Insulation of the walls of the house outside with mineral wool

Since ancient times, various materials at hand have been used to insulate housing. Now this process looks much easier, because more modern heaters have appeared. Mineral wool is just one of them.

Advantages and disadvantages

Mineral wool has a fibrous structure. It consists of molten rocks, as well as several binders such as minerals and resins. The top of the mineral wool is covered with a thin layer of kraft paper. Most often, with the help of mineral wool, the walls or facade of the house are insulated from the outside.

Such material is suitable for both brick and log houses, and for construction from a log house.

Advantages

Mineral wool is chosen for insulation for several reasons:

- it has a high level of fire resistance;

- does not deform even after several years;

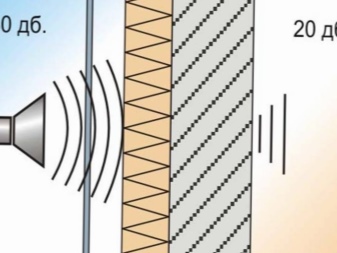

- the level of sound insulation and vapor barrier is very high;

- it is an environmentally friendly material that is completely safe for the human body;

- the service life of this material is about 60-70 years.

disadvantages

Despite the large number of positive aspects, mineral wool also has several disadvantages. So, in the composition of mineral wool there is formaldehyde resin. At too high temperatures, it can oxidize and release phenol, which negatively affects the human body.

However, when insulating the outer walls of the house, you do not need to worry about this.

Choice of mineral wool

There are several types of cotton wool.

- Basalt or stone. Such material differs from others in its long service life and low thermal conductivity. It is made from waste of metallurgical production. The material is completely safe for humans and environmentally friendly. It is easy to cut and also quick to assemble. This material is distinguished by a high level of sound insulation. For this reason, it is used to insulate facades under a layer of plaster. The disadvantages of basalt wool include too high a cost. In addition, during work, small pieces of cotton wool may come off, forming basalt dust. The density of basalt mineral wool is 135-145 kg per cubic meter.

- Mineral glass wool. For its manufacture, an alloy of staple fiberglass is used, which makes it sufficiently strong and dense. The material has a low cost, is resistant to frost, does not shrink, does not ignite. The density of the material is 130 kilograms per cubic meter. This wool is considered the best among mineral insulation materials.

- Slag mineral wool. It is made from the blast furnace slag melt. Its density is in the range of 80-350 kilograms per cubic meter. The cost of the material is not too high. This makes cotton wool especially popular with buyers. Experts do not recommend using this type of cotton wool for places with frequent precipitation and sudden temperature changes.

In addition, mineral wool is also distinguished by its fiber structure. It can be vertically layered, horizontally layered, as well as corrugated. Also, the insulation is marked.

- Cotton wool, the density of which is within 75 kilograms per cubic meter, is designated P-75. It can be used only on those surfaces where the loads are small.

- The P-125 marking denotes mineral wool with a density of about 125 kilograms per cubic meter.It can be used for finishing horizontal surfaces.

- For finishing walls made of metal profiled sheets, as well as reinforced concrete floors, cotton wool marked PZH-175 is used.

What might you need?

Thermal insulation of houses with mineral wool cannot be done without certain devices and tools. This will require:

- metal reinforced mesh;

- building level;

- spatulas of different sizes;

- puncher;

- dowels;

- hammer;

- special glue;

- primer;

- container for glue.

Installation of lathing

Mineral wool can be used for the following cladding: for corrugated board, plaster, siding, brick. In this case, the walls can be made of wood, foam concrete, brick. However, initially you will need to make a crate. It can be built both from a wooden bar and from a galvanized profile.

If it is not possible to do without fasteners, then the crate is best made of wood.

But it also has disadvantages, because it has a heterogeneous structure. This can lead to a change in the shape of the log material. To prevent this from happening, the wood must be pre-processed.

After that, you can proceed to the construction of the crate. If it is assembled from wooden blocks, they can also be used to secure the cladding material. The distance between the bars depends entirely on the width of the mineral wool. However, it is worth making sure that it exactly matches the size of the blocks - otherwise, the insulation will be ineffective. As for the placement features, they can be attached both horizontally and vertically.

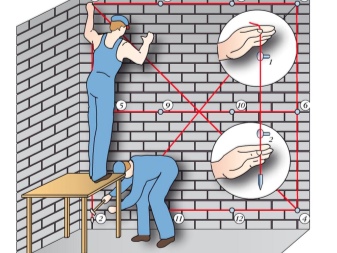

As a fastener, you can use special galvanized nails or dowels. Each individual section of the batten must be checked with a level so that the plane of the frame is even. In addition, it is imperative to make a crate around the entire perimeter of windows and doors.

Technology

Those who prefer to insulate the house with their own hands should first read the instructions and find out how to properly glue mineral wool to a wooden and brick wall or aerated concrete base.

First of all, you need to start preparing the surface of the outer walls. They must be cleaned of dirt and dust, and all irregularities must be eliminated. If there is old paint or plaster, it can be removed with a spatula or solvent.

Upon completion of the cleaning work, it is necessary to make a markup using sags made of strong nylon ropes.

Preparation and installation of insulation

We proceed to the preparation of the mineral wool surface. For this you can use special adhesives such as Ceresit CT 180. This composition must be applied to the prepared mineral wool slabs using a special spatula. The glue layer should be no more than 0.5 centimeters. For it to be better attached, one or two coats of primer must be applied to the mineral wool.

When the wool slabs are prepared, they need to be carefully glued to the facade. In those places where the cotton wool meets the window, it is necessary to ensure that the joint of the insulation does not border on the edge of the window opening. Otherwise, heat leakage may occur. You also need to check that the mineral wool tightly covers the space between the beams.

When the mineral wool is well glued, it is worth doing additional fixation. This is required in order to increase the safety of the entire structure, because the weight of the cotton block is twice the weight of the foam blocks. Dowels can be used as additional fastening. However, additional work can be carried out only in a day, when the glue is completely dry.

For one block of mineral wool, you will need to use 8 fasteners. To do this, you need to make holes in the blocks of cotton wool, the depth of which will be several centimeters more than the length of the dowel itself.

After that, it is necessary to insert fasteners into the prepared openings, and then install the dowels in the middle and fix them well.

Next, you need to start installing "patches" in the corners where the openings and walls meet. Thus, the entire facade structure is strengthened. Light "patches" are made from pieces of reinforced mesh. At the very beginning, a layer of glue is applied to the desired places. After that, a reinforcing mesh is installed on these sections.

When all the "patches" are ready, you can start installing the reinforcing mesh. To do this, you also need to apply an adhesive, on which the mesh is fixed. If the insulation is done for siding, then only a layer of mineral wool will be enough - laying a reinforcing mesh in this case will not be required.

Waterproofing

To protect the room from moisture penetration from the inside of the house, a vapor barrier must be placed under the mineral wool. For this, it is best to use a diffuse membrane that allows air to pass through perfectly. It should be attached directly to the wall using a regular construction stapler.

It is also permissible to attach individual strips of the membrane. It is best to use brackets to fix them. All seams must be well insulated with adhesive tape.

Summing up, we can say that insulating the walls of the house with mineral wool will help to cope with such a problem as heat loss.

At the same time, any owner can cope with such a task. It is enough just to adhere to simple rules and use quality material.

For tips on insulation with mineral wool, see the next video.

The comment was sent successfully.