The subtleties of the process of warming the foundation of a wooden house

The main functions of the insulation for the foundation are to reduce the heat loss of the structure and protect the base from destruction and freezing. However, this can only be achieved through external thermal insulation, provided that suitable materials are used.

Peculiarities

Wooden houses are fairly lightweight structures compared to brick or concrete counterparts, so it can have a lightweight foundation. Depending on the characteristics of the soil on the site, one or another type of foundation is selected. As a rule, this is a shallow strip, pile or pile-strip base. However, regardless of the type of system used, it is mandatory for all types of bases to insulate them.

Experts recommend insulating the basement from the inside, and it is important to do this along horizontal surfaces and vertical blind areas. Insulation of the foundation from the outside allows you to solve a number of problems.

Reduced heat loss at home

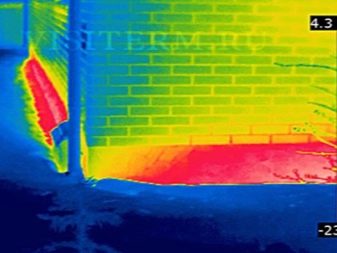

An uninsulated foundation causes up to 20-25% of the heat loss of an object, even in the presence of thermal insulation of the walls and floor. This is due to the formation of "cold bridges" in the foundation, through which heat escapes.

Reducing soil swelling in winter

Insulation of the base from the outside allows you to prevent significant freezing of the soil near the insulation. This, in turn, prolongs the service life of the structure, reduces the likelihood of seasonal soil deformation, which means violations of the horizontal and geometry of the foundation.

Fewer freeze / thaw cycles

Each foundation material is frost-resistant, wood is no exception. Frost resistance refers to the number of freeze / thaw cycles that the foundation can withstand without losing its technical properties. It should be understood that in one winter such frosts and defrosts can take place over 10, which, of course, affects the durability of the foundation, and therefore the entire building. The use of insulation allows you to reduce the number of freeze / thaw cycles of the foundation.

Foundation protection

The foundation, protected from freezing and moisture penetration, is characterized by strength and reliability. When soaked, the wood undergoes warping, begins to rot, lose strength, as well as its characteristic heat and sound insulation.

Providing a favorable indoor climate

When insulating the foundation from the outside, it is possible to move the dew point as much as possible closer to the surface of the insulating cake, which prevents the walls and insulation from getting wet, and avoids an increase in humidity inside the room. On the contrary, with proper heat and vapor insulation in a wooden house, the optimum moisture content will be maintained.

Maintaining the health of communications

Often, a communications network is laid in the basement of a house. The use of insulation ensures their protection against freezing and failure.

Materials (edit)

Materials for insulating the foundation of a wooden house must meet the following criteria:

- low thermal conductivity;

- vapor permeability;

- moisture resistance;

- high wear resistance;

- ease of installation.

The most important are the characteristics of thermal conductivity, vapor permeability and moisture resistance. The less the material conducts heat, the warmer the house will remain. The tree is characterized by the ability to absorb excess moisture and, if necessary, give it away. That is why it is so important to use "breathable" insulation, which can remove excess moisture vapor, preventing them from turning into water drops directly on the surface of the walls or insulation. The vapor permeability of the insulation should be close to the vapor permeability of the foundation material, if this is not possible, the use of vapor barrier is mandatory.

Among the most popular materials for insulating a wooden base, there are several types.

Expanded polystyrene

This is a well-known foam plastic. However, today experts recommend using its best option - extruded polystyrene foam. The latter is characterized by low thermal conductivity, resists moisture better than foam plastic, and has a large margin of safety.

Such disadvantages of insulation, such as environmental insecurity (during use, a certain amount of styrene is released) and flammability (depending on the type of product, the material belongs to the G1-G4 class) when it is installed on the foundation become insignificant.

The ease of fixation also attracts users - expanded polystyrene is produced in the form of rectangular plates, has a flat surface. For fastening, a special adhesive is used (it is important that it does not contain solvents), as an additional fastening - umbrella-type dowels.

A variety of polystyrene foam insulation is also a penoplex made on the basis of extruded polystyrene foam. In terms of its operational characteristics, it slightly exceeds the latter, while outwardly it is no different.

An important point when using insulation based on expanded polystyrene is their instability to UV rays, therefore, the insulation should be covered with protective and decorative elements for the basement and not stored unpacked.

Expanded clay

Natural insulation, which is small, air-filled "pebbles". Differs in low thermal conductivity, environmental friendliness, fire safety, good vapor permeability, but absorbing moisture. Wet insulation, as you know, loses its technical characteristics. This can be avoided by high-quality waterproofing.

As a rule, expanded clay is used in log cabins, as well as houses with a floor on the ground. In this case, a semblance of a dam is organized - at a height of 50-60 cm from the ground, a blind area is made, the walls of which are waterproofed and covered with expanded clay.

For insulation, it is better to use material of different fractions - larger fragments will provide an insulating effect, small ones will fill the space between them.

Polyurethane foam

A modern insulation with heat efficiency indicators similar to those of expanded polystyrene materials. Besides, it differs in moisture resistance, safe, from the point of view of environmental friendliness, non-combustible.

Warming with polyurethane foam means spraying it over the surface with a layer 3-10 cm thick. Like expanded polystyrene, the material is unstable to UV radiation, therefore it is necessary to protect it after setting. In addition, in this case, the contact finish cannot be mounted, therefore, even before spraying the composition, you should take care of the crate, on which the basement materials will be fixed according to the principle of a ventilated facade.

Penofol

Roll material based on polyethylene foam, which has good thermal insulation characteristics. Besides, one of the sides of the product is equipped with a foil layer, the peculiarity of which is the ability to reflect heat. In other words, the insulation acts on the principle of a thermos - in the cold season it keeps the heat inside the house, in the summer heat it provides coolness inside the room, preventing it from overheating.

In addition, the presence of a foil coating improves the moisture resistance and strength of materials. The release form provides ease of installation.

Features of insulation

Ideally, the insulation of the foundation should be done at the stage of its creation. However, even in a built house, you can insulate the base with high quality, however, the process will be more laborious.

First of all, you need to free the foundation, clearing it to the ground. Around the foundation, you should get a trench with a width that is convenient for working in it. If the structure is at the construction stage, then you can use special equipment to speed up the process, if in an already built house, you will have to dig with your own hands.

Further, the foundation over the entire surface should be cleaned of dirt, if necessary, remove irregularities and cracks, dents. For a smooth surface, use a concrete or wood sander. A special mortar with a high adhesion speed allows you to get rid of cracks and potholes on concrete bases. If you use a conventional cement-sand mortar instead, you will have to wait about 2 weeks for it to set. Leaving the foundation unprotected for such a long period is undesirable.

It is important that the surfaces are clean and dry (maximum moisture content is 4-8%). This is the only way to achieve the adhesion of the insulation.

Before proceeding with insulation, it is necessary to make waterproofing. In the first step, a primer is applied. It is important to achieve the unity of the coating - so that there are no areas of the foundation unprotected with a primer. It is more convenient to work with a synthetic roller with a short nap, in hard-to-reach areas - with a brush.

After the primer has dried, the roll waterproofing is glued. Fixation is carried out by fusion; there are also more expensive self-adhesive versions of products. Waterproofing should be glued from bottom to top.

Moving from top to bottom, the molten bitumen layer will drain, so workers risk getting burned.

Next, the insulation is attached. If these are polystyrene foam plates, then they are glued (fixation on a water-soluble bitumen primer is also possible). Plates are stacked end-to-end, you should try to avoid the formation of gaps between the elements.

A layer of insulation, located below the ground level, just needs to be glued. After filling this part of the base with soil, the insulation will be reliably pressed. It is extremely undesirable to use fasteners here, since this means a violation of the waterproofing layer - groundwater will be able to contact the foundation.

Insulation in the aboveground part can and even need to be additionally fixed with umbrella-type dowels. Under them, a hole of a suitable diameter is first drilled, and only then fasteners are screwed in or driven in.

When using penoplex, a layer of roofing material is usually lined on top of it in the underground part. For the basement element, waterproof membranes are usually used, on which decorative material is then attached (on the crate).

The installation of expanded polystyrene has already been mentioned above. An important point is the preliminary preparation of the crate, spraying is usually carried out by professionals.

A completely different installation is typical for expanded clay. To do this, you need to dig a trench and equip it with formwork. Further, a concrete mixture with expanded clay is poured into the space between the latter and the foundation. After this layer has solidified, it can be additionally insulated with expanded clay, and then waterproofed.

If we are talking about insulating the pile foundation with expanded clay, then they act differently. Trenches 30-40 cm deep are dug between the supports, and grooved bars are attached to the supports themselves.Planks are inserted into them, after which they get a kind of "pocket", space. It is covered with expanded clay.

The process of warming the foundation is completed by filling it, tamping the earth around, decorating the basement or the space between the piles and overlapping the first floor.

For information on how to insulate the foundation of a wooden house, see the next video.

The comment was sent successfully.