Laying paving slabs on gravel

The key to success in laying paving slabs on crushed stone is the correct sealing of the base. Therefore, you need to seriously approach the choice of crushed stone, because for each type of work there are certain selection criteria.

Peculiarities

Crushed stone, according to the principle of the device, is considered a fairly simple matter. You just need to choose the right crushed stone that will meet all the requirements - and you can lay the sidewalk.

In fact, different types of crushed stone have certain characteristics by which they can be distinguished from each other. The list of distinctive characteristics includes: fraction, flakiness (shape geometry), density and strength, frost resistance, adhesion, radioactivity level and shade.

What material do you need?

There are different diameters of crushed stone, and all of them allow you to get a dense, uniform and durable coating. There are 4 main fractions specified in regulatory documents (GOSTs), but there are also accompanying ones. Basically, for work, a fraction of crushed stone with a diameter of 0.5 to 2 cm is used. If the tiles to be laid are thin, then it is possible to sift out crushed stone up to 1.5 mm.

The stone varies in origin. There are crushed stone from rocks, from ore, secondary or slag. One of the most popular types of gravel for paving is dolomite gravel. It is distinguished by its durability, frost resistance, resistance to moisture and low temperatures. Limestone has the lowest strength of all materials, but is often chosen for its low cost. Secondary crushed stone is obtained from recycled construction waste. Its advantage also lies in its low price. Granite stone does not contain any clay or silt impurities. And due to the rough surface, this material has high adhesion properties.

The frost-resistant base extends the life of the pavement area up to 35-45 years.

Flakiness indicates the specific gravity of flat and acicular stones. According to the rules, it should not exceed 15%. If there is too much needle-shaped or spade-shaped crushed stone, the adhesion between the stones decreases and the consumption of the cement mixture increases. For the track, material of 1 or 2 flakiness groups is suitable.

Besides, crushed stone differs in strength grade (maximum withstand load in kilograms per 1 square meter). For small sidewalk paving for the passage of vehicles (the total weight of the load does not exceed 8 tons), the material of the M600-M800 brand is suitable. For an exclusively pedestrian path, the strength of M300-M400 is sufficient.

Also, crushed stone from granite is characterized by increased radioactivity, while limestone and quartzite have a lower natural background. Radioactivity is documented.

The choice of paving slabs should be approached no less seriously.

-

The surface of the material should not have numerous chips, pits or potholes.

-

If you hit two good quality tiles against each other, then a sonorous sound should be heard. This indicates that the material is well dried.

-

In addition, you can try to rub the tiles with each other. If they become rough and darken a little, it is better to refuse to buy such a coating.

-

The tile should not be too bright and rich in color, as this is evidence of poor-quality workmanship. Such a coating will quickly crack and begin to crumble.

-

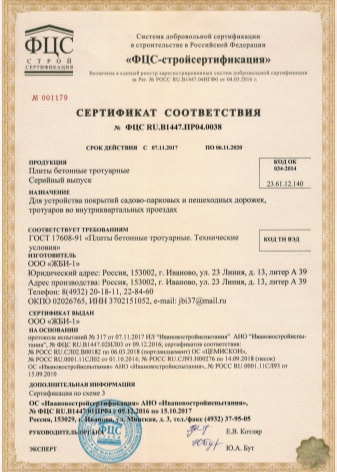

And, of course, in the store you can always ask for a quality certificate for a product.

For to lay the sidewalk area, you should buy a cover in advance with a margin of 10-15%... This is due to the fact that in the process of work you will need to cut the tiles to the required size. And also there is always a chance that some of the material will be defective.

Installation steps

The preparation of the foundation with your own hands includes:

-

removal of the fertile soil layer (approximately 35 cm);

-

cleaning of absolutely all roots of plants and trees;

-

laying pipes for drainage;

-

base ramming.

High-quality pavement laying is impossible without detailed preparation of the base.

For the construction of the foundation, the shade of crushed stone does not play any role, although now there are a whole variety of shades. You need to pay attention to them if the material is used to decorate the site.

In any case, before buying a material, you should carefully read the documents for it.

As soon as the basis for work is prepared, you can proceed to the main stages.

-

Initially, you need to lay a crushed stone pillow. To do this, lay out all the crushed stone on the prepared base. After that, the stones need to be leveled and tamped (the layer thickness should not exceed 18-20 cm). The compaction of the layer must be at least 95%. A vibrating plate, a self-propelled roller or a splitting method will help to tamp the crushed stone base.

-

Now you need to install the curbs (or edging stone). Alternatively, they can be planted on a liquid cement-sand or concrete mortar.

-

After installing the sides, you can start laying the pre-cut tiles on the crushed stone base. A rubber mallet is usually used to level the coating. If the tile does not fit evenly, it will have to be lifted and the base should be re-aligned. In addition, a fishing line is used to lay the tiles evenly. It must be pulled over the desired height of the sidewalk cover. This is done both in the longitudinal and transverse directions.

-

After creating the sidewalk, it must be watered abundantly with water. Once the coating is dry, the joints between the tiles should be filled with fine sand. To do this, use a brush with stiff bristles. At the end of the work, the sidewalk is once again poured with water from the hose to wash off any remaining sand, cement mortar and dirt.

Advice! To prevent water from accumulating on the surface of the tile, it must coincide in height with the upper part of the curb. Better yet, create a slope from the central part to the edges of the track within 0.6-0.8%, with side cuvettes where water will drain. Place the cuvettes 30-35 cm from the end of the curb.

For information on how to lay paving slabs on crushed stone, see the next video.

The comment was sent successfully.