What is anodized aluminum profile and what is it for?

The article describes what an anodized aluminum profile is. It is indicated what anodizing is and how this technological manipulation is performed. Additionally, information is provided on how anodized products are used, where they are in demand.

What it is?

Anyone who has studied chemistry well in school may remember that aluminum is naturally coated with a thin film. It appears when the metal comes into contact with oxygen, which means that there is no way to avoid its appearance. Sometimes special efforts are being made to temporarily rid metal products of this film, for example, before welding. However, experts have noticed that such a layer, along with negative ones, also carries certain positive properties. As a result of their research, it was possible to create such a product as anodized aluminum profile.

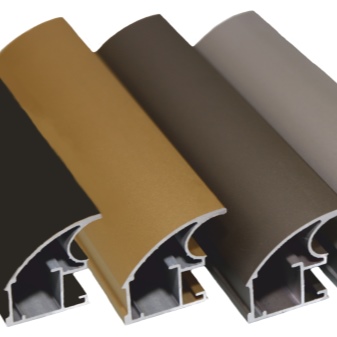

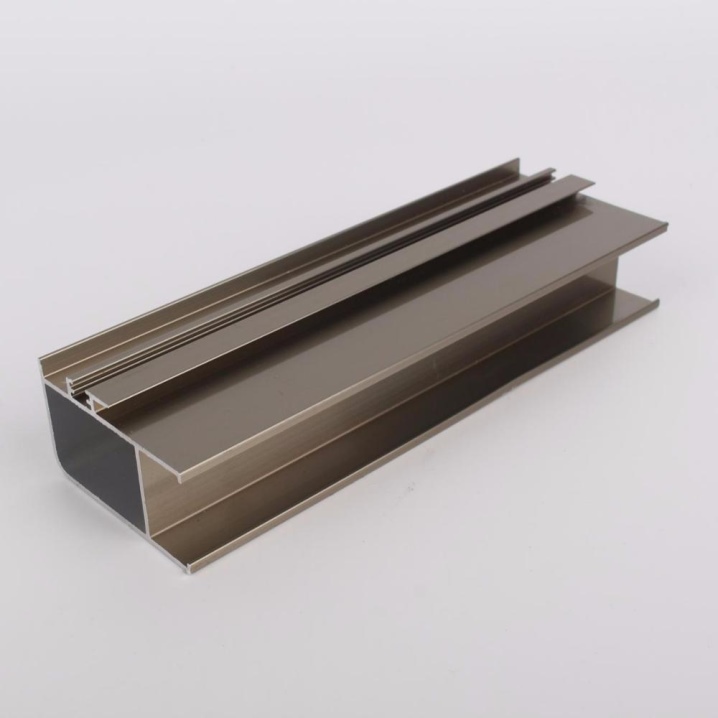

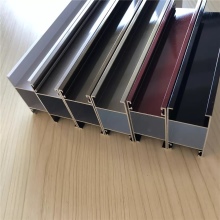

The surface coating is harder than pure metal and even most of its alloys used in everyday life. The level of wear resistance is also higher. Another important advantage is the ease of use of organic-based dyes, because the film contains many pores. This circumstance is important for those built-in and individual products that are designed to have an increased decorative effect. The process of applying the film itself involves the use of electrochemical processes (but more on that later).

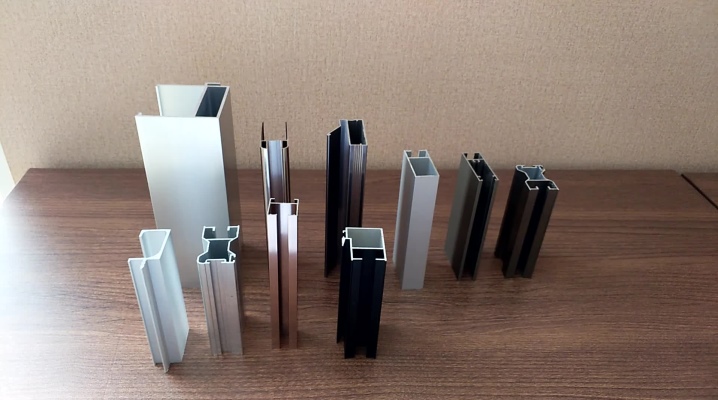

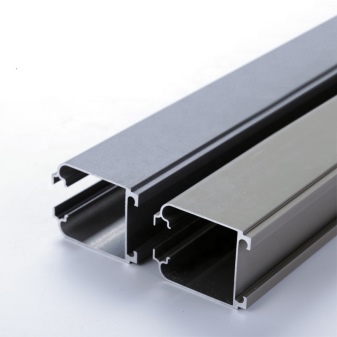

In many cases, the structural anodized profile has a natural silver finish or a sophisticated black finish - which makes it possible to almost always determine the fact of anodizing. After such processing, the material becomes much more durable and chemically stable. Experts also note that its use is safer than using traditional alloys without additional coating.

It has been found that anodized profile is easier to maintain clean and tidy. It perfectly resists even the effects of high humidity and other adverse factors.

Production technology

The very name "anodizing" is due to the fact that in the working process the part covered with a special film turns out to be the anode. The overwhelming majority of technologists choose to use dilute sulfuric acid as the main medium. Its saturation degree can reach 20%. The use of direct current is also usually implied. Its strength should be from 1 to 2.5 A per 1 dm2, while when using alternating current, a force of 3 A per 1 dm2 is needed.

The standard working temperature reaches 20-22 degrees. Deviation from it must be motivated by special considerations. In a special electroplating bath, anodes (yes, they are usually processed at once in a large number to speed up and simplify the process) can be fixed or suspended. Appliances with opposite electrical charges are usually lead plates, although in some cases reagent grade aluminum plates are used.

Important: the surface area of the workpiece and the surface area of the work attachment must match, otherwise you cannot count on a good effect.

It is possible to reduce the electrolyte layer separating the main tools and workpieces only up to a certain limit, otherwise the quality of work decreases. It should be understood that the fixation points of the workpieces cannot be covered with a protective layer.This point should be negotiated in advance. Pendants or clamps cannot be removed, they will remain so until the end of the process.

The anodizing time is directly related to the dimensions of the parts. Sometimes they can be covered with a protective film in 15 minutes. Larger items often take up to 60 minutes to process. When the workpieces are taken out, they are washed under running water. Additionally, chemical neutralization is carried out in a special bath with the help of ammonia, and then another rinsing is needed; sometimes auxiliary finishing is carried out.

Other electrolytes can be used along with sulfuric acid. The basic technological principles do not differ, the changes concern only:

- characteristics of the supplied current;

- the duration of the process;

- general coating properties.

Processing is carried out in the environment:

- oxalic acid;

- orthophosphoric;

- chrome;

- combined organic electrolyte.

Scope of application

The most important task that is solved when anodizing an aluminum profile is to increase its resistance to adverse environmental influences. Therefore, such products are in demand in many areas and are often used as:

- decorative elements in buildings and structures;

- road signs;

- advertising structures;

- informative stands;

- bicycle frames;

- railings;

- searchlights;

- handrails;

- marching stairs and stepladders;

- armchairs;

- knitting needles;

- parts of cars and vehicles;

- heating reflectors;

- pistons;

- frames for partitions and screens.

The comment was sent successfully.