End profile: dimensions and installation

The end profile is used quite often. Customers definitely need to know how to drill a profile for cellular polycarbonate. It is also important to study the information regarding its dimensions and basic installation methods.

What it is?

The end profile is used if it is necessary to prevent the influence of negative natural factors on the edges of the structure. Another function of such an element is to increase the overall rigidity of the assembly. Protection is needed only for cellular polycarbonate. When using monolithic polycarbonate boards, it is optional. If there is no such protection, then the negative impact can be exerted by:

- melt water;

- rain runoff;

- dust;

- garbage other than dust.

Also, honeycomb cavities, being unprotected, are able to attract various insects. Those settle there and can spoil the material. And the appearance will suffer. Soon, polycarbonate degrades, and therefore customers will only have a sharply unfavorable impression.

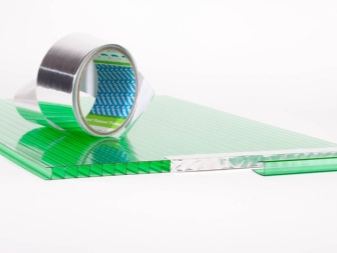

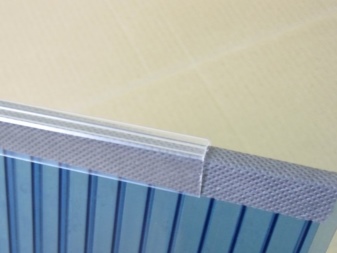

You will have to put on the end profile exactly on the edge of the surface. Such a covering should completely cover the honeycomb. To ensure increased sealing, special flexible tapes are additionally used.

You can buy such devices in the same place as the profile itself. A perforated tape is also mounted on the underside of the sheets.

Types and sizes

The end profile for cellular polycarbonate can be made of plastic or aluminum. This is a bar that bends like the letter P. One edge of such a product is longer than the other. On sale you can find profile structures up to 2.1 m long. The usual cross-section is from 1.5 to 3 mm.

In favor of plastic solutions, they say:

- ease;

- flexibility;

- comparative mechanical strength;

- optimal operational reliability;

- convenience and ease of installation.

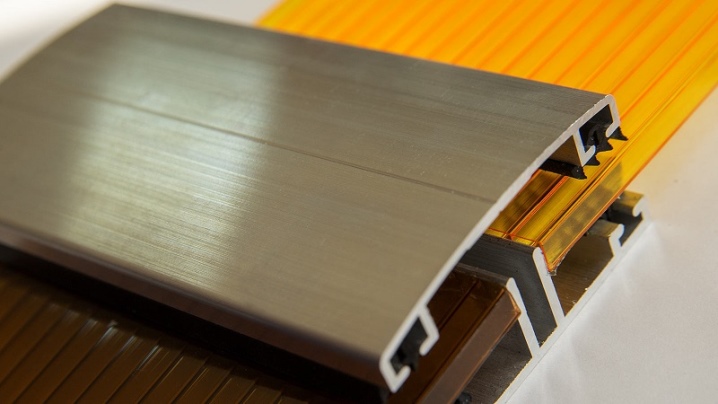

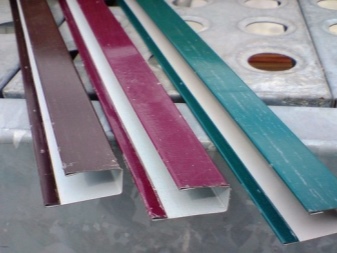

An aluminum profile is significantly more expensive than a plastic one. But it serves for a relatively long time - at least 10 years under normal conditions. Basically, aluminum profile is used to protect thick polycarbonate. But you can easily use this product to work with a relatively thin sheet. Typical, as in the previous case, the letter P.

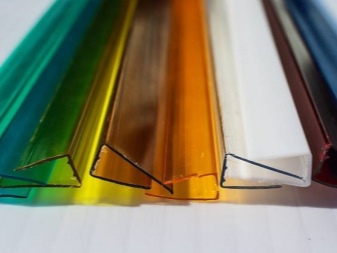

In some cases, not aluminum or a standard polymer is used, but transparent plastic, which looks much more aesthetically pleasing than the usual version. You can easily pick up options with other colors. A very important property is the linear dimensions of the profile. Its thickness exactly matches the dimensions of the most common polycarbonate grades, making up:

- 4 mm;

- 6 mm;

- 8 mm;

- 10 mm;

- 16 mm.

Where is it used?

Do not think that the end plate is needed only for polycarbonate. This product is also useful for working with other materials. The main goal is to protect the space under the roof from the ingress of foreign objects and any debris. In this case, the end profile can be used for both metal tiles and corrugated board. Such structures are made from durable steel grades.

As in the case of polycarbonate, the thickness of the expansion elements must correspond to the thickness of the base material.

Installation methods

Often in different sources you can read that the end profile is worn last. For this, pre-left gaps are used. It is believed that such an installation, due to a narrow edge having an acute angle to the plane of the profile itself, guarantees the most firm pressure on the sheet. It is best to orient such an edge outward. The widened edge is brought under the sheet exactly in the interval from polycarbonate to cladding.

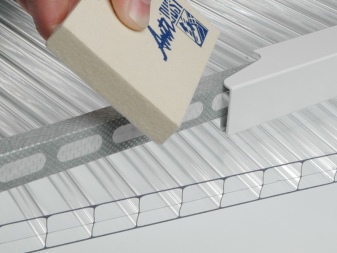

The next step is to apply a spatula. One of its corners is gently inserted inside and gently pry on the still free part of the narrow edge. It is slightly folded back. Next, you need to press on the polycarbonate sheet. This work is carried out in several areas in succession.

When using a docking non-separable profile, it must be borne in mind that these are two end devices connected to each other. Working with it is the same as described above. The spatula again helps to simplify installation. There are also detachable connecting elements. They are twice as expensive, but simplify installation several times.

In some cases, for the installation of the profile, polycarbonate must be drilled. Such work is successfully performed with the simplest electric drills or screwdrivers. The drilling itself is carried out with standard drills for metal. It is necessary to pierce the sheets strictly between the stiffeners, without falling on them, in order to avoid problems.

The distance from the edge of the sheet should be at least 40 mm, the angle of entry of the drill - from 90 to 118 degrees; working speed - maximum 40 revolutions of the drill per minute, so that the polycarbonate does not melt.

The comment was sent successfully.