All about the bent profile

It is necessary to know everything about the roll-formed profile, its assortment and production in order to solve a number of practical problems. It is useful to carefully study the GOST curved-welded metal profile. It is also worth paying attention to the cold-formed closed and other welded profile.

What it is?

A folded profile is a type of metal product obtained by profiling blanks by gradually adjusting the geometry of a sheet or strip. The whole process takes place inside the rolls of the roll forming equipment.

A variety of materials are used to make bent profiles. Along with hot rolled or cold rolled alloy steel, these can be:

- aluminum;

- bronze;

- copper and copper-based alloys;

- other non-ferrous metals - zinc and brass.

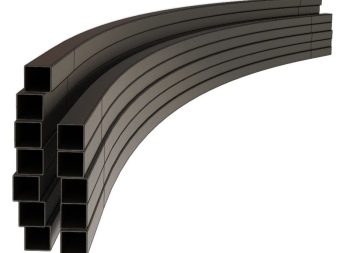

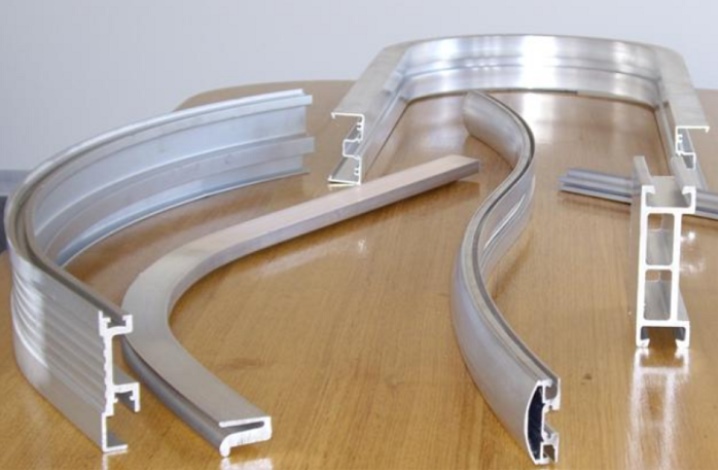

There are many types of bent profile. Some of these products are even originally designed for the construction of railroad cars or are corrugated. The provisions of GOST 30245-2003 are usually applied to the bent profile. More precisely, this standard applies only to a closed category of products, but this fact does not create special problems.

The standard provides for the use of round blanks, which are then turned into square or rectangular products using special equipment.

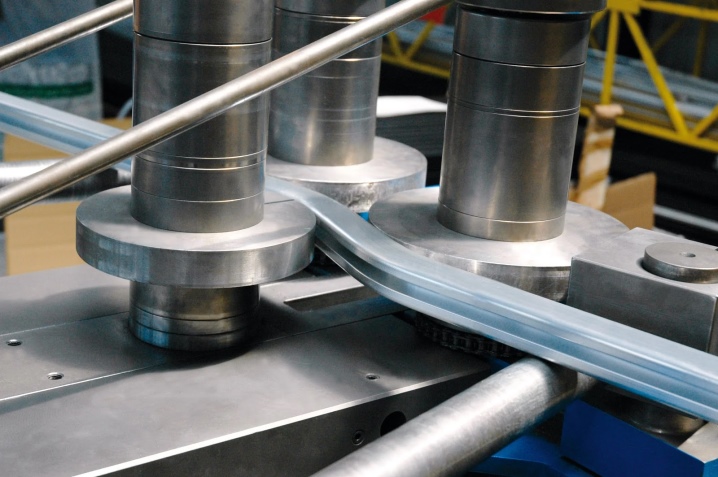

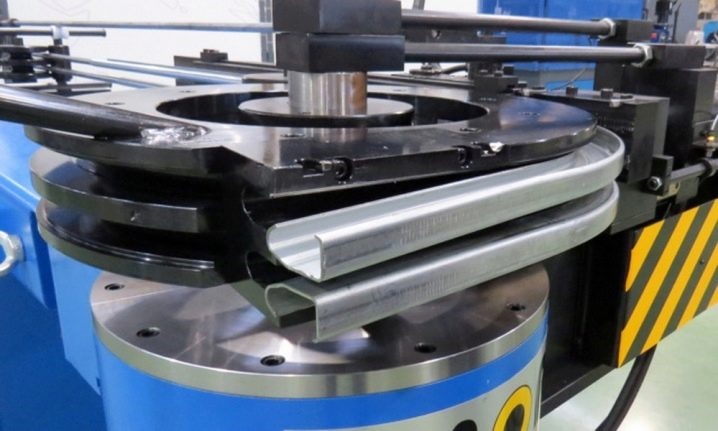

Production technology

Cold-formed bend-welded profiles are produced on so-called roll forming lines. They include:

- straightening machine;

- accumulating rolls device;

- loader of various versions;

- technical reception block;

- stacker (stacking unit);

- production stands;

- cutting system;

- automatic control unit.

In some cases, the line includes a device that cuts the ends of the rolls and connects them using electric welding (arc or point). Metal cutting is performed using special saws or press shears. The roll forming units are marked with a numeric index. The first two of the numbers show the thickness of the workpiece being processed, and the remaining ones show how wide it is; in both cases, the measurement is in millimeters. Roll forming systems work in two main ways.

In one case, the so-called continuous profiling is carried out. The blanks are then cut immediately after shaping. In the piece-by-piece version, the metal is preliminarily cut to the required dimensions and only after that its geometry is changed. The endlessness of the process is supported by welding between the back and front ends of the bales in a chain. Important: If the rolls are not properly calibrated, the quality of the profile is significantly reduced.

Possible violations (deviations from the appearance and geometry of the profiles):

- crescent, that is, horizontal distortion;

- helical;

- the appearance of waves;

- bending of end sections;

- violation of optimal cross-sections at the ends;

- inconsistency of linear dimensions;

- insufficient forming of the rounding radius;

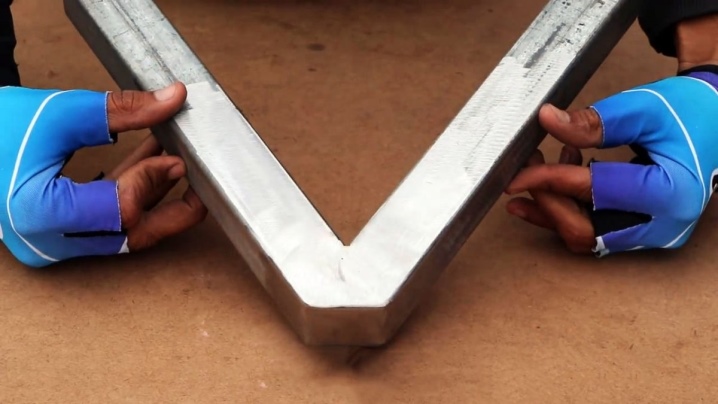

- deviation from a given angle.

The technology of metal profiling was very well developed in the first half of the last century. But this technique is gradually being replaced by intensive deformation technology. Reducing the number of transitions using modern technologies makes it possible to simplify and reduce the cost of equipment equipment. At the same time, the profitability of production increases, this effect is especially pronounced in the small-scale segment.

Materials that are difficult to deform and have low ductility are often processed using the constrained bending method.

But the intense deformation method is more versatile. It allows you to get parts of almost any section. Undoubtedly, all methods will be improved in the future. Their application can vary greatly from manufacturer to manufacturer. Therefore, it is necessary to be interested in the intricacies of processing when placing an order.

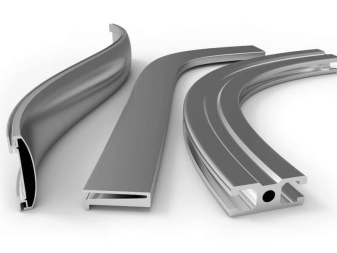

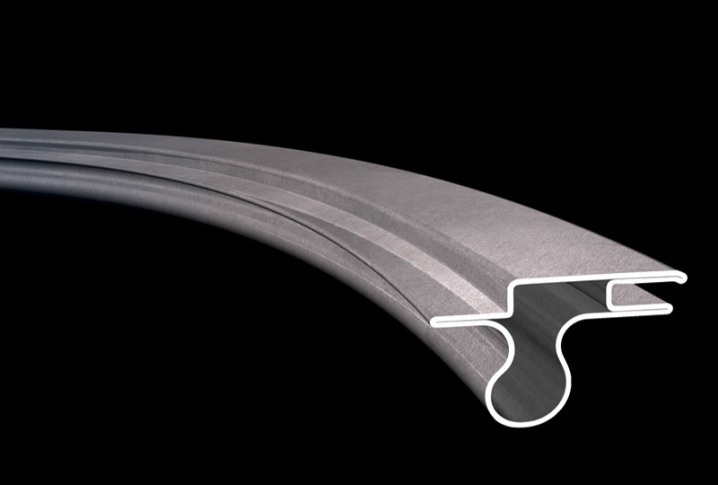

Curved profiles, despite all the particular nuances, are always formed by two main details. It is customary to call a neck an extended flat base. A shelf is called flat edges, bounded by bends on one side. Typical sheet thickness is 1-3 mm. Its length is chosen by the customers themselves; in most cases, a seamless steel roll is used as a blank, which does not have surface irregularities and other visual defects.

Sophisticated galvanizing technology is always subordinated to one task: extending the life of products. In principle, the profile can have any configuration chosen by the customer. Engineers diligently think over where and what holes can be drilled without changing the basic parameters of the structure itself. Modern developers pay a lot of attention to reducing, as much as possible, the metal consumption of manufactured products. The finished profile has all the necessary parameters for outdoor use, including for roofing work.

Views

Corners

Among the assortment of metal profiles of the bent type, the corners of equal and unequal structures occupy a special place. Such products are designed to increase the strength of structures, and therefore are in great demand. Corners are often used when building fences and installing wickets. In some cases, the final stage of treatment is the application of enamel with anti-corrosion properties. The cost of the final product very much depends on which particular alloy it is made of.

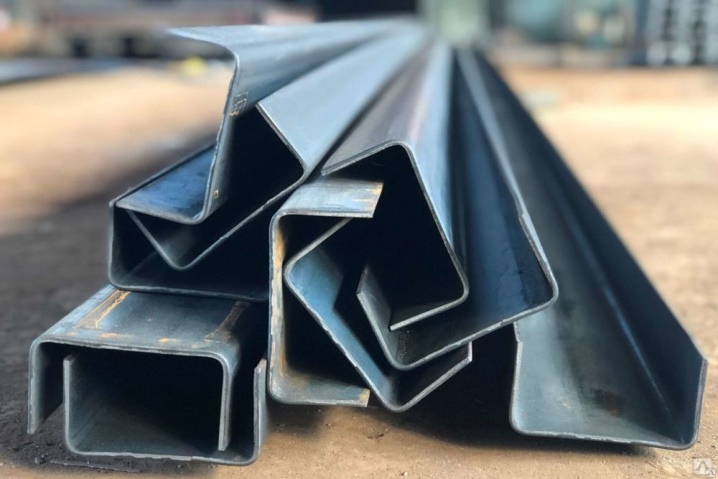

U-shaped

This type of product is also sometimes called bent channels. The thickness of such a product for most manufacturers is 4 or 5 mm. The differences between the models relate to the uniformity of the shelves, the presence or absence of perforation. The scope of application of the U-shaped bent profile is practically unlimited. It is often used in construction, and for the most complex projects, custom-made structures with strictly specified parameters are used.

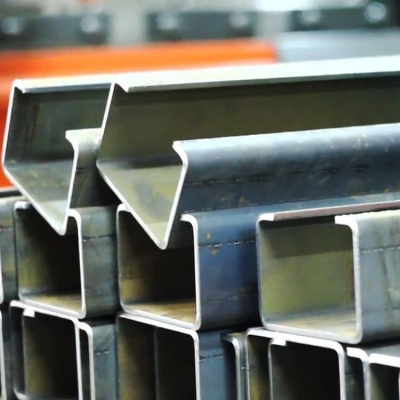

C-shaped

The curved configuration has the most positive effect on the strength of the manufactured product. This makes it possible to somewhat reduce the consumption of metal and thereby reduce the cost of finished structures, make them lighter. Almost any company produces such a product, using each time the dimensions and other parameters at the discretion of the customer. There are also ready-made size ranges of the assortment. For the manufacture of profiles of this shape, calm and semi-calm steel can be used.

C-shaped structures are in demand by both builders and machine builders. Compared with conventional hot-rolled models, a 15-20% reduction in material consumption is achieved. Frequent applications:

- warehouse racks;

- frames of metal walls;

- production of communication masts;

- construction of gates and fences.

Z-shaped

Such models are very widely used by builders. Structurally, it is a strip of metal with a pair of oppositely spaced shelves. There are, as in other cases, equal and unequal options. A number of companies supply products with powder coating in any color specified by the RAL system. Resistance to multiple bends is guaranteed without any loss of strength characteristics.

Channel bars

A closed welded profile can have:

- rectangular;

- square;

- round configuration.

The peculiarity of the bent channel is that the sides of the metal sheet are bent 90 degrees during the production process.The production can use the 1983 and 1987 standards. The choice of a specific standard is, of course, negotiated with the customer. Typical length - 6, as well as 12 m.But users also have access to non-dimensional products ranging from 3 to 11.7 m.

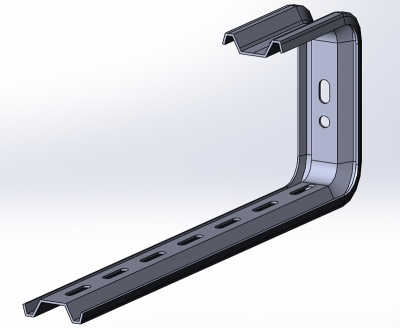

Sigma profiles

This kind of curved profiles got its name for the similarity to the ancient Greek letter. An important feature is the minimum level of load on the underlying elements. This property is appreciated by builders and architects. For the manufacture of a sigma profile, specific machines and steel grades 250-350 are needed. Installation of ready-made elements is very simplified and can be performed even by inexperienced performers without any problems.

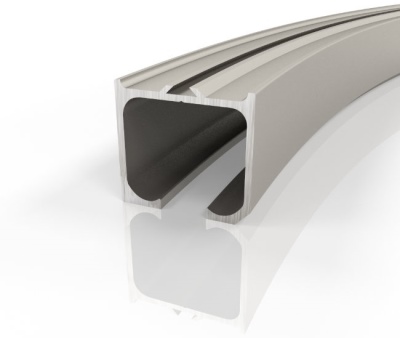

Omega Profiles

Their purpose is the installation of LSU panels. Fastening can be performed both horizontally and vertically equally. Usually the thickness of the metal does not exceed 1 mm. Aluminum is mainly used to obtain the omega profile. In some cases, it is produced from steel. But it is always important that such a product exerts almost no load on the base.

It should be borne in mind that all the options just listed for the profiles can also have an open-ended design.

Applications

As has already been noted many times, the field of use of these products is very wide. They can be bought for the needs of industrial and civil construction. It's about creating:

- carriers;

- enclosing;

- decorative designs of various types.

The bent shaped steel sheet has excellent load-bearing capacity. Its stiffening ribs ensure reliability even under heavy load. Such products are rarely used for the construction of residential buildings, but at industrial facilities they are clearly more common. For example, folded flat sheets are regularly ordered for the construction of large factories and thermal power plants. Another important application is to replace traditional wall panels.

It is worth noting that the curved profile is also in demand in the construction of roofing elements. There, its relative lightness and undoubted strength turn out to be very significant advantages. As for products obtained by the constrained bending method, this approach was first applied in aircraft construction. It is used in this industry in the 21st century.

Also, bent profiles are bought:

- for the formation of floors (floors);

- for the formation of belts and braces of roof trusses;

- for the production of commercial equipment;

- for the production of gas and electric stoves;

- for the needs of food engineering.

The comment was sent successfully.