Preparation for laying paving slabs

Laying paving blocks on unprepared ground leads to their displacement. Due to seasonal freezing, the structure of the soil under the paving stones changes. The paving site is prepared using a special technology.

Site requirements

Before starting work, you need to know the basic requirements for the site.

- For reliable laying of paving stones, it is necessary to accurately calculate the dimensions of the site or path, level and compact the soil.

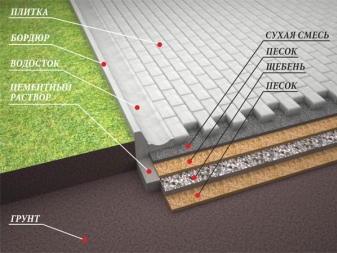

- When determining the paving area and the number of tiles, the width of curbs and gutters is taken into account. Along the outer edge of the curb, an allowance is made for a cement roller that fixes the curb. It is filled up after laying the tiles.

- The area must be level. On a horizontal surface, the blocks of paving stones are tightly adjacent to each other. The path should have a slight slope towards the drain, and the drain itself should be towards the storm sewer.

- The soil under the base is tamped and compacted. This is especially important when paving parking lots. Poorly compacted areas of soil sag under load.

- The site is buried in the ground. The topsoil is usually the looser, so it is removed. The depth of the excavation (earthen trough) is determined by the thickness of the layers of crushed stone and sand of the backfill.

- For lanes with a low load, a depression of 7-10 cm is sufficient. A 10-12 cm depression is considered optimal. This is sufficient for effective drainage. The 10 cm gravel layer is resistant to moderate loads (pedestrians, short parking).

- A multi-layer gravel pad or concrete is poured under sidewalks and parking lots with heavy traffic. The depth of the earthen trough depends on the total thickness of the base and the tiles.

- The intensity of compaction depends on the quality of the soil. Damp, loose areas may require installation of a drainage system. First, they dig trenches, lay pipes, then level and tamp the base under the rubble.

Types of bases

The bases for paving tiles are made of two types - on a gravel bed and with concrete pouring. Areas under parking lots, driveways, on the floor of garages are being concreted. Potholes under the wheels are undesirable, but they are inevitably formed during seasonal melting of snow and the pressure of cars weighing 3-4 tons.

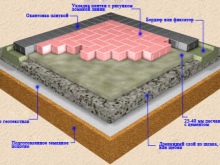

To prevent frost swelling of the soil and displacement of tiles, a layer of thermal insulation is increasingly used. On the leveled bottom of the earthen trough, pavement geotextiles are laid, sand is poured and tamped, plates of extruded polystyrene foam are laid. A reinforcing mesh is laid on it with a gap, then the concrete mixture is poured. This is a solid base for a car park.

A layer of thermal insulation greatly increases the lifespan of sidewalks and garden paths. It can be single-layer or double-layer. A layer of sand (3-5 cm) is poured over it. The thickness of the layers of crushed stone of different fractions is 20-30 cm.

After tamping, the finishing layer of sand is poured onto which the tiles are laid.

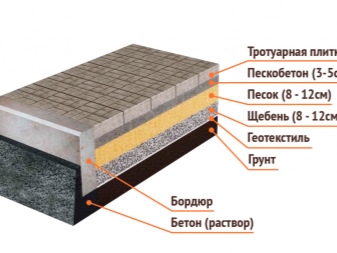

A gravel-sand cake consists of several layers of crushed stone and sand. The largest and heaviest fractions are poured down, followed by layers of fine gravel and sand. The thickness and alternation of layers depends on the density of the soil below them. A waterproofing sheet is laid on damp soils so that moisture does not accumulate in the gravel layer.

The durability of paved areas depends on the quantity and quality of the backfill material. Savings lead to the fact that after 2-3 seasons, the paving stones must be shifted, and the base must be re-leveled and tamped.

How to properly prepare the place?

Preparation for laying paving slabs begins at the stage of leveling the site for construction. Experts advise to prepare a place for storing the removed land. The top layer contains fertile humus; when landscaping is completed, it is used for lawns and flower beds.

The construction of an object or a house is recommended to be organized so that construction equipment will drive into the future parking lot. Gradual soil compaction occurs under the wheels.

When the construction is completed, they begin to markup. You will need a drawing with accurate dimensions, pegs and twine. The size of the recess is 20-30 cm along the perimeter more than the paving area.

Bulldozers and graders are used at large facilities. In the courtyard of a private house, excavation is carried out manually or using mini-equipment.

To level the bottom of the groove and base layers with your own hands, you will need a hand roller or vibrating plate.

Preparatory work begins with the installation of curbs. They are placed on tamped ground and fixed with cement mortar on both sides. It turns out a kind of permanent formwork that holds the multi-layer base and tiles in place. When laying the tiles, gutters are placed on the inside of the curb to drain rainwater. After the solution has hardened, crushed stone is added.

The work is performed step by step:

- filling and leveling coarse gravel;

- compaction of the layer;

- filling and leveling fine gravel;

- rammer;

- filling and leveling sand.

A layer is considered dense enough if a person does not leave noticeable traces on it. Experts recommend using washed gravel and sifted sand. Debris and clay are washed out of the gravel by sediment, and the tiles sink. For better compaction of the sand, it is moistened. Depending on the area of the backfill, use a hose or an ordinary watering can.

The layers of waterproofing and thermal insulation provided by the technology are lined before the gravel filling, after the curbs have been installed. Communications can pass under driveways and paths. For example, an electric cable for garden lighting. They are laid in the ground or in the lower crushed stone layer.

A concrete layer or reinforced concrete slab in the base of the car park prevents the natural drainage of precipitation. It is therefore important to maintain a uniform slope of 5 mm per meter towards the drain groove. The slope is checked with a level or geodetic instruments. Before pouring the concrete mixture, beacons are set up and the surface is leveled along them.

The drainage of rainwater from the concrete base is very important, because when ice forms in the gaps between the paving stones, the coating deteriorates more quickly. Sometimes, when pouring the mixture, special drainage systems are laid. These are gutters made of plastic pipes cut alongside. Before laying the tiles, they are filled with rubble.

The finishing layer of the base, on which the paving slabs are laid, is compacted sand or a dry mixture of sand and cement (gartsovka). Its thickness is 4-7 cm.

Preparation for laying paving slabs in the video below.

The comment was sent successfully.