Features of aluminum profiles

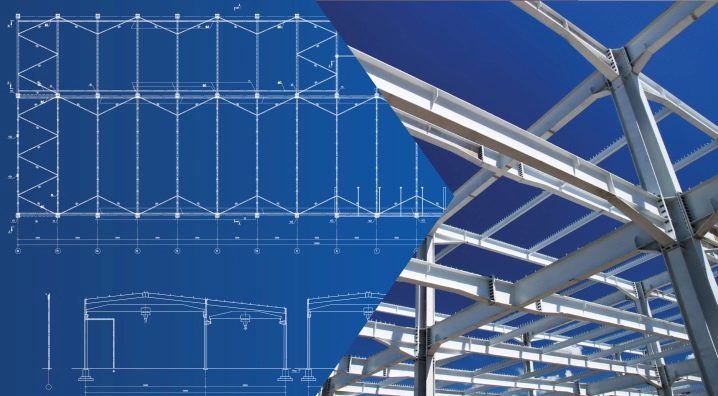

Aluminum profiles are required to create certain building structures. They can be parts of a window frame or facade frame, and such elements are also used during installation work with drywall. The main features of aluminum are its lightness and strength. And we will talk about the main intricacies of working with him in our article.

general description

Many novice builders do not understand what is the peculiarity of the aluminum profile and why it is so in demand on the market. If almost everyone is familiar with aluminum as a metal, then some may have questions about the profile.

A building profile is a structure that has a given sectional shape, as well as certain dimensions.... It is often used in the construction or decoration of something.

Aluminum profiles have the same purpose as building ones. It is noteworthy that preference for metal is given for its durable and modern look. At the same time, the entire structure will be light and mobile, which will allow not only to correctly install the profile, but also to give it the required dimensions and shape.

The material for making a profile is an alloy of different metals. In addition to aluminum, the composition will include magnesium and silicon. Hot extrusion is used as the alloy method, that is, the resulting metal is passed or extruded through the die of the extruder. It is this combination of elements that gives all the necessary characteristics for the comfortable use of this material in work.

The main advantages of an aluminum profile are as follows.

- Long service life and reliability. Indeed, the magnesium in the composition adds more strength to the frame, reinforcing all corners and transitions and thereby preventing the profile from changing under the influence of a certain force. And it is also noted that the structure has increased resistance to corrosion and temperature drops. This is one of the important traits that a material should have, which will be outdoors for a long time and be exposed to moisture, wind, and chemicals. If the profile is used for furniture, then it is still processed using anodizing. This further enhances functional performance and reduces the risk of rapid failure.

- Light weight... Aluminum is a lightweight metal. The lightness and simplicity of the configuration give great opportunities for the use of this material in various voluminous, large and complex structures.

- Security... The profile material is completely clean, without harmful or toxic impurities. When heated or interacting with any substance, it does not emit dangerous toxic fumes. This is especially important if the part will be in the sun for a long time.

- Ease of care, or to be more precise, its complete absence... The aluminum profile does not need any special maintenance procedures to extend its service life.

The only drawback noted by builders is poor quality alloy, that is, during casting, an admixture of another metal or metals was added to increase strength, wear resistance or other characteristics. But the problem is that aluminum cannot interact ineffectively with other elements: after a while, traces of corrosion may appear on the profile.

If this happens, then, unfortunately, this part can no longer be used.

Specifications

All building materials have their own characteristics that must comply with GOST. The data should include detailed dimensions, weight, type and type of production.

All models vary in the degree of configuration, can be simple or complex, and also designed for specific jobs.

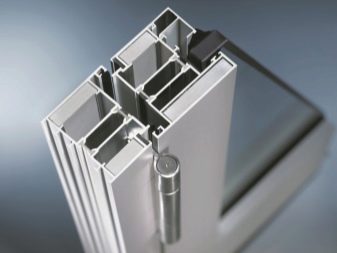

For example, an architectural and construction profile is used for the manufacture of structures for fences or window and door elements. Alloy marking may look like an alphanumeric value (AD31 or AD33). It should also contain a dimensional grid. Usually, the sizes of 20x20, 20x40, 30x30 and 40x40 cm are used for windows. Of course, a lot will come from the requirements for specific models. Designs can be wider or, conversely, narrower.

Aluminum fittings are also used for vehicles. Only the alloy will be used a little differently, and it will have the following marking - the content of one letter and one number, or just a numerical value (for example: A2 or D3).

Universal profiles are used for the manufacture of furniture (for example, office partitions) and can have dimensions of 10x10 or 50x50 cm. Often a universal part has a minimum thickness of 8-9 mm, depending on the manufacturing plant.

Views

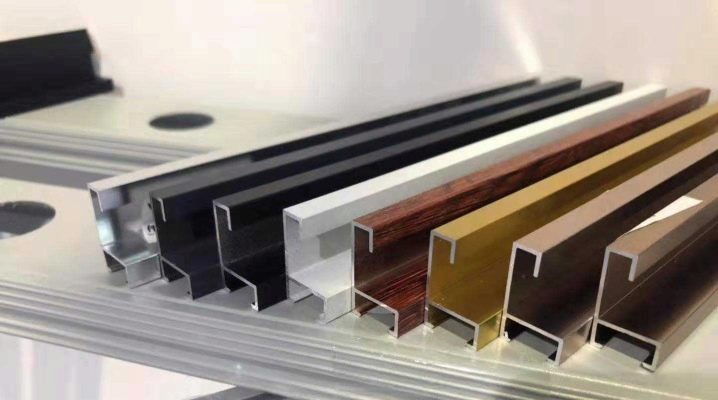

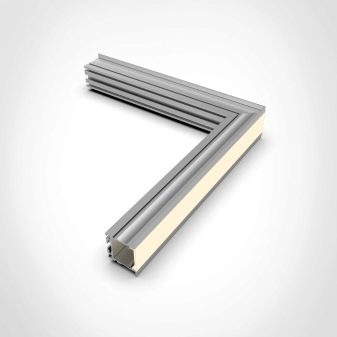

Aluminum profiles are divided into types and differ not only in shape (flat, bent), but also in color (black, white, colored). Each of them can be designed for a specific job. Some detail will be decorative, the other will be connecting. They also differ in the type of installation: the profile can be laid on or cut-in.

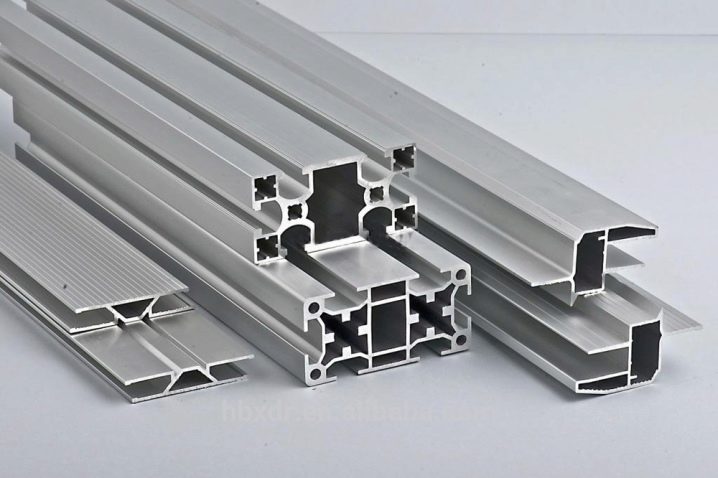

By form

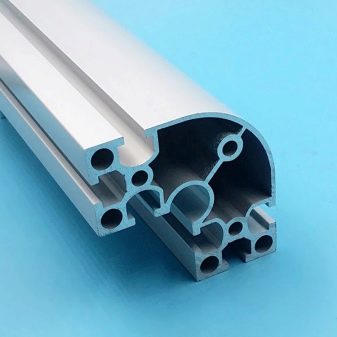

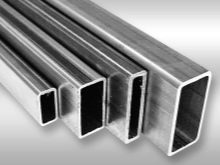

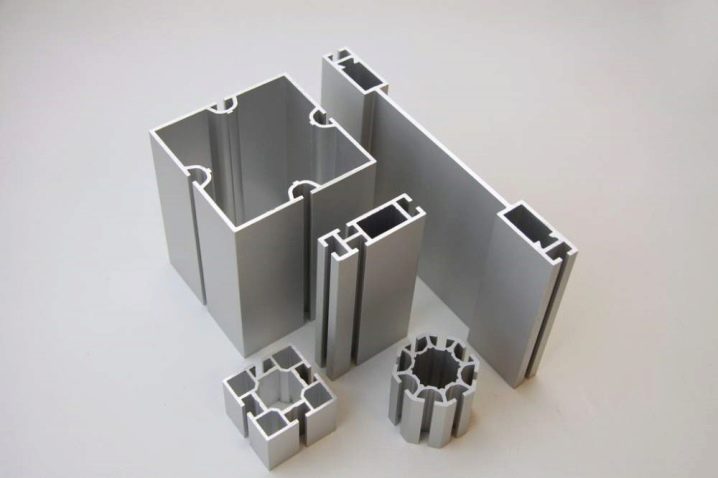

The outer shape is the first sign of how metal profiles differ from each other. Each type has its own purpose and purpose. Let's take a look at some of them.

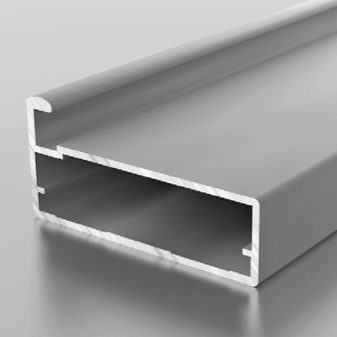

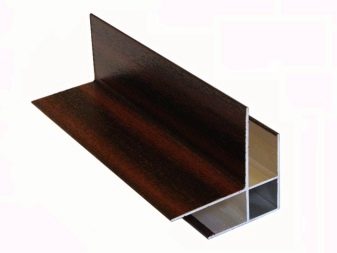

- C-shaped profile. It is used for furniture, or rather, decorative finishing of furniture facades. And also can be applied as a guide.

- H-shaped, or I-beam. It is used to create frames for partitions indoors, less often for furniture lighting.

- F-shaped. Used to assemble and securely fix several elements at the same time.

- H-shaped. It is necessary in order to connect the joints of two sheets, which are on the same level, into one sheet.

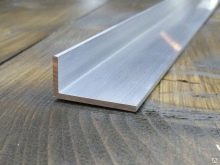

- L-shaped, or corner. It is used as an end edging of a frame or facade.

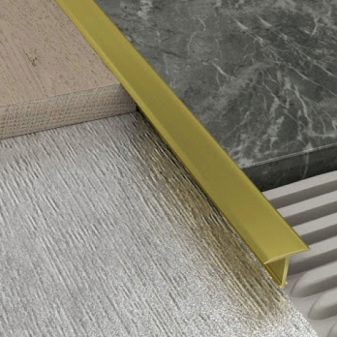

- T-shaped, or brands. Reinforcing structure that is designed for a large or maximum weight of building materials, for example: solid wood or porcelain stoneware. It is also a two-piece connector.

- U-shaped, or channel... Designed for double framing of products: top, bottom and side.

- W-shaped... It is most often used when creating sliding doors, for example, for a wardrobe.

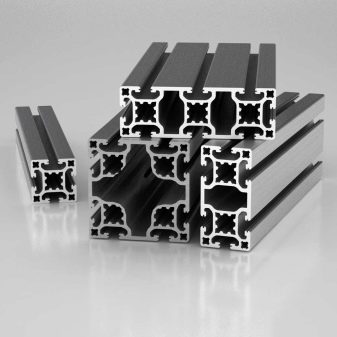

By internal filling

The considered parts differ in filling and have the following configurations.

- Hollow... The profile inside has free space, but there is a closed part on one side.

- Solid... The sides do not have closed sides.

- Free end... The element can be supplied with either a hollow or a solid piece.

By production method

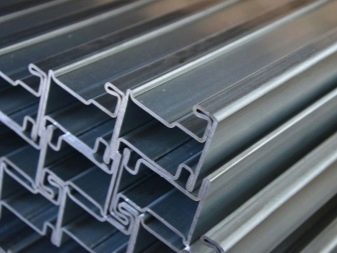

In the manufacture of aluminum profiles, 2 methods are used.

- Cold-formed... This process involves working with thin strips of aluminum that are no more than 4 mm thick. They are bent under the force of the machine in predetermined proportions and directions. Heating elements are not used during operation.

- Pressed... In this case, the heating temperature is already applied, as well as the pressed mechanisms. Under pressure and with the help of high temperatures, the part acquires the necessary parameters and is hardened. The profile can not only be bent, but also aged. There are structures that have been pressed, but have not been heat treated.

By staining method

There are 3 staining methods in total.

- Ready... Powder paint or coating of the required color is applied to the manufactured element.

- Decoding... Here, a coating is used that imitates other textures, for example: marbled profile, wood.

- Anodized... At the time of painting the alloy, a thin oxide film forms on the surface, which is evenly distributed over the entire surface.

By application in installation

Metal products also differ in the way they are installed.

- Connecting... Most often they are used to build greenhouses, gazebos, as well as canopies or arches.

- End... They are used in construction for the installation of structures with specified parameters. A distinctive feature is that the fittings have a special cavity-channel for draining the liquid.

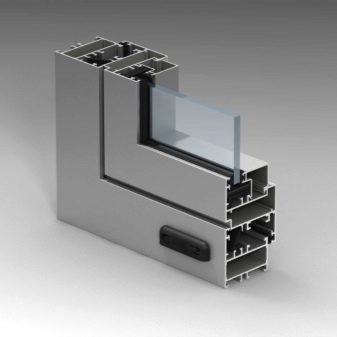

- Click profile used for window frames or light boxes (billboards).

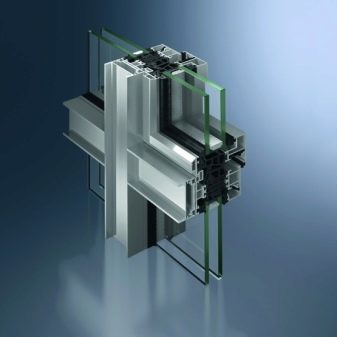

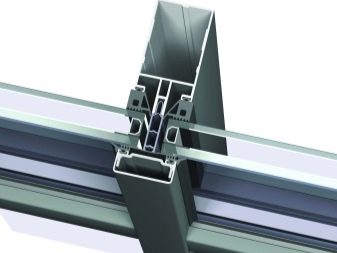

By the level of thermal insulation

Aluminum profiles are marked "Warm" or "cold". This classification distributes what kind of work a particular part is suitable for. For example, warm strips have additional rubber inserts and thermal pads. These panels are used for outdoor work or window frames and doors.

And "cold" elements are most often used in indoor rooms.

Popular manufacturers

There are a large number of manufacturing plants in Russia, as well as entire factories for the production of aluminum profiles. There are independent entrepreneurs in each city, as well as subsidiaries of large world brands.

For example, the Shanghai Bozhun Metal Corporation. It was founded in 2006 and entered the global market in 2015. Delivers its profiles to the territory of Russia through intermediaries.

The Moscow company "IZA-MSK" specializes in the manufacture of parts not only of standard sizes (they have a large catalog), but also according to the customer's drawings.

On the territory of the state, there are other representatives of such large companies as:

- Sapa Building System (Sweden), has a representative office in the Ural-Siberian profile company;

- Finnish company Nordic Aluminum;

- Schuco (Germany).

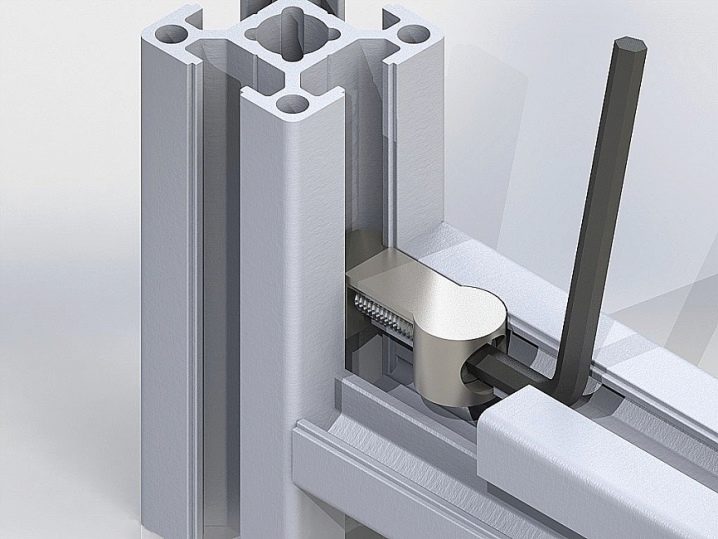

Fittings

Each profile is supplied with or separately with special plugs that cover the frame and prevent foreign objects from getting inside. This is true when carrying out outdoor work. And also there are special additional elements that are necessary during work, for example: t-shaped fasteners, a strip for mounting or a set of hinged hinges.

When ordering directly from representatives, you can assemble all the necessary kit for the installation of a specific structure (for example, a wardrobe). In addition to the profile itself, you can order additional accessories and guides.

What to consider when choosing?

There are several points to follow to select the correct profile.

To begin with, it is worth examining all possible types of fittings in order to accurately assess the variety of products and choose the necessary... At this point, you should read in detail about the shape of the profile section, its parameters and accessories. It is not recommended to modify the purchased profiles, especially if the element will be included in the supporting or supporting structure.

The brand or company also influences the choice. It is best to turn to trusted manufacturers, as small companies can use impurities in the alloy, which affects its quality, but reduces the price.

In consultation with the seller, inquire about the maximum elasticity of the profile, interactions with temperatures, as well as heat resistance and electrical conductivity.

Areas of use

Aluminum profiles are used in many industries. For example, for the manufacture of window frames.

Aluminum corner is used for finishing furniture facades (cabinets or kitchen sets) or equipping sliding systems.

Fittings or strips are used as a frame or guide in construction. Very often, builders use aluminum guides when sheathing houses.Insulation is laid in the resulting niches, and everything is sheathed on top with a board, iron or aluminum plates.

The comment was sent successfully.