Review of modern materials for finishing the facade of a private house

Cladding materials for the facade of the building play a protective and decorative role. They make it possible to make the building not only attractive and respectable, but also to improve its operational characteristics. Let's take a look at the advantages and disadvantages, as well as features of the most popular materials for outdoor decoration.

Requirements and norms

Today on the construction market there are many facade materials that differ in composition, properties, and appearance.

In this regard, it is important to decide what kind of material is suitable for a particular structure.

When choosing a material, you should consider the following criteria for its assessment:

- strength, reliability (the facade of the house is subject to heavy loads, including mechanical damage, so the coating must withstand them);

- moisture resistance (on how much the compositions for finishing the house are able to withstand moisture, its operational characteristics, appearance and durability depend);

- fire resistance (the ideal material for finishing is non-combustible, although this is quite rare, therefore it is important to at least exclude spontaneous combustion and the release of toxins during combustion);

- weather resistance (that is, resistance to environmental factors, primarily UV rays);

- windproof properties of the material (an important criterion when choosing hinged panels and slabs mounted on modern buildings; the effect is achieved by means of a special locking fastening);

- frost resistance (the ability of the coating to withstand freezing and defrosting cycles without losing the geometry of the material and performance);

- biostability (the ability to withstand the effects of pests, rodents, the absence of mold and mildew on the surface);

- environmental friendliness (one of the most important criteria for finishing materials when facing a country house or any room that involves people living or staying in it for a long time);

- long service life (a rare owner dreams of changing the cladding every 2-5 years, so modern facade materials are designed for 20-100 years of service);

- ease of maintenance (most of the hinged materials do not require constant maintenance and even have the ability to self-clean, others, for example, wood, imply regular impregnation with special compounds).

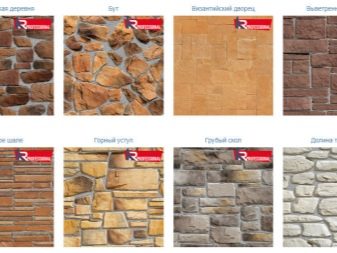

If we talk about aesthetic criteria, then this is, of course, an attractive appearance. Today's claddings and slabs are distinguished by a variety of designs and textures (a further review of examples of exteriors is a convincing confirmation of this). Separately, it is worth highlighting panels that imitate natural surfaces (stone, brick, wood, plaster). Modern technologies make it possible to produce them as close as possible in their color and texture to natural materials.

Sometimes, imitation cannot be determined even on closer inspection.

Exterior decoration

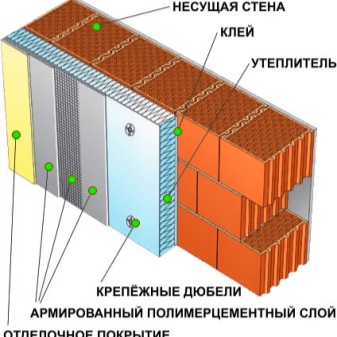

The material used for finishing determines the methods of its installation, and therefore the following cladding options are distinguished:

- wet (building mixtures are used);

- dry (finishing materials are fastened with bolts, dowels and other fasteners).

Depending on whether a small air space remains between the facade and the wall, the facades are distinguished:

- ventilated (assume a gap between the material and the wall or insulation, necessary for air circulation and the removal of excess moisture);

- non-ventilated (the material is attached directly to the wall).

The material for external processing, like the type of facade, is determined by the characteristics of the structure. For example, for a house made of foam blocks, the optimal facing materials will be brick, stone or facade tiles, in other words, hinged systems, composite material and traditional cladding.

For frame country houses, it is better to use sheet sheathing options. Galvanized profiled sheet will provide additional support for the structure, but it will not require additional strengthening of the foundation.

It is important to correctly combine insulation and cladding materials. The main rule is that one of the components must be non-flammable. So, for fiber cement non-combustible plates, you can use mineral wool insulation. It is not recommended to use them in combination with vinyl siding.

Wet and light plaster

Decorative plaster allows you to create an externally expensive, aesthetically attractive and original facade, which can be painted if desired. It is an environmentally friendly material that allows the walls to "breathe". Suitable for ventilated facades, however, the building needs high-quality internal sound and heat insulation, since plaster does not provide insulation and noise protection. All types of plasters tolerate temperature changes well, they are not afraid of moisture and direct sunlight.

The disadvantages of the material are the complexity of application, the need for careful preparation of the walls (leveling, preliminary antiseptic treatment, application of primers). If the installation technology is not followed, cracking and peeling of the plastered layer is possible.

There are the following types of plaster.

- Mineral. The type of plaster, which can be used for finishing walls the cheapest way, which makes it widespread.

Of the obvious features - absolute incombustibility, which allows you to combine the material with flammable insulation.

Suitable for all types of surfaces, but has low elasticity. This causes cracks to appear when the structure shrinks, which is why it is not suitable for newly built buildings. The average service life is 12-15 years.

- Acrylic. It is characterized by high elasticity, and therefore is suitable for decorating walls even in newly built buildings. Possessing higher indicators of strength and moisture resistance, it demonstrates a longer, up to 18 years, period of operation. The disadvantage of an acrylic mixture is its flammability, so it should not be used in combination with combustible insulation materials, for example, mineral wool. It is usually combined with foam insulation materials. In addition, the surface attracts dust, and it is unacceptable to wash it. You either have to regularly clean and care for the facade, or be prepared for the fact that it will quickly lose its visual appeal.

- Silicate. A material with excellent performance properties, including high elasticity, dust and dirt repellency, rain self-cleaning ability and long service life. The latter reaches 30 years old. Such characteristics are explained by the presence of potash glass in the composition. A feature of the material is its rapid solidification, therefore, it is necessary to apply plaster promptly, a team of specialists will be required. In addition, a special primer is required under it, which also increases the cost of installation work. The price for the mixture is also rather big.

- Silicone. The material, which has practically no drawbacks, like all types of plasters, the composition tolerates heat and frost, temperature "jumps", exposure to moisture and direct UV rays, is environmentally friendly and vapor permeable. Moreover, it is characterized by strength and increased wear resistance, non-flammable, combined with all types of surfaces and insulation. The disadvantage is the high cost, which, however, is offset by the increased technical characteristics of the mixture.

Suspended structures

Suspended structures involve the use of a lathing on which the finishing material is mounted. This method is gaining more and more popularity, since it allows you to create a ventilated facade, use insulation of the required thickness.

Thanks to the lathing, it is possible to hide irregularities and minor defects in the walls, and to carry out installation even at negative temperatures.

The lathing is usually made from timber or metal profiles. The latter option is preferable, since it does not require pretreatment of the elements of the sheathing with fire retardants and similar compositions for wood.

Siding is considered a type of hinged structures. It is a panel similar in size to the size of the boards. At the same time, the material has special grooves and locking systems, due to which it is assembled like a children's designer. This type of installation allows you to make it simple and efficient, it is possible to carry out installation work all year round. The material has improved performance properties, including hydro-wind protection.

The sizes and designs of the material are very diverse. It can be both colored models (bright glossy or quieter, neutral matte panels), and imitation of the texture of any natural material (brick, stone, wood). The material is easy to clean - most surfaces have a self-cleaning function. Wet cleaning of coatings is possible.

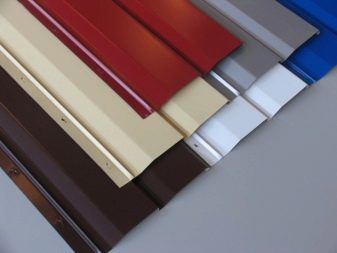

There are the following main types of siding panels.

- Plastic. It is based on PVC, as well as various modifiers and pigments. Such panels are strong enough, but with increased mechanical stress (shock) they can crack. The material is moisture resistant, withstands high and low temperatures, their abrupt change, and is resistant to UV protection.

Low weight (up to 5 kg / sq. M) does not require foundation reinforcement. The disadvantage is the low rate of fire safety.

- Metallic. Metal siding is based on aluminum or galvanized steel profiles. Metal siding is characterized by a large margin of safety compared to the PVC analogue. Features of the applied technologies, including special impregnation, provide anti-corrosion protection of the material, and with it durability. It also demonstrates high weather resistance, but is used only on reinforced substrates due to the increased weight of the material.

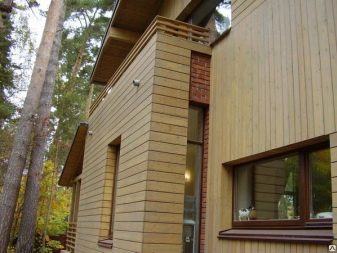

- Wooden. A wooden profile is a board or profile that has been dried and treated with antiseptics. The material is completely environmentally friendly, vapor permeable, has high thermal insulation performance, and is resistant to high temperatures.

Natural wood trim looks elegant and noble.

However, despite the processing of wooden panels with special compounds, their service life is short. During operation, siding requires regular maintenance.

- Fiber cement. The panels are made of cement mortar and dried cellulose, resulting in a durable, wear-resistant material with increased sound and thermal insulation characteristics. Among the advantages are impact resistance, weather resistance, preservation of the shade of the panels even under the influence of direct sunlight, thanks to ceramic spraying, high moisture resistance. The composition of the material determines its large weight (up to 25 kg / sq. M), which makes it possible to use it only on reinforced foundations.

Separately, it is necessary to highlight the basement siding, designed for cladding the lower part of the building. It has a greater thickness of profiles, better weather resistance and moisture resistance, resistance to mechanical damage. This is due to the fact that the basement of the house is more often than others exposed to shocks and other damage, freezing, moisture and other negative environmental factors.

Basement siding is rather rectangular panels. Their width is usually equal to the height of the basement and starts from 60 cm. This leads to ease of installation.

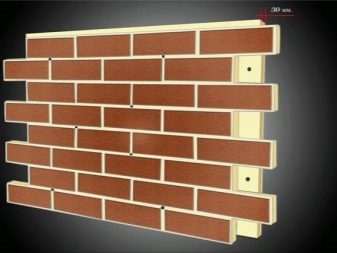

Facade panels have some similarities, in terms of fastening and possible materials used for manufacturing, with siding. They can be square or rectangular in various dimensions. Some slabs contain insulation. The multi-layer panels provide their high performance properties.

Another popular hinged type material is sandwich panels. They represent a "sandwich" in which the "middle" of the insulation is laid between 2 layers of rigid material (usually metal). The strength and durability of the structure is ensured by using the hot pressing method. The front side of the "sandwich" can be painted in any shade, be smooth or have a relief.

Sandwich panels are highly resistant to fire and moisture, exhibit excellent thermal insulation properties with low weight. The material is easy to install, and if a separate section is damaged, only it can be replaced without going through the entire facade.

Ventilated facades can also be created using facade cassettes.

If earlier they were used for cladding office buildings, now they are used to decorate private buildings as well. This is due to the durability and reliability of the material, its weather resistance. Externally, the cassettes are squares and rectangles of aluminum, steel, less often copper, covered with a protective polymer layer. The size and design of cassettes may vary.

Cladding materials: pros and cons

Each of the materials presented has specific advantages and disadvantages. Moreover, even within the same type, materials can have polar characteristics according to a certain criterion. For example, fiber cement and metal siding are nonflammable, while plastic siding is not highly fireproof.

When choosing a material, one should focus not only on the pros and cons of the material, but also on the structural features. So, for a wooden and log house, it is better to choose ventilated facades. In this regard, even the most high-quality and expensive plaster will be inferior in its characteristics to siding or cladding panels.

But brick or stone buildings (which are environmentally friendly in themselves) are preferable to decorate the outside with decorative plaster. Being completely natural, it helps to remove moisture from the building, maintain heat in the cold season and create pleasant coolness in the heat.

It is also important to take into account climatic conditions. For example, wood trim, which has a number of advantages, will quickly deteriorate in coastal areas. It is better to sheathe the house with panels or slabs. This waterproof material will withstand squally gusts of wind and will literally repel moisture.

Modern facing material must be moisture resistant. Some surfaces (plaster, siding and panels, clinker tiles) have low moisture absorption, while others (most types of bricks) cannot boast of similar characteristics.

The moisture resistance of the material directly affects how the facade withstands frost. With high moisture absorption, moisture accumulates in the pores of the coating, which freezes and expands at low temperatures.

As a result, the surface becomes covered with cracks, the performance properties of the cladding are lost, and its appearance suffers.

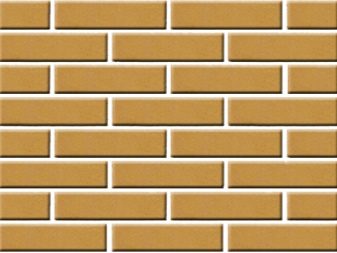

Clinker tiles

Visually, the material is a brick of the correct shape. The material is based on shale clay subjected to high-temperature firing. In the process of the latter, the clay changes its yellowish tint to terracotta, brown, beige (depending on the initial state of the clay and the characteristics of the technologies used).

The main feature of clinker is its increased strength, frost and earthquake resistance. The advantages of the material are also high rates of moisture resistance, resistance to temperature extremes, environmental friendliness, and a variety of choices. It is suitable for the design of ventilated building facades and has a fairly high cost. However, the price range is wide enough: from premium models to economy versions.

In addition to clinker tiles, there are ceramic and concrete tiles. They are characterized by strength, wear resistance and low moisture absorption. Concrete tiles do not tolerate temperature extremes, may have disturbed geometry, and have considerable weight. Ceramic tiles are suitable for both dry and wet installation.

Natural and artificial stone

Stone cladding is strong and durable. When choosing a natural stone, this should be done taking into account the climatic conditions. So, marble is unsuitable for regions with high humidity, while limestone is not used in areas with a harsh climate.

Natural stone undergoes complex processing, including its purification, elimination of the radiation background, giving the desired shape. Naturally, all this affects the cost of the finished product, which is very high. The large weight of the material necessarily requires strengthening the foundation. It is worth noting that buildings decorated with natural stone look respectable, and such a facade can last up to 100 years. True, with regular care.

Today, those who want to decorate their home with marble stone are increasingly using an artificial analogue. In terms of its strength and wear resistance, this material is not much inferior to the natural mineral, but at the same time it has a lower cost and lighter weight, and easier installation. Artificial stone is based on polyester resins, modifiers and pigments, as well as fine-grained stone chips.

The latter ensures the strength and attractive appearance of the material, and the resin provides its increased moisture resistance, high antibacterial properties, and the ability to self-cleaning.

As for the appearance, the material imitates any stone surface. At the same time, it is not always possible to detect a "substitution" even on closer examination - the color and texture are so close to the shade and structure of natural stone. Aerated concrete or brick wall is usually hidden under the finish, less often - wooden surfaces.

Brick

It contains only natural ingredients, so you can confidently declare its environmental friendliness. Moreover, the presence of micropores in the material allows the walls to "breathe", which contributes to the creation of a favorable climate in the building. In addition, the material is not afraid of frost, and retains its resistance to UV exposure for a fairly long time.

Using different types of bricks and their masonry, it is possible to create original and unique facades. A big plus: if a fragment of the facade is damaged, spot repairs can be made. Bricklaying is a rather laborious process that requires a professional approach. It is also important to use it only on a reinforced foundation and after carefully waterproofing the basement. Of the significant disadvantages is the low heat capacity.

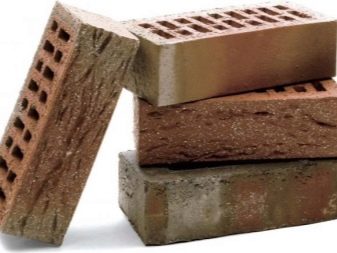

Brick can differ in composition and production methodology, and therefore it is customary to distinguish the following types of it.

- Clinker. The basis of the brick is plastic clay, which is fired and pressed. If we talk about the technical properties of the material, then it is the best among other types of bricks. The clinker modification is characterized by high mechanical strength, heat resistance and resistance to direct sunlight. The frost resistance of the material is 300 cycles. Clinker brick is resistant to aggressive environments, has a low coefficient of water absorption. Undoubted advantages are also environmental friendliness and ease of maintenance - it is enough to wash the facade. The disadvantages are high cost and high weight. An alternative to this type of brick can be thinner, and therefore lightweight, clinker tiles.

- Ceramic. A widespread type of brick, which has a variety of colors and is characterized by durability, resistance to temperature changes, fire resistance and low cost. Unfortunately, the water absorption of ceramic bricks can reach 10%, which also affects its frost resistance. If limestone is present in the composition, this will cause even more increased moisture absorption.

In this case, the limestone will appear in the finished product with darker inclusions.

It is among the lots of ceramic bricks that there are often materials with broken corners and not the most impeccable, from the point of view of geometry, shapes.

- Hyper-pressed. The basis of such a brick is cement, special additives and shell rock, which are subjected to semi-dry pressing. Visually, the material is difficult to distinguish from ceramic, but it is characterized by lower moisture absorption (at an average level and is 5-6%) and, accordingly, better frost resistance, more accurate brick geometry. This durable and strong material is easy to install, however, the bricks are heavy and tend to change shade during use.

- Silicate. The composition of the silicate brick is a cement-sand mixture, the production method used is autoclaving. This ensures the affordability of the material. In addition to its low cost, it is distinguished by the correct geometry of shapes, good sound insulation properties, and strength. Moisture absorption is up to 15%, which causes the instability of silicate bricks to frost. Large weight combined with high thermal conductivity and less attractive aesthetic qualities - all this becomes the reason why buyers rarely choose sand-lime bricks for facade cladding.

Sheathing

House cladding, in contrast to cladding, performs 2 functions - decorative and load-bearing. The latter manifests itself primarily in frameless buildings. The outer skin has a large load, therefore the materials used are based on metal (more often steel), which necessarily has anti-corrosion protection. House cladding is usually done using special metal sheets or thermal panels.

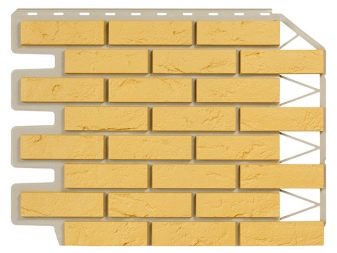

Thermal panels

They are a material consisting of a foil layer with a fastening system, insulation and a decorative layer. As a heater, polystyrene foam and its extruded version, as well as polyurethane foam, are used. Preference should be given to polyurethane foam products. The insulation in them contains the smallest air bubbles, which provides excellent thermal insulation performance with a low weight of the product.

Clinker tiles are usually used as a decorative layer.

As a result of cladding, an imitation of brickwork is obtained, the choice of shades and textures is diverse.

The material is durable, 1.7 times warmer than many of the materials reviewed. It is quite simple to mount it, however, it is important to follow the fastening technology. The material should be fixed directly to the wall, avoiding the formation of an air gap between the panels and the façade.This is due to the vapor tightness of the thermal panels.

The walls should be leveled first, otherwise it will not be possible to avoid the skewing of the cladding, which will lead to the loss of its operational properties. The service life of the cladding is up to 30 years.

Sheets

Steel is usually used as the basis for external cladding sheets. It is covered with a layer of zinc, which allows you to achieve decent anti-corrosion performance. Additional protection against environmental influences (primarily UV effects), as well as the decorative effect of the material is provided by applying a polymer coating.

The strength of the material and its wind resistance are ensured due to the peculiarities of the shape: a profiled galvanized sheet is used to create a ventilated sheathing. Similar sheets are used as roofing sheets for roof decoration.

This finishing method is applicable not only for residential buildings, but also for household buildings, garages. Profiled sheets are robust and durable, and new fastening systems ensure ease of installation and durability. By choosing this or that shade or direction of "furrows", you can create unique exteriors.

Installation is carried out on a prepared frame. For insulation, you can choose polystyrene, mineral wool materials or purchase a profiled sheet, thermally insulated at the factory. The latest models are 2 profiled sheets, between which a layer of insulation is laid.

Combined solutions

Increasingly, owners of private houses are resorting to combined cladding of cottages. This method involves a combination of several textures within the boundaries of one facade. It is noteworthy that the difference in textures is achieved both by using different materials and by using the same material with imitation of different surfaces.

The latter method is more convenient in terms of installation and preparatory work, as well as maintenance. In most cases, the basement of the building, corners, small architectural elements, door and window openings are distinguished by a different material. Combined finishing of the facade allows to emphasize the complexity and sophistication of buildings of complex configuration and add zest to buildings that are simple in shape.

For classic exteriors, a combination of stone and brick is suitable, as well as a combination of these materials with plaster.

For houses in the Gothic or rustic style, a combination of stone and plaster is chosen, adding forged elements to the exterior design. For a country house in a rustic style, stone, wood and brick are used. For modern buildings in the spirit of minimalism - a combination of plaster and concrete, wood and brick.

Manufacturers

The leader among the manufacturers of wet facades is the company "Ceresit", whose products make up 20-30% of the domestic market. Plaster mixes "Knauf", "Kreisel", "Biteks" are also in demand. Strength and increased wear resistance make it possible to use the products of these brands for finishing not only private, but also public buildings.

- Those who are looking for high-quality thermal panels should pay attention to the products of a domestic manufacturer. "Workshop of facade materials" (IMF). Innovation, state-of-the-art equipment and meticulous quality control at all production stages are what allows the manufacturer to occupy a leading position. The thickness of the insulation, depending on the collection, is 30-100 mm. The appearance is also represented by several collections: "Classic" (traditional brickwork), "German collection" (popular in Germany clinker), "Stone collection" (imitation of stone surfaces), "Spanish collection" (imitation of the texture of ancient Spanish castles). The average price is from 1,500 to 3,500 rubles.

- Another manufacturer of thermal sheathing panels, Termosit, can boast of the quality and safety of its products, which are not inferior to European counterparts.The thickness of the insulation, depending on the model, is from 30 to 80 mm. Cost - within 1000-2000 rubles per sq. m.

- The best siding manufacturers are brands Docke (a large selection of wood-like panels, as well as profiles of unusual pastel shades), VOX (a large assortment of panels imitating rare types of wood, colored profiles of a delicate shade), Alta-profile (the undoubted leader of the Russian market, producing siding with imitation of wooden surfaces, colored profiles as well as innovative frost-resistant panels).

- A wide selection of curtain wall systems is presented by the company "Ozersk Mineral Coatings Plant"... The main products are facade slabs based on fiber cement, as well as additional elements, subsystems.

The finished panels are painted according to the customer's order in the shades presented in the RAL catalog.

Beautiful examples

Wooden panels familiar to everyone allow you to get unusual design solutions. It is enough to combine materials of different colors, changing their direction within the same facade.

The most popular options for cladding with wood or wood imitation are eurolining and block house (imitation of a log). Country houses and dachas designed in this way look cozy and noble, and under the cladding many building materials can be hidden (frame, brick, blocks or a pre-fabricated frame).

For country and Provence-style buildings, you can use a painted board or its siding imitation as a finishing material.

Houses finished with artificial stone or panels and siding with imitation of a stone surface look no less beautiful and even outwardly durable. Brick cladding is a classic. To create it, you can use not only brick, but also clinker tiles or siding with imitation of masonry.

Colored siding panels look original and allow you to create a unique exterior. Designers recommend combining 2-3 types of panels, similar in tone, or using contrasting solutions. The direction of the profile can also be different.

Vertical siding is able to visually "stretch the room", and the use of panels laid at an angle will add volume and expressiveness. It is not recommended to use horizontal single-color panels for covering long, simple buildings. It looks monotonous and unattractive.

The use of the same decorative plaster with a different method of application allows you to get completely different externally facades. Plastered in light shades of surfaces are familiar, this is an excellent solution for exteriors in a classic style, for example, traditional English or modern.

Colored plasters look no less interesting.

It should be noted that the greatest organicity is usually achieved by combining various textures. Wood and stone, brick and stone, stone and plaster harmoniously "coexist" within one facade.

For information on how to choose a design for home decoration, see the next video.

The review is good. According to the criteria of price-quality-durability, I choose plaster.

For insulation, I advise PPS thermal panels, we survived two winters with them. Beauty in the house, dry and warm. The main thing is, when you decide on the material - do not take EPS, they are more expensive and worse in quality. A friend of ours used them to insulate them, during the winter several tiles fell off, the adhesion was poor. I had to redo it, and this is an additional waste.

The comment was sent successfully.