Plinth profile for insulation: types and characteristics

In the process of wall insulation, the basement profile becomes the support of materials for decoration and thermal insulation. It also has a protective function. With imperfections of the facade surface and its various defects, the use of only the starting profile is not enough, additional elements are required, with the help of which a straight and even line will be created.

What is it needed for?

The basement walls are exposed to temperature changes. Therefore, there is a possibility of condensation in both heated and unheated basements. It is capable of negatively affecting the surface. But also the lack of thermal insulation of the basement becomes the reason for significant heat loss in the room, which means that the heating costs of residents in the cold season will increase significantly.

The problem of unnecessary costs and damage to the surface of the walls can be solved by using thermal insulation materials on the basement. Insulation must be correctly selected, for this it is necessary to study its varieties, quality, characteristics and properties.

You can highlight the main functions of the profile. First of all, it serves as a solid foundation for the installation of thermal insulation materials. And also with its help, it is possible to exclude the effect of moisture on the insulation, which will lead to a longer service life of the product.

Finally, the profiles protect the outer area of the plinth, where rodents can enter without using it.

Varieties

Experts note that when residents independently insulate a house, the use of a basement profile is often neglected. This is a serious mistake. In this type of work, the use of a profiled base can prevent the occurrence of many problems during operation. The technology itself involves the use of these elements.

Currently, various types of profiles can be used for basement insulation work. They can be divided into 3 main ones: these are aluminum products, PVC and two-piece strips.

Aluminum products

The base profile of this type is made on the basis of aluminum. Due to the material of manufacture, the product has excellent resistance to moisture.

Due to a special treatment, the surface of the element has a protective film, which makes the material more resistant to physical influences. At the same time, working with products requires accuracy, since the material is easily scratched, and this can lead to the formation of corrosive processes.

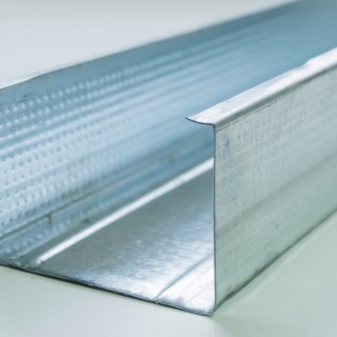

Products are made in the form of U-shaped strips of various sizes. The standard length is considered to be 2.5 meters, the width can be different and be 40, 50, 80, 100, 120, 150 and 200 mm. For example, a basement profile with a thickness of 100 millimeters is used at the initial stage of insulation work, and decorative base plates are also installed on it.

Its use is relevant for the wet method of outdoor finishing work, when the surface is plastered, putty and painted. Aluminum profiles for the base / plinth with a drip edge not only secure the thermal insulation materials, but also serve to drain water.

The thickness of this type of profile ranges from 0.6 to 1 millimeter. Manufacturers give a product warranty for more than 30 years. The aluminum facade profile has become widespread and is presented on the market in a wide range.

Aluminum profiles are produced by both domestic and foreign companies. Among Russian brands such brands as Alta-Profile, Rostec, Profile Systems.

PVC profile

The shape is similar to the aluminum profile strips. Made of high quality plastic. The material tolerates low temperatures and humidity well, and is resistant to corrosive processes. Products do not deteriorate and do not deform due to temperature changes. Another undoubted advantage is the lightness of the material, due to which it does not create problems during installation. And also it is distinguished by a lower price category than aluminum products.

PVC basement profiles are most often used for independent finishing work. Their standard dimensions are similar to those of aluminum materials. Most often, profiles of 50 and 100 millimeters are used for finishing private and country houses, this indicator depends on the thickness of the thermal insulation material. The only drawback of plastic products is the lack of resistance to UV rays.

Two-piece plank

This basement profile has its own characteristics. Consists of U-shaped and L-shaped end and rear parts. One of the shelves is perforated. This helps to more securely install the fasteners.

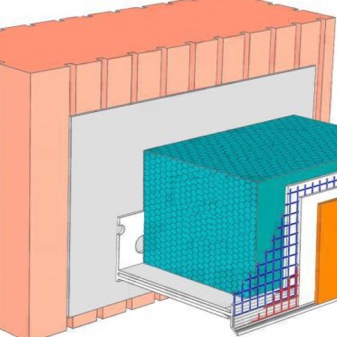

The front must be inserted into a narrow groove. Reinforcing fiberglass mesh and drainage systems are important components. Due to this design, it becomes possible to adjust the distance between the shelves.

Components

It often happens that the facade does not have a flat surface. In this case, you need to use additional elements. They help to make the façade line perfect. For aluminum and PVC profiles, there are connectors that look like plates with U-shaped edges.

If the product cannot adhere to a wall with an uneven surface, it is advisable to use expansion joints. This element has special holes for mounting. The thickness can be different and depends on the gap obtained between the profile and the base.

Dowels can be used to secure the starter profile. In the event that expansion joints are not enough, spacers can be used. Their diameter can be different and is also selected depending on the width of the gap.

Mounting

The installation of profiled material for the basement can be done both with your own hands and with the help of specialists. The cost of work can be calculated by FER. It includes a full set of rates. Although there are no particular difficulties in this process, however, adherence to technology is an important factor, because it depends on how correctly and reliably the materials will be fixed.

First of all, you need to apply the markup. This can be done with a special level and rope. A fixed rope is stretched horizontally from one side of the base to the other, and marks are made along its length, in the place of which holes will be drilled. It must be borne in mind that for work you will need a smaller drill than the screws themselves, which will be screwed in.

The ends of the outer profiles must be cut at an angle of 45 degrees. This will help you create an even 90 degree corner joint.

The installation of the basement profile must be started from the corner of the building. When installing the battens, you first need to fix the beams. They should be located strictly horizontally, and the width should be the same as the width of the insulation. The bottom bar must be parallel to the ground.

If necessary, use expansion joints. Before final fixing, each piece must be applied to the base. Further, self-tapping screws are installed for fastening, and the profiles are securely fixed. To fasten the elements together, strips are used. If a base with a drip is used, it will help prevent moisture and precipitation from entering the system.

When the work is completed, it is time to install thermal insulation materials. The insulation is located in the profile recesses. If it needs to be glued, then glue is applied first. After completing the installation work, you need to fill the gaps between the profile and the base with special foam that has moisture-resistant and frost-resistant properties.

For information on how to install the plinth profile, see the video below.

The comment was sent successfully.