Everything you need to know about mineral wool slabs

Mineral wool slabs - heat-insulating material, which is used to insulate various buildings, private and multi-storey buildings, industrial structures. Thanks to the use of an insulator, it is possible not only to create comfortable indoor conditions, but also to reliably protect the building from rapid wear and tear. Before buying mineral wool, it is recommended that you familiarize yourself with its technical characteristics, varieties and markings.

Peculiarities

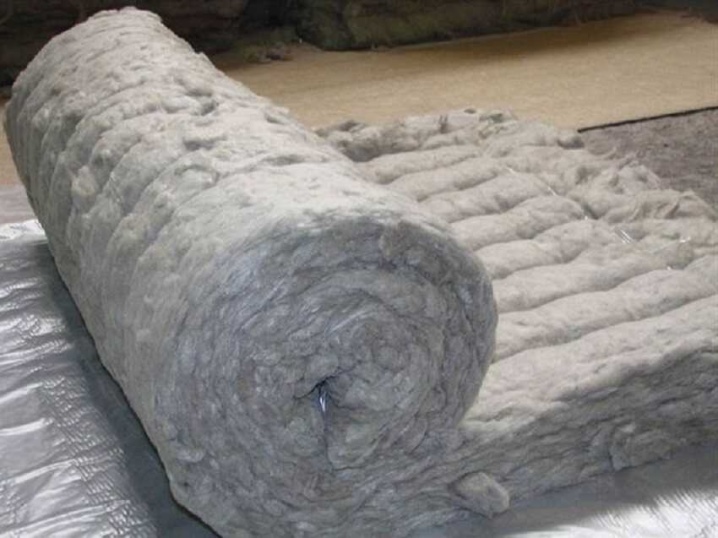

Mineral wool plate heaters are soft, semi-soft, hard, with increased rigidity or hard. All these types have a fibrous base, which provides the material with good heat and sound insulation properties.

The heat insulator has many other advantages, due to which it is widely used in all construction areas. Its advantages include:

-

durability - the service life of mineral wool boards, provided that they are correctly installed, is about 50 years;

-

increased strength indicators (they directly depend on the stiffness of the plate);

-

biological resistance - fungi and mold do not form on the surface of the insulator, even if operated in a humid environment;

-

unattractiveness to insects, rodents and other pests;

-

fire resistance;

-

no deformation under loads;

-

the absence of cold bridges due to the material retaining its original dimensions (do not shrink);

-

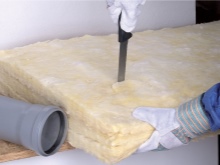

easy installation of sheets, due to their low weight per 1 / m2, convenient cutting with a construction knife or hacksaw;

-

a small mass of heat insulator.

Mineral wool slabs have some disadvantages, which manufacturers of insulators are trying to neutralize. The main disadvantage is the decrease in the quality of the building material when it gets wet. Moistening mineral wool leads to a significant increase in thermal conductivity.

To improve the moisture resistance of the heat insulator, some manufacturers treat it with specialized hydrophobic substances.

Another disadvantage is the abundant formation of dust when cutting or sawing fiberglass, due to which workers recommend the use of personal protective equipment - glasses, respirators and overalls. Miniplates are not environmentally friendly. In their production, formaldehyde-based substances are used to increase moisture resistance - they are released into the environment and have a negative impact on human health.

Main characteristics

Tiled mineral wool is manufactured in accordance with GOST 9573-2012. It is characterized by certain technical parameters.

-

Thermal conductivity coefficient from 0.041 to 0.045 W / (m * K). Reliable protection against thermal leakage is achieved due to the fibrous structure of the material.

-

Density. Manufacturers offer various miniplates. They are light with an average density of 10-35 kg / m3, elastic (35-120 kg / m3) and rigid (120-180 kg / m3).

-

Water vapor permeability. Mineral fiber insulation has a high vapor permeability - its value is 0.48 g / (m * h * hPa). When installing the insulator, it is important to provide for the outlet of steam to the outside so that it does not accumulate in the mats.

-

Flammability. Plates made of mineral wool fibers are non-combustible - these materials are classified as class G1.Depending on the type, they can be operated at temperatures from 300 to 650 degrees. When heated, the insulator does not emit toxic substances into the environment. When ignited, the insulator smolders, while practically no smoke is formed during combustion.

-

The size of the mineral wool. Standard slabs are 1000 mm long and 500 mm wide. The thickness of the insulation can be different - it is selected taking into account the operating conditions. The popular insulators are available in thicknesses of 50mm, 100mm and 150mm.

Different brands have different weights. Basically, the mass of 1 slab is from 37 to 45 kg.

Overview of types by type of cotton wool

For the production of mineral fibers, glass, stone or slag are used as the main component. Depending on the substances used, the insulation is divided into stone, slag or glass wool. Outwardly, these types of insulator are similar, but they have different production technologies and have different physical properties.

Glass wool

This is the most budgetary type of insulation. For its production are used:

-

dolomite or limestone flour;

-

cullet;

-

borax;

-

sand;

-

synthetic binder;

-

soda.

The structure of the material is fibrous. The length of its fibers is in the range of 15-40 mm, and their width is from 5 to 15 microns.

Glass wool - the softest type of insulation from the group of mineral wool heat insulators. It is recommended to use it where no mechanical stress will be exerted on the material. Moreover, fiberglass is the most prickly. When working with it, dust is formed, consisting of the smallest glass fragments. When it gets on the skin, eyes and respiratory organs, as well as on mucous membranes, it causes severe irritation.

To prevent serious health consequences, personal protective equipment should not be neglected when working.

Stone

Such mineral wool slabs are also called basalt. Unlike other types of heaters, stone ones are made of various shapes, density and resistance to mechanical stress. They are among the most environmentally friendly materials.

Basalt wool can be of high or low density. In the first case, the products have increased rigidity, in the second - flexibility. Low-density materials are recommended for the construction of low-rise structures, and high-density materials for the insulation of apartment buildings.

Basalt wool, in contrast to glass wool, has a large weight, elasticity and resistance to open flames. It has a fibrous structure. The length of its fibers is not less than 16 mm, and the thickness does not exceed 12 microns. The main disadvantage of such plates is high vapor permeability, which is why, when installing the insulation, it is required to provide additional protection of the insulator from moisture.

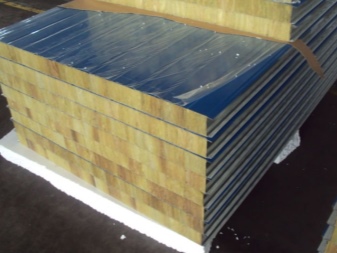

Some manufacturers produce hydrophobized boards - such insulation is provided with a foil backing. To impart greater density, the products are stitched with glass threads.

Slag

For its production, blast-furnace slag is used, which is a glassy mass. This is a waste product formed during the melting of cast iron in special devices in industrial plants. Insulation is obtained by pulling fibers on special equipment. Their length is 16 mm, and their width ranges from 5 to 13 microns.

Unlike other types of mineral wool slabs, slag have the least fire resistance. When exposed to temperatures above 300 degrees, the material is sintered and loses its performance. In addition, the slag-based insulator has poor moisture resistance. Due to the high levels of hygroscopicity, when installing insulation, you need to take care of the waterproofing layer.

It is recommended to use slag slabs only for internal insulation of premises.

Marking

On the packaging of the heat insulator, manufacturers indicate information by which you can find out about the dimensions of the slab, date of manufacture, fire resistance, variety and thickness of the facing layer. And they also give information about the density of the material.

Plates are marked with an alphanumeric designation:

-

P-75 - lightweight slabs with a density of 75 kg / m3, intended for thermal insulation of horizontal structures;

-

P-125 is a semi-rigid insulator with a density of 125 kg / m3, recommended for insulation of ceilings and floors inside a building;

-

ПЖ-140 - rigid slab with a density of 140 kg / m3, used for sound and heat insulation of walls and roof structures;

-

ППЖ-200 is a plate of increased rigidity, capable of withstanding a load of 200 kg / m3.

Solid slabs are marked with the markings PT-220, PT-250 and PT-300.

Popular manufacturers

On the market, tile heaters are represented by products of domestic and foreign production.

Heat insulators of several brands have gained popularity in terms of price and quality ratio.

-

Isover... Under this brand, types of tile insulation are produced with various sizes and technical characteristics. The catalog contains universal, facade, roofing and floor heaters.

-

Knauf... The manufacturer offers high quality insulators for roof insulation and wall insulation. He manufactures mineral plates based on basalt and fiberglass. Knauf products can be used to improve the sound insulation of a room.

-

Rockwool... Under this trademark, both universal plates and specialized heaters are produced. The manufacturer offers hydrophobized heat insulators, two-layer products with a smooth and rough surface, rigid sheets and bio-resistant foil solutions.

-

Technonikol... The company produces tile insulation for domestic and professional use. The brand produces soft, semi-soft and hard tiled mineral wool.

-

"Termopol". The manufacturer offers rigid slabs made of basalt rocks using water repellents. Insulation materials "Termopol" are intended for use in civil and industrial construction.

Miniplates of these manufacturers leave a positive impression on both home and professional craftsmen. They are easy to install, adjust to the required dimensions and practically do not generate dust.

Nuances of choice

The purchase of mineral wool sheets must be approached responsibly, since the effectiveness of the heat insulator will depend on the correct choice.

In order not to be mistaken, it is recommended to follow the recommendations of experts.

-

It is important to consider the conditions under which the insulator will be used. The material should be selected in strict accordance with the needs. For example, to insulate the floor and walls, you do not need to give preference to facade solutions - in this case, the minelite will quickly lose its operational properties.

-

It is necessary to take into account the pressure to which the structure will be subjected - with serious weight loads, it is necessary to choose sheets with the maximum stiffness indicators. Otherwise, the insulator will quickly seal and lose its thermal insulation qualities.

-

For internal insulation of the roof, it is best to give preference to plates with a foil layer.

-

When choosing a heater, you need to pay attention to the location of the fibers. Plates with a vertical direction of fibers retain thermal energy well, and with a chaotic direction, they are more durable. The latter are recommended to be used where it is necessary to withstand heavy weight loads.

Before buying, you need to check the certificates of conformity for the goods in order to protect yourself from purchasing counterfeit products.

Applications

Mineral wool slabs are widely used to improve heat and sound insulation of buildings for various purposes.

They are used to insulate:

-

overlapping;

-

pitched and horizontal roofs;

-

floors and ceilings;

-

interior partitions;

-

facades and frame walls.

Miniplates are actively used for warming and improving sound insulation of old and new building structures. They have gained popularity and consumer confidence due to their favorable cost, wide range and high efficiency.

The comment was sent successfully.