Laying paving slabs in the garage

The garage is a special place for many car owners. For comfortable and safe maintenance of transport and pastime, the space must be properly equipped and equipped. Gender is one of the important characteristics. Many garage owners prefer a concrete floor, but due to a number of disadvantages of classic concreting, it is worth paying attention to paving slabs.

Peculiarities

Paving slabs have long been used to decorate the space not only in front of the house and in the local area, but also in the garage. Though it is considered a classic material for finishing paths and streets, due to its characteristics, it is widely used in the arrangement of interiors with a large load on the floor.

It is believed to be one of the environmentally friendly materials. In its manufacture, only natural ingredients are used.

Harmful compounds, as well as hazardous substances that adversely affect the state of the environment or humans, are not used.

Laying paving slabs in a garage has several advantages:

- simplicity of work;

- no need to acquire special knowledge;

- material availability;

- the tile is resistant to chemicals;

- a wide assortment is presented in stores;

- the product is waterproof.

And also paving slabs are wear-resistant, resistant to friction, impact, mechanical stress, aesthetically attractive and endure extreme conditions (withstand temperatures down to -60 °). Ease of maintenance and beautiful appearance are the advantages due to which this type of floor is gaining more and more popularity. In case of damage, chips or cracks, part of the surface is easy to replace.

If necessary, you can change the fragments by changing the drawing and updating the interior.

Which tile is better to choose?

Paving slabs are a fairly common and readily available product. But for laying it in the garage, you need to take into account many nuances. There are 2 types of tiles: pressed and cast. The advantage of the second type is the variety and saturation of colors. Vibro-pressed specimens are great for a garage. Garage tiles must correspond to the future load on it, therefore the minimum material thickness should be 8 cm. You can use multi-colored specimens if the load on the floor is rather low, since some dyes reduce the strength.

When choosing and buying, the material should not have defects: scuffs, cracks, chips. The internal structure of the sample must be uniform.

A material of 300X300X30 mm is often used. But it is more suitable for rooms with low floor load. Paving stones are also popular. This type is distinguished by good strength, it can withstand even very strong loads. And also the material is aesthetically pleasing. When choosing a product, pay attention to the cost. A low cost may indicate an inadequate product.

How to stack correctly?

There are 2 ways to lay tiles:

- on a cement-sand base (the method is suitable in the absence of a concrete floor);

- on the concrete floor.

The technology is quite simple, so you can lay the tiles yourself. For laying, a flat surface is required, otherwise the tile will not fit well and quickly become unusable. On a cement-sand bed, the material is usually laid in new buildings with a soil floor.

It makes no sense to pour a concrete floor on purpose, including because of the cost of the work.

- First, you should dig the soil to a depth corresponding to the calculations. The average depth is 28–30 cm. The higher the weight of the car, the thicker the pillow.

- Sand must be poured onto the finished surface and tamped using a special machine or improvised means.

- Then crushed stone of the middle fraction is poured, a little sand and the layer is compacted again. In new buildings, geotextile fabric is laid on the pillow.

- Then add a layer of sand, water and tamp.

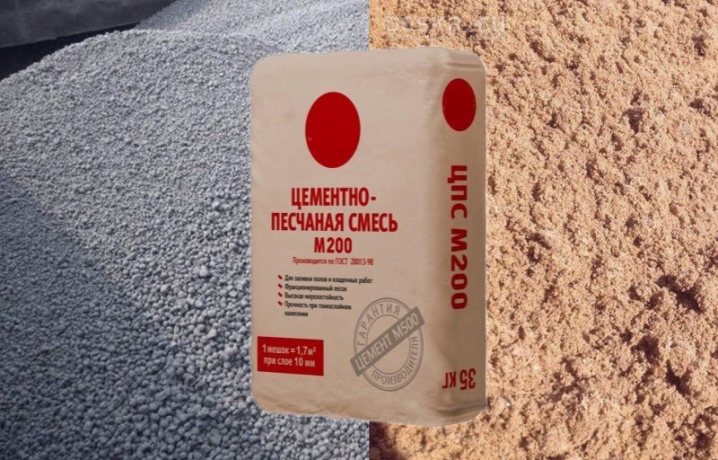

- The last step in surface preparation is a cement-sand mixture.

Laying the tiles begins on the prepared pillow from the far corner of the room, moving along the wall to the entrance. The classic option is considered to be laying in parts of 1 m 2. The thickness of the seam varies from 3 to 5 mm. The parameter is supported using plastic crosses, which can be purchased along with other materials.

Height alignment is done with a rubber mallet. If you use a hammer, there is a great risk of damaging the material.

After laying the floor around the entire perimeter, cement is poured into the cracks between the tiles, and the remains from the surface are swept away with a broom.

The next step is to fill the entire tiled area with water. This is done to harden the cement in the voids and increase the strength of the floor. The entrance is laid in a similar way, starting from the gate.

Laying tiles on a concrete floor can be much faster and cheaper. Before work, you need to make sure that the surface is sufficiently flat and clean. In this case, the paving slabs will be laid on a special adhesive solution, which is applied to the floor and to the tiles with a spatula. A self-leveling flooring compound can be used to improve the quality of the original surface. Filling is carried out according to the instructions indicated on the mixture.

Laying paving stones on concrete is no different from laying on a cement-sand base.

You need to put the sample on the glue and level it a little. After completing the work, it is necessary to sweep the floor and spill water. Similarly, you can equip the race.

When the floor has finally acquired a proper look, you should think about caring for it. To maintain a neat appearance of the surface, special reagents are used. You can buy chemical solutions at car dealerships.

For tips on installing paving slabs in your garage, see below.

The comment was sent successfully.