All About Larsen's Dowel

Sheet piling is considered to be an effective method of protecting an earthen wall from collapse. In the process of creating a pit, the dowels are immersed in the ground and a soil excavation is made. This type of fencing is quite common in areas with limited space and construction sites on loose soil. Quite often, in the fencing of pits, they use the Larsen sheet pile, which has many advantages over other options.

What is it and what is it for?

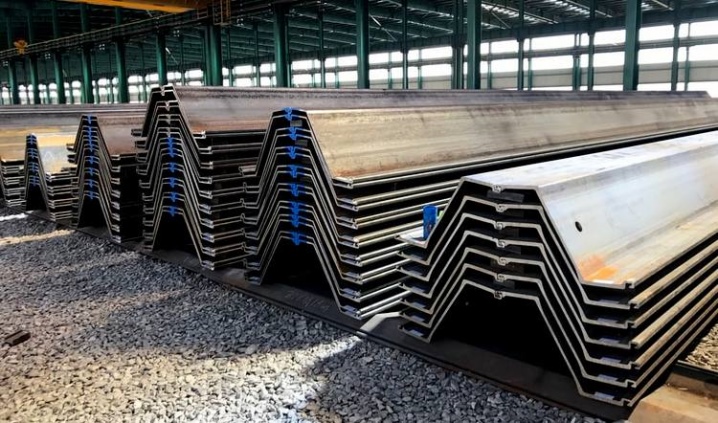

The Larsen tongue and groove looks like a kind of trough with rounded corner elements, which are easily connected into a single structure. Due to its simple design and ease of connection, the tongue works efficiently and is widely popular. To facilitate the connection process, increase the tightness during the production of the structure, sealants with a silicone base are used.

This type of rolled metal is characterized by anti-corrosion resistance, so I use it to work in an aqueous environment. In addition, the Larsen tongue can be used repeatedly. A quality product can withstand 6 times of active use. Upon completion of construction, the fence can be easily dismantled.

The Larsen sheet pile is a hot rolled product. It is made from high carbon steel.

Among the features of the product, the following are distinguished:

- high strength;

- good resistance to oxidation processes;

- multiple use;

- ease of installation;

- the possibility of using on soils of any type.

Applications

The main purpose of the Larsen sheet pile is to strengthen the slopes and prevent shedding, soil creeping. In addition, the design has found its application on construction sites, as an option for limiting flooding. The product is simply irreplaceable for the arrangement of the coastline, piers, embankments.

The Larsen sheet pile is also used to create the following systems:

- plumbing and sewerage at the plant;

- underground communications, as a fortification of a trench;

- dams, bridges;

- road and railways;

- residential buildings;

- oil refining enterprises;

- strengthening the coastline of natural and artificial reservoirs;

- anti-landslide structures.

Types and their characteristics

GOST for Larsen sheet piling indicates the division of these elements into varieties that differ in size, weight, service life. Considering the above points, the technical characteristics of the structures are determined. The most common types are considered.

According to the material of manufacture, the Larsen sheet pile is divided into metal, reinforced concrete, wood, plastic, PVC.

By types of castle:

- Z-shaped;

- S-like;

- L-shaped;

- trough-shaped.

According to the production method, Larsen sheet piles are cold and hot-rolled, made of steel, with good corrosion resistance.

The assortment of this product is sold in a wide variety. Each type of device has its own resistance to loads, which is influenced by how much the sheet pile weighs, its length, shape and metal consumption.

L4

The Larsen L4 tongue and groove has the form of a trough-shaped product, which is connected by tongue-and-groove locks. The mounting width of the product is 0.4 m, the length is from 50 to 220 cm. Often the height of such a profile is 20, 45 cm, in the central part the wall thickness is 1.45 cm, and from the sides - 0.95 cm. 1 m2 of this rolled metal has a weight of 185 kg. The product is characterized by a strength of 518 kN per 1 m of length.

L5

The L5 sheet pile is practically similar to the previous version, however, it has individual characteristics:

- installation width 420 mm;

- length 240 cm;

- the thickness of the main wall is 2.1 cm, and the side wall is 1.1 cm;

- strength - 698 kN / m;

1 m2 of such a device weighs 238 kg, while the height of the profile usually reaches 19.6 cm.

L5-UM

The Larsen sheet pile L5-UM has a carrying capacity of 906 kN / m, while the square meter of such a product weighs 113 kg. The working width of the device is 0.54 m, the length of the product can vary from 50 to 240 cm. The height of the L5-UM profile is 23.6 cm, and the width of its main shelf is 34.4 cm.

Other

Another type of Larsen sheet pile, which is used for the construction of the excavation, is L5D. The height of such a profile is 24 cm, the installation width is 0.51 meters. Weighs 1 m2 of this type of Larsen sheet piling 105 kg.

Manufacturers

Larsen sheet piles are made in Russia and Ukraine, as well as abroad. An example of a domestic manufacturer producing quality goods of this category is Evraz.

Such brands of rolled metal are very popular.

ARCELOR. The manufacturer of Larsen sheet piles is located in Luxembourg. Its factories are located all over the world, including in Russia. The firm produces the following types of profile:

- AZ - Z-shaped products with large width and high load-bearing capacity;

- AS - flat sheet piling, which is often used to enclose cylindrical structures, where it is not possible to install anchor structures;

- U is the standard trough type of Larsen sheet piling.

HSP. This type of sheet piling is produced in Germany. The product is characterized by significant load-bearing capacity as well as good strength. Such devices have found their application during the installation of sewage systems, as well as paths that remove chemical and radioactive particles. The manufacturer sells about 40 models of this category of goods, each of which has different strength indicators.

VL is a sheet pile produced in the Czech Republic. It is characterized by thin profile walls. The rest of the quality characteristics are almost the same as the goods produced in Russia.

Installation steps

The speed of immersion of Larsen sheet piles is influenced by the length of the product, as well as the characteristics of the soil. Profile piles can be installed by pressing, driving and vibrating. The technology for installing the structure is carried out in accordance with the preliminary calculation and design position.

Structural hammering is used outside of urban buildings, since vibration can have a negative effect on residential buildings and nearby structures. Dowel piles are hammered with a copra. This unit has an impact mechanism in its design. Thanks to this, the penetration of the support steel is quick and cheap.

Others, Vibration immersion is considered an equally popular method of installing Larsen sheet piles. This method has found its application in the case when it is not possible to hammer the support wall fixtures. For example, on the coastline, on soft ground and water sources. In this case, the work is carried out using a vibratory driver.

Stages of the procedure:

- fastening the tongue with slings to the vibration mechanism;

- carry out the guidance of the rack in accordance with the design position.

After that, the piles are subjected to great pressure using vibrations, which contribute to the immersion of the products in the soil. During the vibration immersion method, the soils are not subjected to strong pressure.

If we compare this method of installing the tongue and groove with the previous one, then its difference is the high cost.

The most expensive way to sink Larsen's structure into the ground is considered to be indentation.This option is not allowed for use in urban areas. The procedure is carried out with the help of a special unit - a pile-pressing installation on a caterpillar track. The grooves are vertically fixed to the movable mechanism, after which they are immersed in the ground to a certain depth.

Dismantling features

Over time, the supporting walls of the pit may become unusable. In this case, it will be necessary to remove the sheet pile from the soil. Dismantling of the Larsen device is carried out using a vibration device. When using a crane, the procedure will be ineffective, since the soil is characterized by a high friction force, the weakening of which is possible only if short vibration amplitudes are used.

For dismantling, the dowels must be fixed in the vibrating unit, which is suspended from the crane. After that, the generator is connected, increasing the pulling force.

The Larsen sheet pile is currently widely used, as it is considered one of the most stable, safe and reliable options for strengthening the excavation. The high cost of the products is paid off by the high quality of the structures, as well as the possibility of their reusable use.

For more information on what a Larsen sheet pile is, see the video below.

The comment was sent successfully.