PVC T-profiles

Plastic brands are in high consumer demand. From the material in this article, you will learn how they look, what they are, how they are mounted, depending on the different types of fasteners.

general description

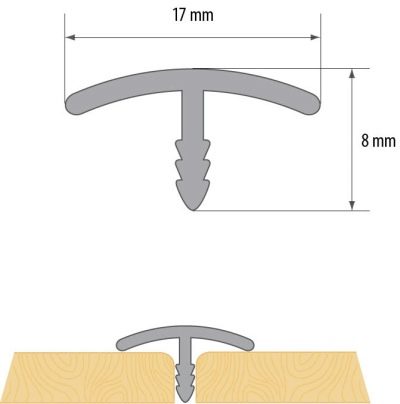

T-shaped PVC profile - a plastic strip of various sizes and shapes with a transverse post. It is called a docking, connecting profile for framing the ends or decorative edging.

The key difference between these products is the T-shaped section type. PVC edging is made for a specific board thickness. It does not provide for trimming excess width.

The most popular options for the width of the visible part are 16, 18, 32 mm. The height of the stand together with the front plate is 10 and 14 mm. The shape of the so-called shelf is straight and convex. The shape of the stand is in the form of a thin strip and with an arrow at the end.

The rack is always located strictly in the center. The plastic profile itself belongs to the basic universal elements that complete the repair. It is moderately flexible, inert to the formation of fungus and mold.

With its help, sheet building materials (drywall, chipboard, MDF, plastic panels) are joined and edged. It is used in furniture manufacturing for furniture joints, used for decoration of ceiling structures.

Advantages and disadvantages

The T-shaped plastic profile has a number of advantages. It is practical and aesthetically pleasing. It harmoniously fits into the interior of any design style.

Easy to install on different types of surfaces. Has a wide range of colors and textures. Can be mounted linearly and curved. It has an optimal thickness, it is firmly held on the base.

Available on sale in a wide range, so everyone can choose the option they want, taking into account their own taste preferences. Harmless to the environment and human health.

It differs in the degree of rigidity and varies in size range. Looks harmoniously in rooms of different styles and sizes. Suitable for joining the same and different building materials.

Fastened firmly and reliably, looks beautiful and appropriate. It can be matte, glossy, structural, and can have a reflective surface. Perfectly hides chips and defects of the butt-ends of the materials being joined.

It has a length of 3 and 6 m, due to which it allows you to do without extending the length. It has a wide price range and is designed for a buyer with different financial capabilities.

Along with the merits, the plastic brand has several disadvantages. The key one is gradual vulnerability to mechanical stress. With strong impact, scratches and chips remain on the surface.

It is also bad that over time the edging loses its original aesthetics. Some varieties are not able to reliably protect the ends from moisture, debris, dust.

Views

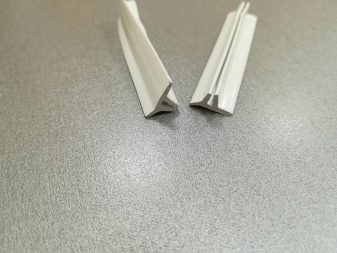

A T-profile made of plastic is classified according to various criteria. By the type of execution, it can be classic without a girth and with a girth.

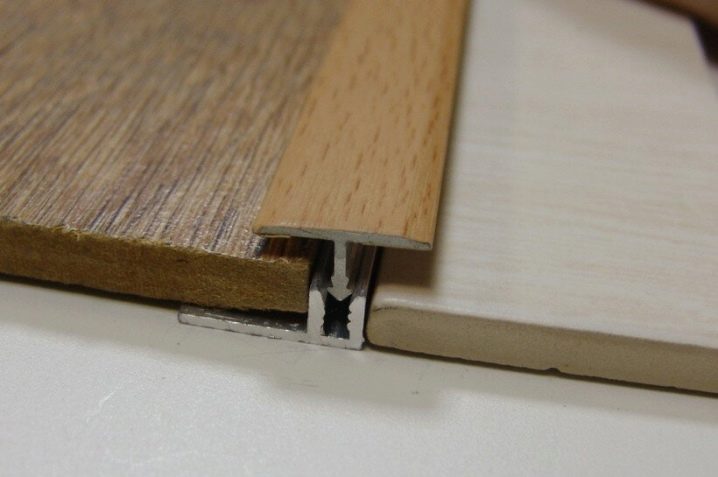

Variants of the first type in cross-section resemble the letter "T" or a mushroom. Their shelf is flat, rounded, the side ends do not have bends. The rack width is universal.

Analogs with a girth are distinguished by curved side edges. Such a profile has a different fastening, it reliably presses the butt end and is used as a finishing edge.

Depending on the level of flexibility, plastic brands are hard and soft.Moreover, most often for edging curvilinear and radius structures, a girth option is used.

Such modifications can have different antenna lengths. The best brands are those with larger girths. In this case, the rigidity of the cutting edges should be greater.

Soft analogs are problematic to work with. During driving into the groove, their legs often break and bend.

During operation, they bend, which leads to the ingress of debris and the opening of existing edge defects.

Profile colors can be neutral or colored. Standard varieties are white, black, gray, brown. The colored finishing profile often imitates the texture of wood.

Laminated plastic brands can have a shade of dark chestnut, grayish, bourbon, Scandinavian oak. On sale there are varieties for aluminum, ash, pine, caramel.

Shades are rich, pale, light, texture - with dark and longitudinal wood fibers. Neutral brands do not have color splashes.

Lamination options are referred to as decorative edging. Therefore, this line has a lot of varieties of tones of different saturation, temperature and color. Thanks to this, the buyer can select the profile as accurately as possible to match the color of the interior.

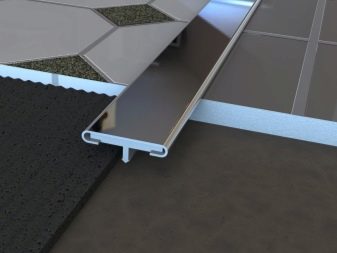

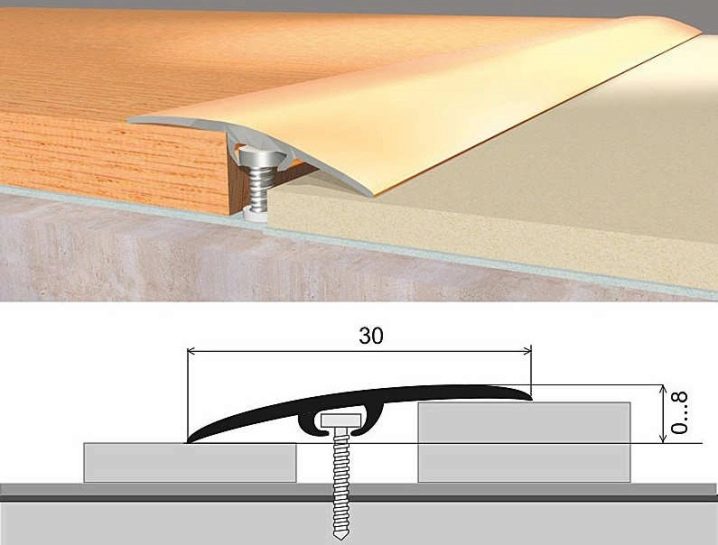

The floor profiles are in two parts. This equipment simplifies the installation of the planks on the floor cladding. In this case, the lower part is attached directly under the cover.

The upper one snaps into the groove of the lower bar. In this case, the height of the profile itself is associated with the mounting plate. Therefore, it can vary between 7-24 mm.

The type of mounting brackets varies. The floor brands themselves have a standard width and a slightly protruding top panel. These varieties are good in that, as needed, they can be easily dismantled and replaced with others.

This is convenient when the plastic profile has lost its former attractiveness or is chipped. Such profiles do not have lateral tendrils, the edges are slightly rounded in order to make the use of the floor as safe as possible.

How is it installed?

The T-type docking finishing profile is mounted on glue or a special mounting plate. In the first case, the simplest varieties are used, planting them on liquid nails.

For him, the type of planks with a narrow stand without notches is suitable. To fix the profile, it is enough to pour the required amount of glue into the opening between the mating materials.

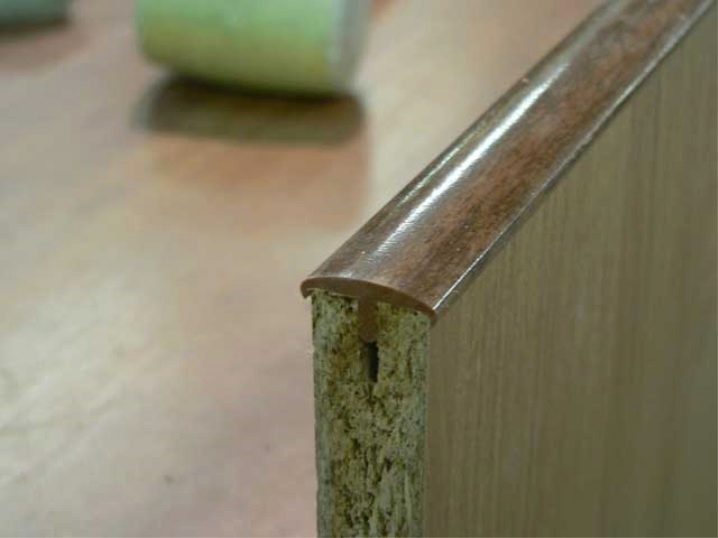

This is how the installation of furniture varieties is performed (for example, they decorate the edge of the countertops). When the cut-in edging is mounted, use an electric milling cutter, an edge mill, a rubber mallet.

A groove is made in the chipboard, placing it strictly in the center. Then a profile is stuffed into it using a mallet. During driving, the profile bends towards itself, otherwise its antennae will not be able to immediately grasp the end of the furniture from both sides.

If in the process of creating a groove it turned out to be more than necessary, the voids are filled with glue.

When working with a brand with a reflective surface, the protective film is removed only after all work has been completed. Otherwise, the formation of defects on the surface of the profile cannot be avoided.

The comment was sent successfully.