DIY laying paving slabs on sand with cement

Calculations and measurements are an indispensable component of laying paving slabs on sand with cement with your own hands. They are necessary to determine the exact amount of consumables and decorative materials. Online stores have special calculators that allow you to accurately determine the amount of purchased paving slabs, curbs, cement and sand. There are rules for preparing for the very process of laying, step-by-step instructions for beginners. However, the duration of operation is determined by the correct development of the soil, and the applied methods of laying, and the installation of curbs. It is especially important to correctly perform the support and drainage backfill.

Fundamental rules

Laying paving slabs on sand with cement with their own hands to the uninitiated in the intricacies of the process seems to be a simple matter that does not take a lot of time from the developer.

However, non-observance of the basic rules will lead to the appearance of a short-lived result, already after a short time requiring repair or alteration.

You need to carefully prepare, make the necessary calculations - that is, follow the basic rules that precede each construction stage.

- Purchase in advance all the necessary building materials - cement of a high-quality brand, sand with particles of different diameters, paving slabs of one or several types (here it all depends on the idea of the home designer).

- Prepare the tools you will need for laying: trowel and rubber mallet, rammer, wedges and rakes, pegs with a marking cord, building level and a hose with a nozzle.

- Building materials, unlike tools, will be required only after the soil has been prepared - the fertile layer has been dug out, potential "aggressors" - plant roots and seeds have been removed.

- The depth of the trench is calculated individually. It depends on the hardness or looseness of the soil, the degree of load on the track being formed. It should be deeper if cars will drive on it or the soil is loose and sags quickly.

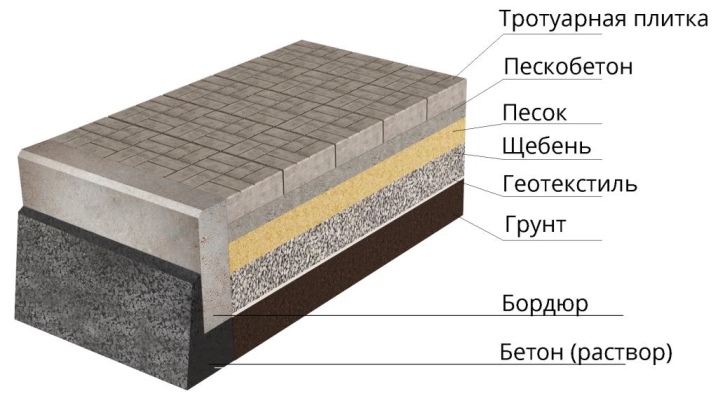

- Laying geotextile or agrotechnical fabric - another indispensable condition for preliminary preparation. This helps to prevent the germination of those segments of plants that have escaped the attention of the home craftsman and can harm the structure in the future.

- Careful implementation of step-by-step instructions for soil treatment, the installation of curbs, the device of support and drainage backfill, the creation of a sand cushion and the technique of laying tiles with your own hands. It may depend not only on the configuration of paving slabs, but also on the presence of limiters in it (only products from a trusted manufacturer with a good reputation have them, and this pleasure is usually not cheap).

- High-quality sealing of joints and design of seams - another basic rule, no less important than careful compaction during installation. Without the latter, it is impossible to create a durable base that provides the ability to withstand the load and not deform.

The basic rules also include safety precautions. Some tools require special protective equipment. So the external simplicity of laying paving slabs on a sand-cement mixture, in the process of implementation, requires taking into account some nuances.

Mixture proportions and consumption

Determining a suitable formulation depends on two points.The first, important, but not the main one is the type of decorative tiles. But now manufacturers produce it in a large assortment, and it is rather difficult to distribute universal recommendations.

The main guideline is the styling method.

- Laying on a sand cushion is justified only in some cases - for example, when building garden paths near a residential building. This is a simple and popular method, inexpensive and not laborious, performed with minimal time and labor, ensuring reliable drainage of water from the tile surface. The ease of repair is also captivating - an element that has become unusable is simply replaced. However, the slightest excess of the permissible load leads to a disastrous result. Sand mixture is not the most reliable option for laying paving slabs.

- Dry cement-sand mixture has undeniable advantages - it has high strength properties, it is more resistant to dynamic loads. Paving with such a composition is within the power of even an amateur, but in this case, the costs of building materials do not provide the desired effect - strength, stability and durability.

- Concrete screed - a base for paving slabs, which is more difficult to prepare than the first two options, but the result is durable.

Laying on a solution of sand and cement differs in approximately the same indicators. Sand-cement is prepared according to a variable recipe, but the basic requirements for it are fixed in the construction GOST. The correct ratio of components is indicated there, so it will not be difficult to make a mixture or solution in the right proportion.

Only sand is used in the sand mixture. It is recommended to mix coarse and fine fractions, no water is added at all. The thickness of the cushion depends on the size and height of the tiles.

A little about the composition and calculations. A dry sand-cement mixture can be used as a grinder (with the addition of lime). On the construction market there are dry mixes with different types of seals. They use fine-grained sand. Industrial additives provide reliable stacking.

Having a shovel or concrete mixer in the house, a drill with a special attachment or a hammer drill, you can prepare a solution for wet laying or a concrete screed. GOST prescribes for this purpose to use only Portland cement without mineral additives. The standard ratio is three parts sand, one part cement. But there is also a little secret - the higher the cement grade, the more sand you need. The recommended thickness of the mortar layer is 0.5 Dm.

The exact amount that will be required for the front of work is difficult to determine. The online calculator can also be wrong. It's all about what consistency the solution is prepared. A lot of thick mortar will be required, but the strength of such a masonry is guaranteed.

The consumption of building materials can be reduced by making a liquid mixture. But this will certainly reduce the quality and durability of the installation. Today it is concrete-sand mortar that is the most popular pillow for laying paving slabs.

but many users equip tracks for indoor use with less financial and time costs and they are quite satisfied with the result. You just need to consider the installation goals and potential loads. This will allow you to determine the type of styling, and sometimes minimize financial costs.

Preparation

For laying with paving slabs, it is recommended to choose dry and level areas so that the masonry corresponds to the plan, does not shrink after a short time from groundwater or precipitation flowing into the depressions.

If we are talking about a surface on which many people will walk or (even occasionally) drive vehicles, you should buy tiles made by vibrocompression.

Vibro-cast tiles are an excellent material for gardening and landscaping. You need to buy with a margin (more by 10% than the calculations showed).Items with defects, damage during transportation or during packing are not excluded.

The base for the tiles is calculated as follows. Crushed stone - 15 cm, sand - 10 cm and dry mix - 3-5 cm.Total, a trench needs to be dug 28-30 cm deep.

With soft soil, ramming is carried out twice - first, the layer is poured with water and rammed, then crushed stone is laid, and the process is repeated. Ideally, the crushed stone is covered with geotextile, and sand and dry mixture are poured over the useful fabric. With a cement grade of 300-400, five parts of sand are needed, and with a grade of 500-600, one in six. PVA glue is sometimes added for strength. The mixture needs to be properly leveled before starting styling. This is especially important when working with dry formulations.

Step-by-step instruction

Preparing a quality mixture is not enough for the success of an enterprise. It is necessary to correctly lay the structural elements:

- the tile is buried in the dry mass up to half;

- each row is individually checked by the level, and defects are eliminated on the spot;

- for this, as a rule, (it can be a simple wooden block), a rubber mallet is used, with which the tiles are carefully leveled, tapping from the end;

- in the same way, irregularities on the surface layer are eliminated - with a mallet and a rule;

- a gap of 2-3 mm is left, using a stop or devices from the manufacturer.

The last stage is the sealing of the seams. A proven technique saves time and effort. First, the mixture of sand and cement is spread over the laid tiles so that it fills the recesses between the tiles. Then the excess is gently swept away. After that, the seams are sprayed with water. The mixture lies flat, swells and reliably holds the elements of the tile mosaic together. Now you only need to remove the spacers inserted between the tiles or special plastic fixtures. They are only needed for cheap tiles. The road has special structural elements.

In publications from professionals, you can find recommendations to periodically repeat the procedure for strengthening the seams, especially after heavy rainfall or spring melting of snow.

Compliance with the prescribed technology and taking into account especially important points, following the basic rules will allow you to create an aesthetic and durable structure in a short time. Its construction is within the power of everyone. This will allow you to update and give an aesthetic visualization to the landscape design of a private house, country or country land ownership.

Step-by-step instructions for laying paving stones with your own hands are presented in the video.

The comment was sent successfully.