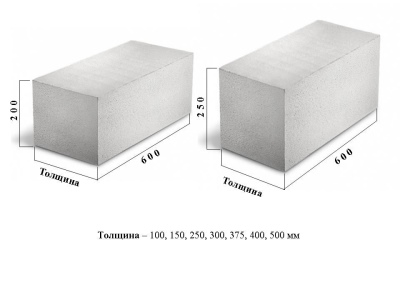

A gas silicate block is a stone of artificial origin, endowed with a cellular structure, made of cement, quartz sand, water, lime, aluminum powder and strengthening additives. There are two types of blocks on the market - trough and wall, which, in turn, are produced in different sizes - 250x100x600, 250x400x600, 250x200x600, 250x300x600 and 600x300x200 mm.

The standard and widely used block is 20x30x60 cm. This building material is made by several methods - with and without an autoclave. To start construction without spending extra money, you need to very carefully calculate the amount of materials.

Number of pieces of gas silicate

Having the project in hand and knowing the area of the future object, it is not at all difficult to carry out the corresponding calculations of the amount of materials required for construction. Gas silicate blocks are sold and delivered on special wooden pallets, which greatly facilitates the process of loading, unloading and transportation.

To determine the exact amount, you need to know how much gas silicate fits in the pan. The number of blocks depends on their size:

- 120 pieces fit on a pallet if you buy blocks of 600x100x250 mm;

- 40 pieces are placed on a pallet if you purchase blocks of 250x300x600 mm;

- 50 pieces capacity when it comes to blocks 600x300x200 mm;

- 56 pieces are stacked on a pallet if the block has a size of 600x200x250 mm;

- 32 units on a wooden pallet, if a block of 600x400x250 mm is required.

In addition to standard sizes, builders often use materials with individual dimensions. - 600x150x250 mm, of which 80 units are placed on a pallet, 600x250x250 mm (capacity 48 pieces), blocks for partitions 600x200x120 mm (180 units fit), wall types with dimensions 75x200x600 mm (180 pieces on a pallet), as well as models 600x400x200 mm (for pallet 40 pieces).

When purchasing gas silicate blocks, the buyer is faced with the fact that the cost is indicated in m3, so you need to navigate in the number of cubes on a pallet.

How many cubes are in a pallet?

The capacity of one pallet in m3 can be easily calculated by knowing the size of the gas silicate block. For those who are not strong in mathematical calculations or are afraid to make inaccuracies, below is a simple table showing the amount of building material placed in cubes on one pallet:

- blocks 60x40x20 cm - 1.92 m3;

- block 60x30x20 cm - 1.8 m3;

- material with dimensions 60x25x25 cm - 1.8 m3;

- gas silicate 60x20x25 cm - 1.68 m3;

- gas silicate material 60x40x25cm - 1.92 m3;

- blocks 60x30x25 cm - 1.8 m3;

- gas silicates 60x15x25 cm - 1.8 m3;

- block 60x10x25 cm - 1.8 m3.

There is also data for materials with non-standard dimensions - wall blocks 60x20x7.5 cm - 1.62 m3, for partitions 60x20x12 cm - 1.7 m3, for load-bearing walls 50x20x60 cm - 2.4 m3. In addition to the quantity, it is also necessary to know the mass of the building material.

How to determine weight?

Gas silicate blocks are one of the lightest, strongest building materials, only wood is lighter. That is why you do not have to worry about the loads on the foundation, even when building a two-story house. The weight of gas silicate consists of several indicators - size and density, therefore the higher the density, the greater the mass of the material. On average, the mass of one unit ranges from 7 to 43 kg.

For ease of calculation, below are data on the weight of gas silicates.

- A block with a density of D400 and a size of 60x10x25 cm is endowed with a mass of 7.2 kg. The specific gravity of one m3 is 480 kg.

- A block with a density of D400 and dimensions of 60x20x25 cm has a weight of 14.4 kg. The weight of one cube is 480 kg.

- Gas silicate 60x30x25 cm (density grade D400) weighs 21.6 kg. 1 cubic meter of such building material is 480 kg / m3.

- Material with a D400 density mark and a size of 60x40x25 cm is endowed with a mass of 28.8 kg, while 1 cube will be 480 kg.

- A block of 60x10x25 cm with a density of D500 has a weight of 8.7 kg, and 1 m3 - 580 kg.

- A gas silicate block of the D500 brand and with dimensions of 60x20x25 cm weighs 17.4 kg. The specific gravity of the cube is 580 kg.

- Building material of the D500 brand with a size of 60x30x25 cm is quite heavy - 26.1 kg, and one m3 is equal to 580 kg.

- Blocks with a density of D500 and dimensions of 60x40x25 cm have a mass of 34.8 kg, while one cube reaches 580 kg.

- Gas silicate 60x10x25 cm (density D600) is characterized by a mass of 10.8 kg. 1 m3 of such material will be 720 kg.

- A block 60x20x25 cm (density D600) is endowed with a weight of 21.6 kg, and a cube of this material will be 720 kg.

- Building material brand D600 and parameters 60x30x25 cm has a weight of 32.4 kg, while the specific gravity of one cube reaches 720 kg.

- Gas silicate 60x40x25 cm (density D600) weighs 43.2 kg, and a cube of such material reaches 720 kg.

It is important to remember that over time (after the end of construction) the mass of gas blocks increases, while the strength indicators become higher. Understanding the approximate volume of upcoming construction work, you can easily determine the required number of pallets with material.

How to calculate the number of pallets?

There are several ways to determine the number of pallets with gas blocks - find a special calculator on a specialized website and use it, contact a construction company specialist, an online store manager, or calculate it yourself.

To calculate, you need to know exactly the height, length, width and thickness of the walls, the area of window and door openings, and determine the brand, type and size of blocks. With all the data available, the amount of material is easily calculated, and using the information (table) on the capacity in one pallet, it is easy to determine their exact number. In addition, you can use special calculation formulas (one by one):

- S = PH, where S is the total area of the wall, H is the height of the wall, P is the perimeter;

- area of door and window openings S pr. = WHN (windows) + WHN (doors), where W is the width, H is the height, N is the number;

- area of walls without openings S = S total. - S pr.

When calculating, there may be a small error, not exceeding 2-5%, since the material is quite large.

The comment was sent successfully.