Cement particle board: characteristics and application

Cement particle board (DSP) is a material that is actively used in construction and repair work. Such plates are in demand in a huge number of areas. But even these fundamental structures are presented in a wide variety in the construction market. Before opting for a specific product, you need to familiarize yourself in advance with the features of these structures and their areas of use.

Features of production

Cement particle board is manufactured using special technologies. The process of creating a DSP includes the following steps:

- the solution is based on water, which is poured into a special mixing container. Aluminum, salts and water glass are also added to the container;

- in order for mineralization to take place, elements of shavings are added to the mixture;

- the next step is the addition of cement;

- to obtain a DSP block, the solution is poured into a special form;

- a certain thickness is given to the substance using a press;

- after pressing, the product undergoes heat treatment, in the implementation of which the characteristics of the components of the raw material are taken into account;

- in order for the substance to solidify, it is placed in special chambers. There, at a temperature of 80 C, the components are fixed;

- after hardening, the web is cut into sheets. Their sizes are determined by GOST.

Products are manufactured only in special factories, where strict control over the implementation of each stage is carried out. It is impossible to make a high-quality DSP panel on your own.

Specifications

Cement-bonded products have a number of fixed technical characteristics that explain many of their properties:

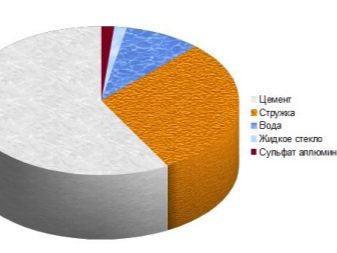

- the composition is a quarter made of wood chips, a little more than 8% is water, the main component is Portland cement and the share of additional impurities is 2 and a half percent;

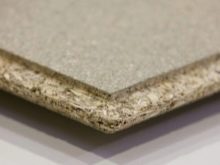

- material thickness varies from 8 to 12 mm;

- the width of the slab is 120 or 125 cm;

- length - from 2.6 to 3.2 m. On order, you can choose a model with a length of up to 3.6 m;

- the weight of one square meter of DSP with a thickness of 8 mm reaches 10 kg.

The material has a high density, which reaches 1300 kg / m3. In the process of moisture absorption, the density can increase by 2 percent. The water absorption capacity is usually less than 16%.

The roughness of the DSP board is the relief of each sheet. It depends on the features of the grinding. Unpolished slabs have an index of 320 µm, while the material that has undergone grinding has an index of 80 µm.

The sheets have a fire resistance class G1, which means that the material has low flammability. The thermal conductivity is 0.26 W.

All of the listed characteristics allow you to choose the required number and parameters of the building material.

There are also different types of materials for slabs and molded products made from CBPB:

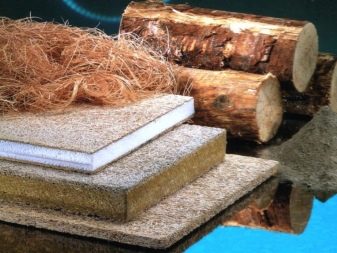

- Xylolite - high-strength material with good thermal insulation. Such slabs are often used for flooring. Products are presented in a wide range of colors.

- Fibrolite is a raw material consisting of long fibers. It has high thermal insulation properties and a soft texture. Biological factors do not have a strong effect on this type of CSP.

- Fine chip materials include arbolite, which is used in various fields.

Advantages and disadvantages

Like any building material, DSP has a number of advantages and disadvantages. The advantages of such plates include:

- The material is highly resistant to moisture and temperature extremes. Plates can withstand up to 50 frost cycles. This characteristic significantly affects the service life of the plates.

- The raw materials used to create such partitions are absolutely safe for human health. CSP does not emit harmful toxins and does not cause allergic reactions.

- Cement particle board is perfect for various transformations. With it, you can use any finishing methods and change the surface of the product as you wish.

- Wide range of. A rich variety of products can be found in modern home improvement stores.

- Affordable price is an important advantage. Since the material is often used in the construction of a home from scratch, purchasing a large amount of material will not negatively affect your budget.

- Plates of this type are very durable.

- An important feature when using DSP as interior partitions is their good sound absorption. They create the required level of sound insulation and additional comfort in the room.

- Unlike some other materials, DSP is not exposed to parasites, harmful insects or rodents that can periodically appear in a private house.

- The material is not subject to instantaneous combustion. The stove can only catch fire when exposed to an open flame.

- DSPs are very durable. Such plates can last for more than a dozen years.

- Cement-bonded products are easy to use. It is convenient to carry out various repair work on such a surface using a drill, perforator or knife.

- The fixed size of the products makes the installation process much easier.

- The material is resistant to decay processes.

- When cement bonded particleboard is used for screed floors, it offers significant cost savings over, for example, self-leveling compounds or cement-sand leveling options.

The negative properties of DSPs include:

- Products can reach a large mass, which greatly complicates their use in high rooms. The high weight is due to the high density of the material.

- The material is not plastic. If you try to bend such a plate, then you can break it. The risk of breakage during construction work explains the need to purchase material with a stock.

Based on the data presented, it can be seen that the DSP has significantly more pluses than minuses. The disadvantages of such products are easily compensated for by their advantages.

Scope of application

Cement particle boards are used in various construction and finishing fields. The most common uses are:

- Outdoor. It implies the suitability of the slabs for finishing the facade of a living space, the use of slabs as a basis for fences. Work on the implementation of permanent formwork is also not excluded. DSP sheets can be used in both private and industrial areas. These slabs are used as protective structures for garden beds in private houses, as well as parts for industrial enterprises.

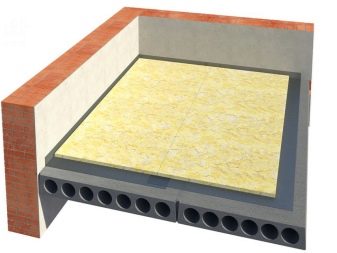

- Cement particle board is irreplaceable in the construction of a frame house. In this case, it acts as an excellent insulation. Products are used to create a warm floor. They are also often used for walls, subsequently creating an interesting decor on the slabs.

- The resistance of the material to moisture allows it to be used as a ceiling covering in saunas and other types of premises where the level of humidity is high.

- Often these sheets are used to create partitions in rooms.To make the plates last longer as a separator, they are covered with a special paint that performs a protective function.

- The best varieties of cement-bonded particle boards are used to create furniture.

- The material is used to create window sills. It is becoming a more affordable alternative to wooden structures, and at the same time it serves for at least a long time.

- It is permissible to make a special base for roofing in private houses from dense slabs.

- Restoration is a very common area of application of the slabs. The material is often used to give older buildings a better look. In addition, due to their relatively low price, the products are quite suitable for large-scale work.

- Thin slabs are often used to decorate such attributes of private houses as a fireplace and chimney.

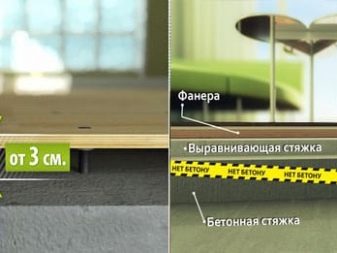

- Cement particle boards are sometimes used as an alternative to cement for screed floors.

DSPs are suitable for various types of work. You can carry out the following options for processing cement-bonded products:

- cutting to the required size;

- creating holes in slabs with a drill;

- milling work;

- increasing the strength at the joints using face grinding;

- applying a primer, acrylic or silicone paints;

- facing with ceramic products;

- pasting with fiberglass.

These capabilities characterize the DSP material as an excellent base for any coating and as a source for the embodiment of creative ideas.

Manufacturers

There are a number of manufacturers of DSP products that are very popular in the construction market and have earned positive feedback from customers.

Leningrad firm "TsSP-Svir" provides light gray products with a calibrated surface. Also among the assortment of the company there are polished models. The production is based on European standards and high-quality equipment from Germany.

Bashkir enterprise "ZSK" also distinguished by the production of high quality slabs in accordance with GOST. The main feature of the product is its increased resistance to temperature fluctuations and the effects of weather conditions.

Kostroma company "MTI" characterized by special geometric characteristics of products and strict adherence to all quality standards.

Tambov firm "Tamak" produces high quality slabs. The company approaches its business very carefully, so it is difficult to find even the slightest marriage among their products.

Omsk firm "Stropan" is engaged in the production of resilient cement-bonded particle boards of various thicknesses. The company is also distinguished by the creation of sheets with increased sound and heat insulation.

Knowing the list of leading companies, you can easily choose such stoves that you will not be disappointed in later.

Installation tips

Depending on how exactly you decided to use the DSP for your home, you should listen to various recommendations for the correct installation of these plates.

The most common option is to insulate walls or floors with cement-bonded particle boards. To carry out this procedure, it is necessary to prepare the surface of the walls in advance, providing it with a crate made of metal and wood. It is necessary to have special cells with a fixed size of 500 * 500 mm.

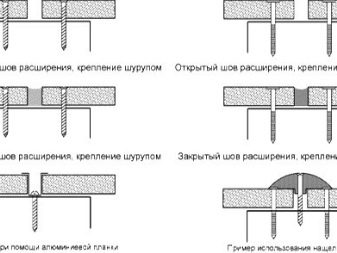

During installation, leave a space of 1 centimeter between the slabs. It is covered with a special overlay, as which you can use finished products from the same material or create them with your own hands from residual raw materials.

To fix the canvases, you must use nails, screws and self-tapping screws. Fastening can be carried out in alternative ways - using mastic or a special adhesive solution.

To insulate the frame structure, the slabs must be installed from the outer and inner sides of the walls at the same time.If you want to insulate a utility room, then it is permissible to leave a small space between the base of the wall and the DSP sheet.

In private homes, many people place cement-bonded particleboards on wood floors to warm them up. To correctly carry out this process, you must follow a special algorithm:

- In order to avoid creaking floors in the future, the base is adjusted and fixed with self-tapping screws. When adjusting the base coat, it is imperative to remove the rotten boards and replace them with new ones. If there are cracks or cracks in the surface of an insignificant nature, they must be treated with a putty.

- Measurements of rooms are carried out taking into account the location of the long side of the canvases across the boards.

- It is necessary to design the layout of the DSP on paper.

- With the help of a grinder, you need to cut the sheets to the required parameters, if necessary.

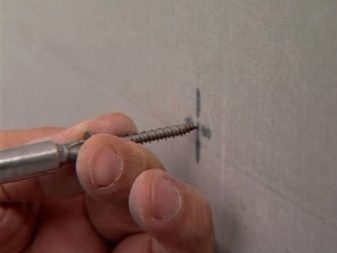

- Slabs are installed in the direction from corner to corner. In this case, it is best to fix the products with zinc self-tapping screws.

- The seams between the laid sheets should be primed. Only after the completion of all stages can the exterior finish of the flooring be carried out.

A special process is the use of DSP for floor screed. In order to properly carry out the dry screed procedure, it is necessary to lay the sheets on a special filler with granules and metal profiles made of plasterboard or wooden blocks. Self-tapping screws for fastening cement-bonded particle boards must be suitable for the cross-section of the beams and the material from which they are constructed. This method of leveling is used only if the difference in level differences is more than 6 cm, raising the level with the help of canvases is permissible on average to a height of 7 to 10 cm.

To ensure that no errors occur during the implementation of the screed using the DSP, it is important to follow the strategy for carrying out this work:

- it is necessary to carry out a breakdown of the final level on the walls of the room, that is, to determine the height of the new floor covering;

- a couple of layers of plastic film should be laid, which is used as a material for insulation;

- the damper tape should be attached to the surface of the walls located around the perimeter of the room;

- beams are installed with a step equal to the size of the rule, since it is unacceptable that the distance between them exceeds 0.5 m;

- after the beams are clearly level, they should be fixed using dowels and self-tapping screws;

- the space between the installed guides must be filled with bulk material, then it must be tamped;

- after that, the DSP is laid and fixed with self-tapping screws to the beams at a distance of 10 to 15 cm.

- after cleaning the surface from dust and debris, you can lay the finishing floor covering.

Additional recommendations

In order for the installation of cement-bonded particle boards to go perfectly, it is necessary to listen to a number of additional recommendations:

- In order to work with the DSP neatly, you should not do it alone. Remember that the larger the slab, the greater the fragility. Therefore, especially when installing large products, the work must be done with an assistant.

- Do not stack the products close to each other, otherwise the surface will be damaged in the future if the products swell due to moisture.

- To avoid cracking the products, place the holes with fasteners not at the very edges of the slabs, but stepping back from their borders by a couple of centimeters.

- If the fixing of the canvases is not carried out on a wooden surface, but for example, on a metal profile, then only metal screws are needed for fastening.

- In the process of cutting slabs, it is best to use a hacksaw blade. It will help to avoid strong dust formation and will allow you to cut the products quite evenly.

Cement chipboard is a material that has proven itself on the Russian market for a long time.To use this raw material correctly, you must take into account all the recommendations of professionals. Taking advantage of the versatility of the slabs and tips for their installation, you can perfectly decorate the whole house with this material and enjoy its quality for a long time.

In the video below you can see how to hem the ceiling with DSP sheets.

The comment was sent successfully.