Choosing silicate tongue-and-groove plates

The purchase of silicate tongue-and-groove plates is very important nowadays. You can successfully use partition blocks 498x70x250 mm and other GWPs, but this must be done very deliberately and carefully. Along with the general rules for the selection and sound insulation of tongue-and-groove partitions, it is necessary to take into account the installation features.

Peculiarities

Silicate tongue-and-groove plates are a high-quality and inexpensive finishing solution. Almost any design can be assembled from them. The assembly is carried out practically according to the same principles as in the well-known Lego constructor. You can visually confuse silicate blocks with gypsum counterparts. But their production technology is fundamentally different. Silicate-based products are more widely used than gypsum products, and the efficiency will be higher.

This building material has a fairly high density. This increases the strength of the structure, but also makes it heavier. Therefore, the area of the product is more than 2 times less than that of a plaster structure.

However, an increased complexity of processing is noted, which makes it difficult to perform the masonry. The thermal protection of a silicate board is worse than that of gypsum boards; sound insulation is also weaker.

However, this drawback (associated with low porosity) cannot be considered as some serious obstacle to normal use, because such products are used only indoors. Positive characteristics of silicate-based blocks:

- excellent load-bearing capacity (due to high density);

- few pores to reduce moisture penetration;

- cheapness (about 50% more affordable than analogues);

- significant production volumes at all specialized enterprises;

- high dimensional accuracy;

- the possibility of laying both on a rough floor and on floors;

- no need for additional plastering.

Silicate tongue-and-groove slabs are usually used to quickly and soundly erect load-bearing walls inside the house. But their massive use is impractical. This provokes an excessive load on the base of the building and makes it more complicated and more expensive. But as a material for an interior partition, a silicate block is ideal in all respects.

It can be used immediately after the completion of the frame work, but before finishing manipulations and the formation of a finished floor.

What are they?

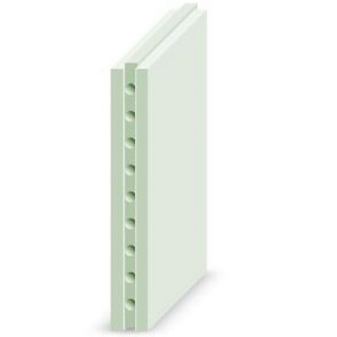

A typical partition plate is rectangular in shape. It has a locking tongue-and-groove, which gave the name to the entire product. The standard version is designed for dry or low-humidity rooms. It is also used as a cladding of load-bearing elements of a building. The key differences between the baffles concern primarily the filling level and moisture resistance.

The solid block has a relatively high strength. It is heavy and has a high bearing capacity. Such a product is suitable for a partition, inside which a door is placed. The hollow type, thanks to the through longitudinal channels, improves protection from frost and from extraneous noise.

A simple stove for a dry room absorbs from 25 to 32% of water, and a moisture resistant (due to special additives) has a water absorption of no more than 5%.

Wall privates PGP, according to official standards, most often have the size:

- 66.7x50;

- 90x30;

- 80x40;

- 60x30 cm.

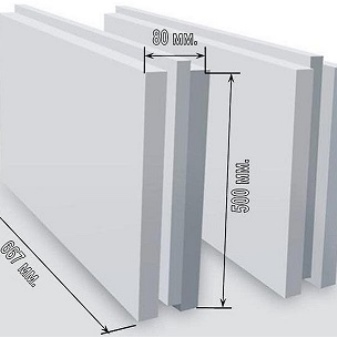

The thickness is most often 8 or 10 cm. Density is at least 1870 kg per 1 m3. The thermal conductivity coefficient is normally 0.29 or 0.35.The large-format wall block 498x70x250 is popular. Usually, cement M-150 is used for its manufacture, and 80 pieces of blocks are laid out on a pallet.

Good results can also be obtained from the use of products 498x80x249 mm. Such products are supplied, for example, by the Yaroslavl Specialized Plant. The product is produced by pressing a wet sand-lime mixture. There is no need to use additives, but further curing with steam is required. Plates 498x115x250 mm are produced in a similar way.

Selection Tips

Some suppliers sell small-sized tongue-and-groove blocks. They are lighter than full-size ones, which makes it easier to work with. However, the problem is that the groove / ridge may be missing on horizontal surfaces. It is imperative to also take into account the level of thermal conductivity. Regardless of the manufacturer's promises, an additional noise-absorbing layer is required. For baths and other humid rooms, it is recommended to purchase a solid slab with increased resistance to moisture, that is, any silicate modification. If possible, you should choose lighter versions (each manufacturer offers its own versions with different weights). It is required to carefully check the certificate. Finally, you should definitely read the reviews.

Good products are supplied by:

- Knauf;

- "Magma";

- EKO (Yaroslavl);

- KZSM.

Installation rules

The most important requirement in preparing for the installation of the tongue-and-groove plate is a perfectly leveled platform. Even small slopes are unacceptable, because because of them, the structure may crack. Sound insulation can be increased by laying down a damping tape based on polyethylene foam at the very bottom. The same tape is placed in the gaps separating the slab from the main part of the building. Panels, like bricks, are laid with a bandage. It is absolutely impossible to combine vertical seams! Hand sawing is practiced only for small amounts of work. More large-scale construction already requires mechanization. The saw cut provokes the release of a mass of dust. Therefore, such work is more correct to perform on the street.

It is possible to connect the silicate plate with the capital part of the building using self-tapping screws and metal corners. The connection with steel plates helps to increase the rigidity. They are placed every 2 panels. The mounting points of the door blocks cannot be covered with lintels - the exception is openings more than 90 cm wide. A gap of about 2-3 cm remains from the partition to the overlap; you can close it with masonry mortar or polyurethane foam.

In the next video, you will see the laying of walls made of silicate tongue-and-groove slabs.

The comment was sent successfully.