Crushed stone compaction coefficient

The demand for crushed stone does not decrease over time. It is an indispensable building material for a hard surface of the road, pouring the foundation and blind area, as well as when performing a number of other works. For the supplier and the consumer, one of the most important parameters is the size of the compaction of crushed stone.

What is it needed for?

When crushed stone is delivered to the object and dumped in the working area, within which it is leveled, the amount of crushed stone compaction comes into play. Its feature is the actual shrinkage of crushed stone poured into a specific place, the layer of which will reach a certain level.

Compaction of crushed stone occurs during delivery - during shaking and vibration, while the dump truck moves to the place of acceptance of building materials. Under the action of shaking, the pebbles are positioned extremely tightly relative to each other. The voids formed during the initial dumping of rubble into the truck become somewhat smaller by the end of the vehicle's path, but it is impossible to completely get rid of them.

Crushed stone compaction coefficient is a value equal to the ratio of the volume established during shaking to the initial volume, which the crushed stone batch has just occupied in the body before delivery.

The ratio between the initial and final volume should not be less than 95%. If there is less crushed stone, the customer will resolve the issue of the lack of crushed stone and adjust the amount to be paid. For example, instead of 20 m3, he was delivered only 16.5 - the percentage of crushed stone crumbling was more than 15%. In this case, 17.5%. The initial and final volume values include these values. When placing an order, the consumer requires these values to be displayed - otherwise, the supplier will end up unwittingly deceiving the client.

Determination of the coefficient

The main material from which crushed stone is made is granite or limestone. In terms of fractions, it differs in the size of a pebble in the range of 5-120 mm. Its other parameters are crushing density, absolute (in terms of solid granite or limestone) density, freeze resistance and tamping ratio (with road shaking and forced compaction after delivery).

During transportation

Warehousing of crushed stone, which has been in the warehouse for more than one year, leads to a certain decrease in the bulk volume. Under the influence of their own weight, small stones sink into natural voids formed between large ones. The highest density of crushed stone is at the “bottom” of the heap.

When transporting rubble, you can see that he sagged a little during delivery. This process occurs most fully during long-term (long-distance) delivery and when driving on not completely flat and smooth roads. GOST allows compression of each cubic meter by an amount not less than 15% of the original bulk volume. More precisely, the compaction coefficient (according to the same GOST) is 10-15%, depending on the size of one pebble.

The slightest inconsistencies with this standard must be recorded in the contract for the purchase and supply of building materials.

The consumer has the right to measure the body of the car upon arrival of the cargo at the facility if he has any claims to the ordered volume of crushed stone. The difference between the bulk and final density will reveal whether the entire batch of crushed stone has been delivered.

When tamping

Preparing a place for the foundation of buildings and structures, supports for a fence or a gate, a base for a road, rubble is tamped. The most popular way to compact crushed stone is with a road roller: stones exclude the accelerated spread of the object in different directions, cracking it during operation. An alternative to a roller is a vibratory plate: it shakes and sows down the rubble in a method partially based on sliding. For this purpose, craftsmen use an additional coefficient - the amount of compaction.

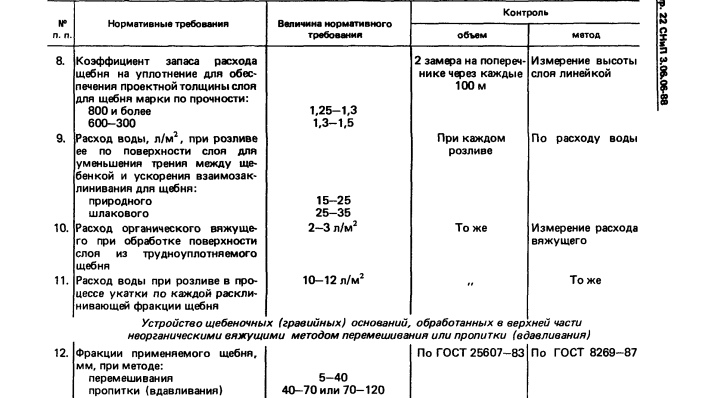

The consumer has access to the values given in the table in accordance with GOST (for a certain fraction), independent or third-party (in the laboratory) calculation.

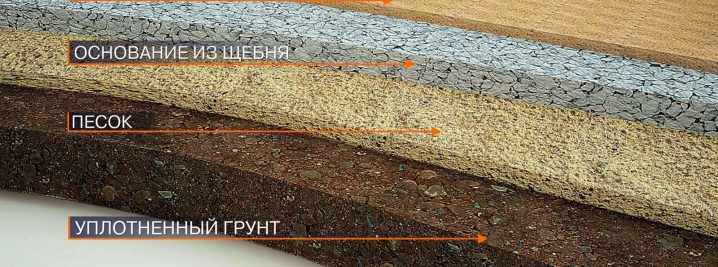

After rolling out the crushed stone, it is necessary to check whether the earth has ceased to settle under the rammed base. The presence of a sand cushion under the rubble is required.

As an example, a base for a strip foundation. The thickness of the crushed stone interlayer is 30 cm.The area of a country house under construction is 80 m2, the width of the base under the foundation in any of its places is 40 cm.Let's say that crushed stone with a stone size of 2-4 cm is chosen as a working building material, and its strength mark is listed as M-1000. The value of the tamping value for the M-1000 (the average stone size is 3 cm) is 1.38.

In terms of the dimensions of the foundation structure, the volume of crushed stone will be 4.13 cubic meters. Multiplying this coefficient by the real volume of crushed stone (after compaction), it turns out that its bulk volume is equal to 6 "cubes". This quantity - with a margin - is indicated in the current application.

To speed up the calculation, the user can take into account the following values of the bulk density of crushed stone of the desired type.

|

Species or variety |

Stone size |

Bulk specific weight, kg / m3 |

Marking (strength class) |

|

Crushed granite |

20-40 |

1370-1400 |

M-110 |

|

40-70 |

1380-1400 |

||

|

70-250 |

1400 |

||

|

With limestone structure |

10-20 |

1250 |

|

|

Gravel (including granite) |

20-40 |

1280 |

|

|

40-70 |

1330 |

||

|

0-5 |

1600 |

||

|

From slag |

5-20 |

1430 |

|

|

40-100 |

1650 |

||

|

above 160 |

1730 |

||

|

800 |

M-800 |

||

|

Based on expanded clay |

20-40 |

210-340 |

M-200, M-300 |

|

10-20 |

220-440 |

M-200, M-300, M-350, M-400 |

|

|

5-10 |

270-450 |

M-250, M-300, M-350, M-450 |

|

|

Rubble (including black) |

1200-3000 |

M-110 |

Measuring the KU of secondary crushed stone with pores is an additional difficulty. Here, a part of the pores can collapse if the movement is too active. Filling from the body from a great height, transporting tens of kilograms of building material with a wheelbarrow, carrying with an excavator bucket and the like - can make their own adjustments. As a result, a noticeably increased density of the building material is formed at the "bottom" of the backed-up part of the base.

The use of highly porous secondary crushed stone when arranging a reinforced foundation is not allowed. The fact is that porous materials are used only to create insulated floors or as an additional layer of interfloor overlap, and are not put into the main concrete in any way.

Compaction factor of black crushed stone is more difficult to calculate.

For example, when burnt clay brick, which has served its life in the once erected walls, acts as black (rough) crushed stone, pieces of cement mortar, which were masonry joints, can get into it. The bulk density of such waste is recalculated as follows:

- a quantitative assessment is made of pieces of brick and hardened cement separately - as a percentage;

- the real density of the fragments of the masonry joint is determined - if it is known what proportion of cement and sand the previous builder adhered to (based on GOST and SNiP);

- the density of the brick is determined;

- the average indicator of real density is calculated;

- the bulk density is determined - using an empty container with a known weight.

The compaction factor of the debris is calculated based on the received data. It is important that the material is not highly porous.

Measurement features in the laboratory

In laboratory conditions, the initial parameters are checked and the desired ones are calculated. A company that extracts and delivers crushed stone, sand and other building materials must provide an accurate calculation, without which, according to SNiP requirements, further construction is impossible.

A house, building, structure, even a non-capital building, erected without ramming, is fraught with an imminent deterioration: the building is actively sagging, cracking after the erection of the walls supporting the supports. A hasty repair, even with the observance of safety measures, the requirements and norms of which are based, among other things, on resistance to materials, ultimately fraught with even greater costs and additional engineering surveys.

Most often, a building or structure that has received such violations is subject to demolition in order to avoid damage and loss of life.

Bulk density is calculated or selected when splitting and tamping crushed stone - in order to calculate the required cubic capacity and the exact composition of concrete. Crushed stone in an unconsolidated state is calculated using the following formula:

- determine the mass of the container participating in testing;

- the container is filled with rubble and weighed it again;

- the resulting difference is divided by the volume of the container.

Craftsmen should remember: the "cube" of crushed stone screening immediately after pouring weighs 1.5 tons, and a cubic meter of crushed stone with a stone size of 4-7 cm - 1.47 tons. Stones exceeding 70 mm in size are used mainly for road and iron embankments roads.

Crushed stone ramming is the most critical stage. If we are talking about the construction of a skyscraper, then the crushed stone poured onto a layer of sand in the pit is carefully rolled using a roller and vibrating plates.

Repeated measurements after compaction of crushed stone are made in order to identify inconsistencies with the requirements of GOST: if necessary, crushed stone is tamped to the desired condition.

Frequent, unnecessary for further construction, the passage of workers on the newly compacted rubble is not allowed. The surface layer of stones can be rammed and displaced from its level, and the building can get cracks already in the first year of active use.

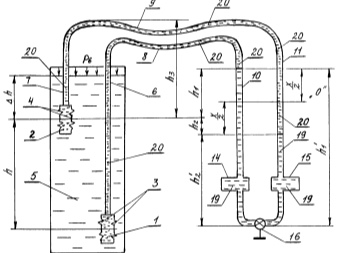

In conditions suitable for the calculation, a technique of the BPD-KM type is used. It is a density meter with a water-cylinder design that determines the real specific gravity. It is used to control the quality of compaction of the base, which includes granite gravel and crushed stone of various formations, including limestone. The accuracy of the device is 10 mg / cm3. The device meets the requirements of GOST No. 28514-19.

The comment was sent successfully.