All about ceiling profiles

When arranging modern ceilings, ceiling profiles are indispensable. From the material in this article, you will learn what they are, how they look, what they are, what materials they are made of, and also what are the main nuances of their installation.

Description

Ceiling profiles are classified as elements of the fastening system. Visually, these are strips of a given length and width, which have different purposes. They are used to give ceilings a variety of configurations. The main part of the assortment is produced by cold forming. This ensures the rigidity of the frame structures. The stripes have a different cross section. They are used for the design of ceilings in one, two and several tiers.

Together with the ceiling material, they level the surface of the ceiling, mask electrical wiring, communication systems and ventilation. The profiles have different thicknesses, which determines the scope of use.

For example, 0.4mm strips are not the strongest. It is difficult to screw self-tapping screws into them, since they are constantly scrolling. Analogs with a thickness of 0.45 mm are suitable for lightweight frame structures.

Varieties of 0.55 mm are suitable for mounting complex ceiling shapes. They have an increased weight bearing. Like other types, they are used for plasterboard ceilings and stretch fabrics, as well as rack systems, PVC panels. They are easy to handle and offer optimum flexibility. Holes are drilled into them without much difficulty, they are sawn with a grinder. Suitable for creating various types of suspended structures.

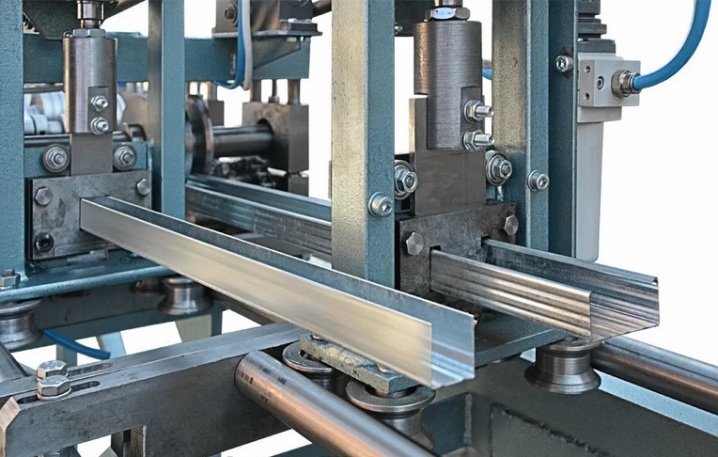

A supporting frame is assembled from the rails. Their typical length is 3 m, but some manufacturers produce products with parameters from 2.5 to 6 m. This simplifies the installation of ceilings in spacious rooms. Some types of products are created on special rolling unwinding machines with a brake system. In the course of production, the belts are unwound and fed for hire. In the course of feeding, they are perforated, due to a variety of rollers, the relief changes.

Shirring increases the rigidity of the planks. At the exit, they are cut to a standard length at an angle of 90 degrees.

Views

Today, the construction market offers several basic types of ceiling profiles that allow you to implement different design ideas when arranging ceilings. Each type of planks has its own characteristics, differences and purpose. It has its own acronym and purpose.

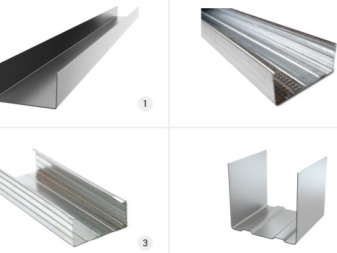

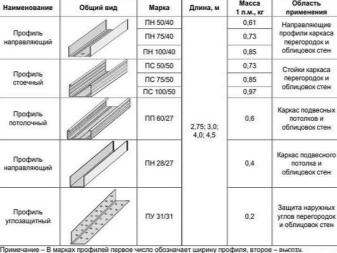

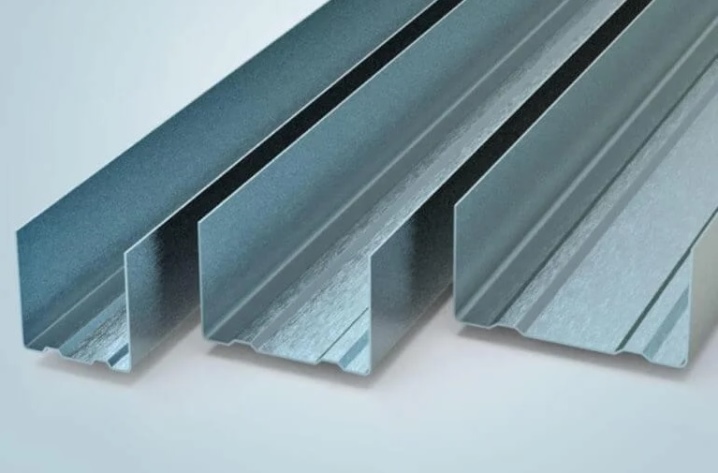

PP

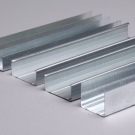

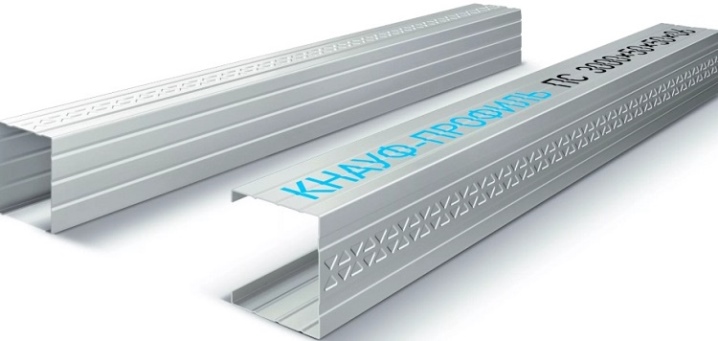

The ceiling CD-profile has a structure visually similar to its rack-mount counterpart. Has slightly inwardly bent ends and extruded longitudinal grooves on the base. Has increased durability.

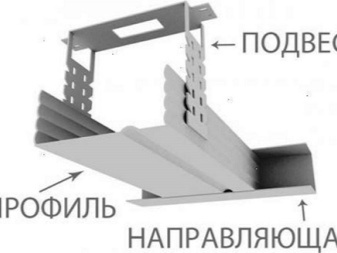

It takes the main load from the entire structure. Fastened with special suspensions. It is marked with a PP 60x27 mark, which stands for "ceiling profile of 27x60 mm in size". It is used in the arrangement of suspended structures with a different number of levels.

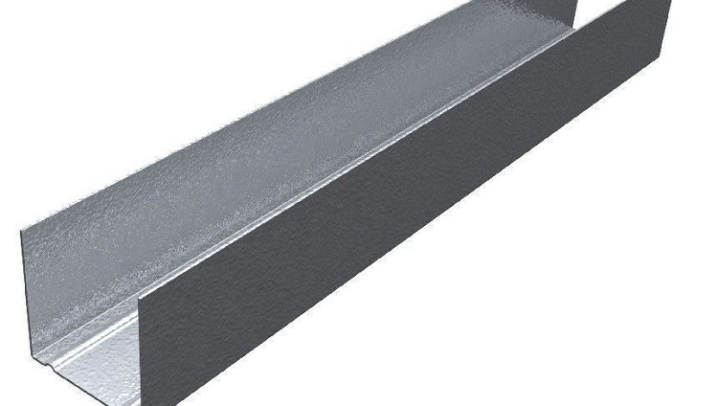

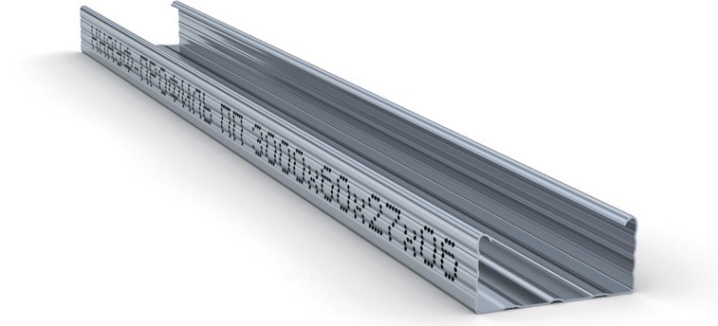

PPN

The structure of the carrier rail on the ceiling resembles the previous analogue. It also has a U-shape, but the dimensions of the width and height are 27x28 mm. Accordingly, it is marked as PNP 27x28. This guide profile is used in conjunction with the previous one. It sets the direction for installation. In addition to the main size, its parameters can be 17x50 and 20x20 mm.

It is sometimes referred to as PS, which does not affect the functionality in any way. It is often used to create lightweight ceiling structures. It can be referred to as UD, it assumes fixation along the perimeter of the ceiling. Depending on the type of execution, it can be classic and perforated.

Products of the second type are more convenient to work with, since they eliminate the need to drill holes for fasteners.

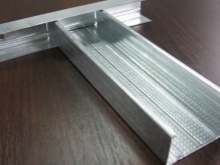

MON

The UW plank is used when arranging multi-level structures. It can be used for a two-level, three-level ceiling, constructing the frame of the lower tiers. It is 4 cm high and is used as a rail for a post profile. Available in classic and extended widths. The width can be 5, 7.5 and 10 cm.

It is used together with slats of appropriate dimensions. Purchased to insert a rack or other guide profile. Looks the same as the rest of the varieties. For stiffening along the walls, it is equipped with longitudinal corrugations. Has 8 mm holes for fixing to the supporting base.

Arched

The difference between such a rail from other analogs is the division into small sections that can be bent in a given direction. It bends not only inward but outward as well. Refers to fittings that provide reliable and tight fastening of the gypsum board. Has a wide range of possibilities. Fixed on hangers. These varieties are produced for frames of curved shapes. They are made from PN-products, supplemented with special notches. Thanks to them, during the construction of the frame, you can change the curvature.

Arched slats are in special consumer demand. They help solve complex design problems. These are perforated strips, also used for plastering. They perfectly hold a constant load. They help create a wave effect and are used in designs with rounded corners. They have a width of 6 cm, a length of 3 or 4 m, and a height of 2.7 cm.The minimum radius of the plank is 50 cm.

Materials (edit)

Ceiling profiles are made of metal and wood (timber). The assembly cold-rolled type is made from strip (strip-type steel) with a thickness of 0.4 mm. It is unalloyed and low-carbon and has a galvanized finish to withstand corrosive environments. Metal profiles are durable, but they are prone to rusting in places where the protective layer is chipped.

Steel slats are inert to insects, do not change their geometry, unlike timber, which swells due to moisture and dampness. The aluminum metal profile is durable and easy to use. The lumber profile is more expensive and environmentally friendly. It is not as strong or durable as its metal counterpart. It implies the obligatory treatment with an antiseptic, anti-flammable composition.

Manufacturers overview

Among the wide range of manufacturers supplying profiles for ceilings to our market, it is worth noting several brands whose products are in demand among domestic buyers.

- Kraf synergy - a Russian brand supplying to the construction market ceiling profiles for gypsum board made of metal (including guides). Produces products of high quality and durability.

- "Proff-STEEL" - a domestic enterprise of the Krasnodar Territory, founded in 2007, annually increases production volumes, offering 4 types of slats for ceilings together with guides.

- PRIMET-M - a trade mark from Novoshakhtinsk. Produces different types of profiles for gypsum boards, complete with elements of hinged systems. Delivers products with an acceptable price-performance ratio.

- Knauf Is a German company, a leader in its segment. Produces profiles with a special pattern on the bases and a company logo. It supplies profiles for suspended and acoustic ceilings to our market.

- EuroKraab - manufacturer of slats with a shadow type of gap, which are used when arranging soaring and contour ceilings. Available in anodized aluminum recessed ceiling strips in various widths.

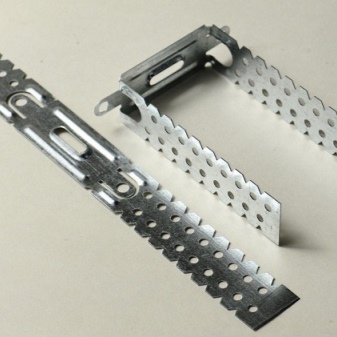

Ancillary fasteners

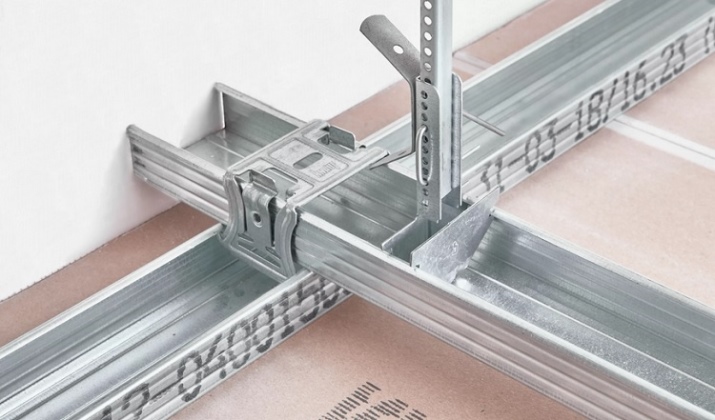

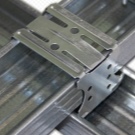

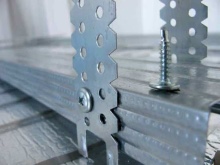

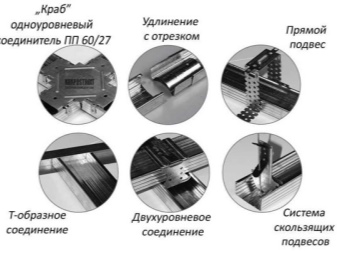

When installing ceiling structures, different types of components are used. Suspensions and connectors are used to connect the profiles to each other and attach them to the floor.

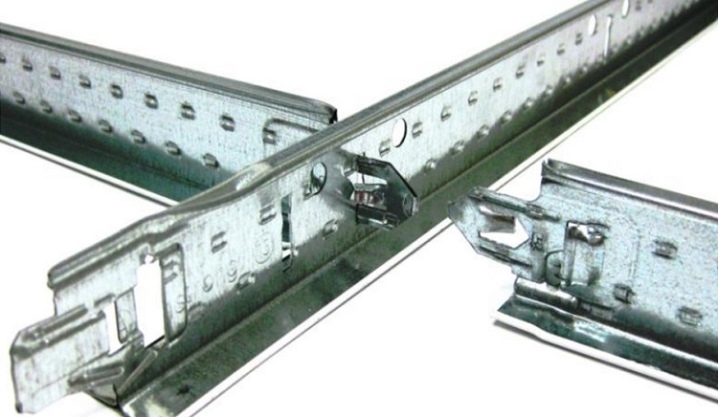

- Suspension - steel bracket with the same width as the profile. It has many paired holes at the same pitch. Suspensions are longitudinal, angular, T-shaped, specialized for cross-connection. Depending on the type of installation, a single-level, double-level connector may be required.

- Fasteners - anchor bolts or self-tapping screws. The first connectors are used when mounting profiles to concrete bases, the second to wooden ones. The strips are connected to each other by piercing self-tapping screws and drilling self-tapping screws.

How to choose?

There are a number of factors to consider when purchasing ceiling profiles. It is important to purchase the product from a trusted supplier. Handicraft products often have visible defects. The profile must have sufficient thickness. If it is not sustained, the whole frame system suffers. In this case, during operation, individual sections will fail very quickly. It is difficult to attach self-tapping screws to such strips. The purchased item should not be suspiciously cheap.

During visual inspection, pay attention to the quality of the coating. Rusty slats are not suitable for installation at all. It will not be possible to remove corrosion, it will spread further, spoil the cladding. You cannot buy profiles for installing a frame with a broken configuration.

Poorly rolled material will prevent the frame from leveling. Even if the supplier is verified, the reason for this defect may be in improper storage of the rails in the warehouse.

Profile parameters must correspond to typical dimensions. With a clearly noticeable change in size, it will not be possible to make a perfect frame. Looking closely at the specific type of laths, they pay attention to the sufficiency of the depth of the incisions applied. When the rail is practically smooth, this defect will make it difficult to screw in the screws.

An unpleasant moment is the presence of burrs. You should not take a low-quality product, complicate your work with additional grinding, it is better to contact another store where you can pick up better quality products.

Installation features

Before installing the frame on the ceiling, preparatory work is performed. It is necessary to calculate the consumption of material, select the appropriate tools for installation, fasteners. It is necessary to correctly calculate the distance between the profiles, depending on the type of frame. They also take into account the number of levels, the type of fastening (along the perimeter, center). After planning and calculations, installation is started.

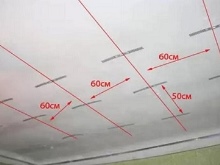

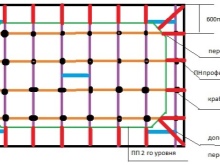

To make the ceiling according to all the rules, the base under the frame is cleaned from the remnants of the previous cladding. Dismantle the chandelier and other hanging elements. Get rid of dust, dirt, fungus. With the help of putty, gaps and cracks are sealed. The overlap is primed and treated with an antiseptic composition. The further type of work depends on the type of frame. For a cellular system measuring 60x60 cm, a marking is created and a guide rail is mounted along the line on the wall. Prior to that, a seal is glued to the side adjacent to the wall, holes for dowels are drilled in increments of 0.3-0.4 m.

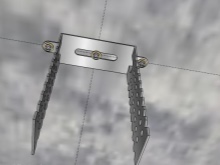

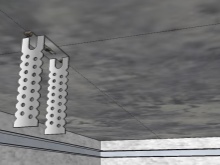

Carry out the installation of guides around the perimeter of the room. Corner connectors are used to connect them together. After that, you can screw on the suspensions. For this, 0.3 m recede from the wall and suspensions are installed along the lines marked for the profiles. Further, the suspensions are screwed in at 0.6 m intervals, mounting them so that each connector is located strictly in the center between the jumper rails.

The side faces of the suspensions are bent down. Then the strips are prepared. Measure out the specified size, and from this value cut off 0.5 cm. This is necessary to prevent deformation due to expansion. The profiles are inserted into the guides, fixed with closures with suspensions.In the course of work, check the horizontal position using a laser level. After the installation of the main PCBs, the “crab” -type jumpers are fastened onto which the rest of the profiles are mounted.

When installing the crossframe, fewer rails and connectors are used. They are mounted in increments of 0.4-0.5 m. After marking the lines for the guides, they beat off the installation locations of the strips. Then the right angle is determined. Holes are drilled in the wall for the guide profile at intervals of 0.3-0.4 m. They take the rail, paste over with sealing tape, and attach it to the wall. After that, the suspensions are installed, bending their ends down.

Profiles are cut, remembering to cut off 0.5 cm in order to prevent damage and warping of the drywall. The strips are pasted over from below with a sealant, then inserted into the guides and fixed with suspensions by means of self-tapping screws (klopps). Complex multi-level structures are made according to individual schemes.

First of all, here you need a complete transfer of the drawing to the ceiling. The complexity will be much higher than with the arrangement of simple single-level systems.

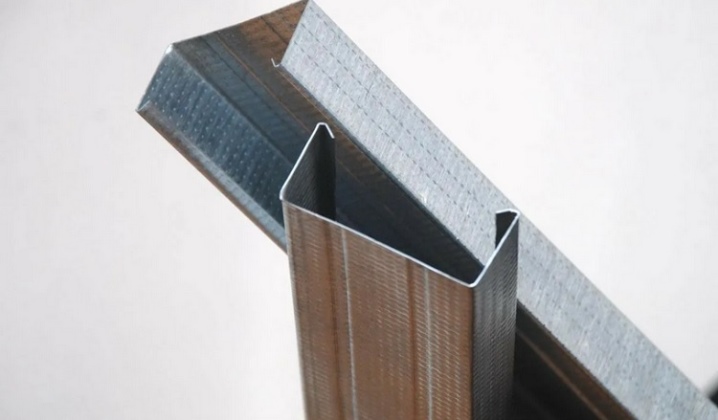

First, you will have to attach all the guides of the upper level, install the hangers with a smaller step. The reduction in the distance is due to the increased load on the floor. Then they are engaged in the installation of top-level profiles. The structure can be cellular or transverse. Next, the guides of the lower level are mounted. One straight rail is cut into vertical posts that act as boards between two levels.

Using special connectors, the racks are attached to the upper level frame. Arched profiles are attached to the bottom of the racks. If necessary, they can be lengthened using an extension with a galvanized steel rail extension. PP is fixed between the arched bar and the guide of the lower level. After creating the frame, proceed to the installation of the ceiling cladding.

The comment was sent successfully.