Features of the mineral slabs Rockwool "Butts Facade"

Among the wide variety of materials intended for thermal insulation of external walls, the products of the Danish company Rockwool stand out, represented by the series of rigid plates "Facade Butts". The main feature of the materials in this series is that they are not only good insulation, but also the base for applying finishing decorative plaster. At the same time, mineral wool boards do not require additional processing and reinforcement before finishing.

Main characteristics

Insulation from Rockwool is a densely compressed gabbro-basalt fiber obtained in the process of thermal action on rocks. The fibers are arranged chaotically in relation to each other, tightly intertwining with each other. Also, water-repellent components and binders are added to the composition of the insulating material. As a result, mineral wool slabs acquire characteristic features.

The main characteristic of the stone slabs of the series is the combination of high density and strength with low weight, which facilitates installation and does not create additional load on the foundation.

Stone fibers that form the basis of the material make it resistant to any mechanical stress, they are not biodegradable. This means that neither mold nor rot is formed on the slabs (one of the most dangerous "pests" for building materials). In addition, the hard fibers of the slabs are too tough for rodents.

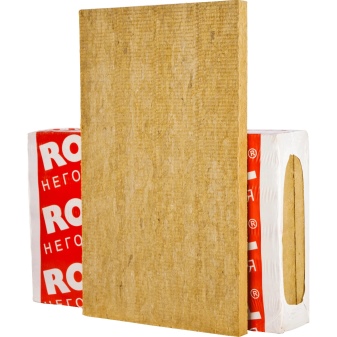

The most common size of slabs is 1000x600x50mm, but the range includes materials 1200 mm long, 500 mm wide and up to 200 mm thick.

Scope of application

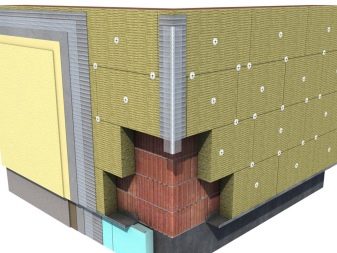

Thermal insulation plates "Facade Butts" can be used:

- on facades of any type;

- when arranging fire-prevention cuts outside the building;

- for framing window and door openings.

At the same time, Rockwool mineral wool is suitable for insulating buildings, regardless of their complexity, number of storeys and degree of fire resistance. Insulation is also successfully used in the reconstruction of buildings, which require the reconstruction of the architectural features of the time of construction.

Types of products

The range of heaters in this series is represented by plates of four brands.

- "Facade Butts D Extra" - insulation, consisting of two layers of different density. In the lower layer, this indicator does not exceed 94 kg / m3, in the upper layer it is equal to 180 kg / m3. Hard layer thickness - 25 mm. This combination makes it possible to simplify the installation of the plates without compromising the thermal insulation qualities of the material. In addition, this combination significantly reduces the load on the building wall and its foundation. Therefore, this mineral wool is suitable for insulating multi-storey residential buildings and office buildings.

- "Facade of Butts Optima". With a density of 110-120 kg / m3, plates with such markings can reduce heating costs by 40% and provide additional sound insulation in a house or apartment.

- "Facade Butts Extra". Due to its rigidity and strength, the insulation retains its geometry for a long time, without crumpling or breaking during installation and operation.

- "Facade of Butts D Optima". The two-layer construction with a denser top layer (170 kg / m³) is suitable for thermal insulation of low-rise buildings and public buildings.

All facade insulation materials are attached to concrete, brick and other types of stone walls.

Advantages and disadvantages

The composition and characteristics of Rockwool thermal insulation material determine a number of its advantages.

- Good heat and sound insulation. In terms of its thermal insulation properties, a 100 mm slab is much superior to a brick wall 1 m thick. At the same time, the slabs are able to absorb not only street noise, but also vibrations arising in building structures.

- Porosity of the material. Due to its porous structure, while retaining heat, stone wool does not impede the passage of steam and condensate from the room into the external environment, allowing the walls to "breathe". It is important that the fibers of the mineral wool themselves do not absorb moisture, since they are impregnated with a water-repellent composition.

- Durability. Even after the lapse of time, the boards do not shrink or deform. Therefore, such thermal insulation can serve up to 50 years without losing its performance.

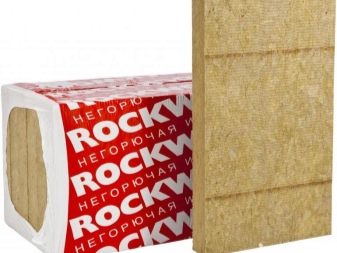

- Fire safety. The material is classified as non-flammable. Even with strong vapors and a temperature of 1000 ° C, basalt fibers do not ignite and retain their shape.

- Simplicity and ease of installation. Sheets can be stacked in various directions.

- Environmental Safety. Despite the fact that the mineral wool contains synthetic substances that serve to bind the rest of the components, the insulation is considered completely environmentally friendly, which is confirmed by the EcoMaterial Green certificate.

- Versatility. Basalt insulation can be installed both under plaster and under siding. It is also suitable for arranging other types of ventilated facades; ceramic tiles can be glued to it.

- Range. A variety of types of products allows you to choose the most optimal option for each specific case.

The disadvantages of basalt insulation most often include its rather high price. Although it is obvious that the high technical characteristics of the material are worth paying more for them. Also, the disadvantages of Rockwool materials include the need to level the walls before installing them. This is due to the high rigidity of the slabs.

Installation

Despite the fact that wall insulation with the help of "Facade Butts" materials is a fairly simple process, during its implementation it is necessary to take into account a number of nuances and follow certain rules.

To increase the efficiency of the heat insulator, before installing mineral wool boards, you must:

- remove old finishing coatings and remnants of building materials from the wall;

- level the surface (the maximum permissible deviation is 1 cm for every 2 m);

- clean the surface from dust;

- treat the wall with a primer.

The Rockwool slabs themselves are attached with glue. The ideal solution would be to use an adhesive from the same manufacturer. NSWhen applying, the glue is first thoroughly rubbed into the mineral wool panels with a spatula, and then additionally applied in a thick strip along the entire perimeter (departing from the edge 2-3 cm), and in the form of small dots to other parts of the plate (there must be at least 5 glue points).

Immediately after applying the glue, the material is applied to the wall. Installation begins with the installation of insulation on the basement profile, which is located 60 cm from the ground.

When installing, it is necessary to avoid the coincidence of the lines of joints and slopes, therefore experts recommend thinking over a plan for placing sheets in advance.

After the adhesive has set, the glued thermal insulation is additionally attached to the facade using disc dowels. This is done no earlier than a day after installation, but no later than 3 days later. For each slab element, at least five nails must be used (the usual placement is in the center and at the corners), but, as a rule, the number of fasteners depends on the thickness of the material and its location. Dowels are screwed in 10-15 mm deeper than the thickness of the heat insulator.

As a finish, decorative plaster is applied to the thermal insulation boards in 2 layers.

It is important to remember that "Facade Butts" insulation is a specialized material designed specifically for insulation of external walls.Therefore, it is not recommended to use it for other purposes (for example, for thermal insulation of roofs or floors), although in some cases such use is still justified.

Reviews

For the first time, Rockwool rigid insulation appeared on the construction market more than 20 years ago. During this time, he managed to gain popularity both among professionals and among those who independently repair and insulate their homes.

Many buyers in their reviews note that after installing thermal insulation from a Danish company, the consumption of resources spent on heating the house has significantly decreased. Accordingly, the financial costs have also decreased. The fact that decorative plaster can be applied directly to the insulation, without the use of additional materials, also reduces the cost of the thermal insulation work itself. In addition to reducing costs, this also allows you to speed up the work on the insulation of the house.

This is especially true for those who, without experience, make the installation on their own.

However, the most important advantage of a building material is its durability. Those who installed the "Facade Butts" slabs among the first (when the products first appeared on the Russian market) still do not know the problems with thermal insulation. It is noteworthy that due to the qualities of the heat insulator, the finish on it lasts much longer.

See the next video for more details.

The comment was sent successfully.