Features of profiles for partitions

It is necessary for everyone who decides to equip their homes to know the features of the profiles for partitions and the main dimensions of the partition profiles. They will have to learn another topic - how to make a wireframe. It is also important to pay attention to PVC profiles for sliding partitions and metal profiles, to their other possible options.

Description

Partition profiles are the main components of the frames... It is they who are responsible for keeping the partition in place, for maintaining its basic geometric and strength characteristics. It is absolutely impossible to build any large structure without a profile. The bearing capacity of such profile units and their other important properties must be taken into account. Modern manufacturers can offer many options for profile products, including those differing in material and execution.

The specificity of the profile always concerns the scope of its use:

-

in the whole apartment;

-

for a shower cabin;

-

for a sanitary cabin or a bathroom;

-

for deaf plasterboard partitions;

-

for office use;

-

for various materials (one thing is the same drywall, and another is an all-glass partition).

Varieties

The special features of the profiles for partitions are their large assortment. Let's consider the main varieties.

Guides

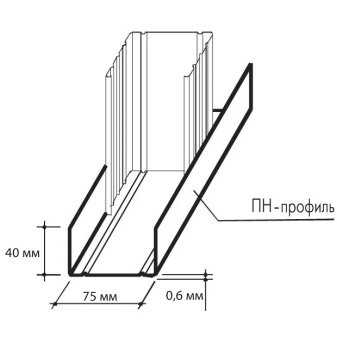

The partition guide profile is usually installed on the floor and on the ceiling. In some cases, it is also installed on the walls, but this is not so common. Such products are designed to provide a very high-quality connection. You need to buy them only from trusted manufacturers who have already proven themselves very well. The standard height is 40 mm, but other dimensional indicators can vary greatly; in many cases, the initial design of the holes is provided.

Even very large companies such as the well-known concern Knauf. In most cases, guide products have a length of 3 m. However, they can be made with other dimensions according to an individual order. It is always necessary to take into account the peculiarities of specific rooms and even specific surfaces, then the probability of error will be minimized.

It is advisable to order profiles from the same firms that supply drywall or other finishing materials to ensure compatibility.

Carriers

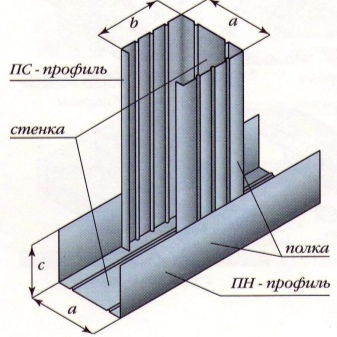

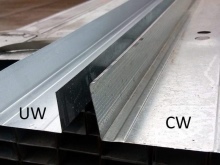

These profiles can also be called rack-mountable; the main purpose of such products is to create a knot in a structure. It is assumed that all such parts are placed in the guides at an angle of 90 degrees. The overall strength of the frame depends on these elements. If it is not large enough, a roll is likely to appear. Concave edges are also no coincidence - this solution allows for the highest holding capacity.

The length of the uprights can be up to 6 m. The sidewall is usually 5 cm. In some cases, the support parts are made of galvanized steel rather than aluminum. Such a decision is quite justified, if we remember about the increased load-bearing characteristics of steel alloys. To further enhance the bearing capacity, corrugated shelves are used.

Arched

We are talking about highly specialized profile products of the most complex shape. They have a convex or concave configuration.On the basis of such products, sophisticated frameworks can be created and visual smoothness of execution can be ensured.

You can easily get a very original curve, thereby increasing the quality of the space design. Initially, designers think over the maximum flexibility of their products.

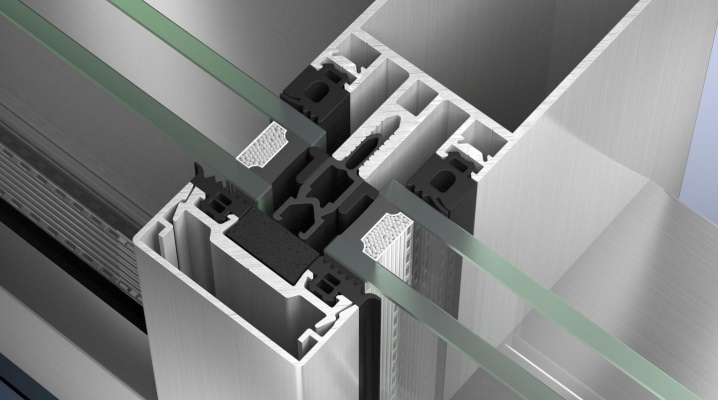

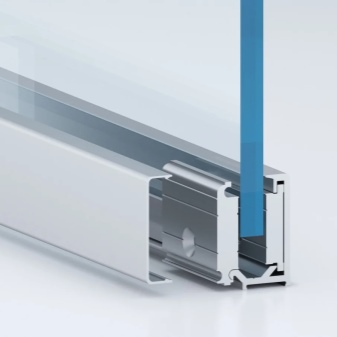

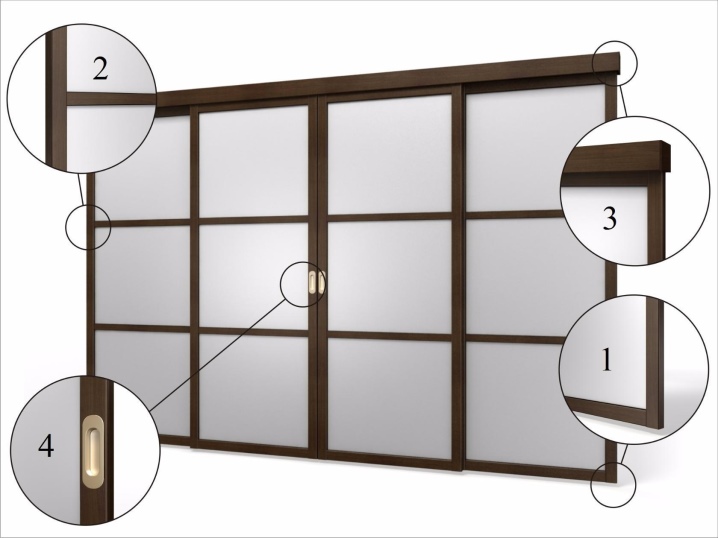

A profile for sliding interior partitions is distinguished into a separate category. Most often they talk about mobile partitions - and this is indeed the case. You can easily move these screens around your apartment or office. Their relief is precisely achieved through the use of a well-thought-out aluminum profile. It is absolutely corrosion resistant, excellent for powder painting; aluminum is strong enough to create partitions up to 3 meters high.

Materials (edit)

Quite often, for reasons of lightness and convenience, a plastic partition profile is chosen. It is quite reliable and chemically inert. Such products have proven themselves very well in apartments, offices, and other premises. PVC-based structures successfully solve both design and purely practical tasks (effectively divide space, distribute zones). Polymer:

-

looks beautiful;

-

easy to use;

-

dampens sound vibrations;

-

relatively robust mechanically.

In some cases, a metal-plastic profile is used. It does not differ much from those used in window production. And they make such products on the same production lines. The declared period of operation is at least 40 years. It is also worth noting the ease of installation and maintenance.

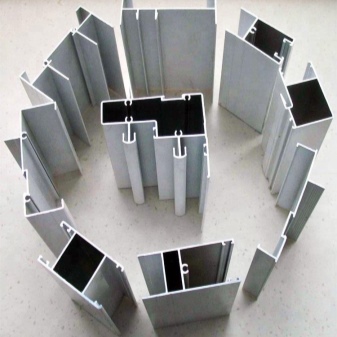

If it is required to ensure the highest possible bearing capacity, a metal profile is used.... Along with pure aluminum, galvanized steel grades are used. They show themselves quite reliably, they work effectively for many years. There is no need to be afraid of any particular severity - modern metal structures are relatively light. You just need to carefully choose their supplier and take into account other subtleties.

Dimensions (edit)

Many experts point out that you need to try to use a profile with a cross section of 50 mm. This is not accidental at all. The same 100x50 mm designs ensure a near perfect fit. But in some cases it is necessary to use structures with a cross section of 60 by 27 mm and other dimensions. Typical lengths of drywall units are 2.4 m, 2.8 m or 3 m; a number of manufacturers can offer models up to 4 meters.

But it makes little sense to look for long profile elements. They have no effect on reliability, contrary to popular belief. The acceleration of the frame assembly does not justify itself. But the thickness of the structure should not be neglected. You need to take a profile that does not bend in your hands - this is quite enough.

Criterias of choice

It should be said right away that the same type of profile structures can be used for both functional needs and for zoning a room. Moreover, it is equally suitable for structures:

-

from drywall;

-

from OSB;

-

from chipboard;

-

from laminated chipboard.

The main thing is that there is enough bearing capacity of the structure. It is calculated according to the mass of the materials used.

Important: it is best to choose products that are equal in length and height to the room, or proportional to these indicators. If this cannot be done, it is more correct to use those structures for interior work that will minimize the number of discarded segments. Otherwise, there are no special tricks.

Installation tips

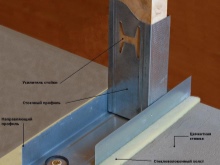

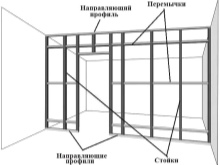

To make a frame for drywall sheets, guide profiles with a section of 50x40 mm are usually used. There should be just enough of them to successfully sheathe the entire required perimeter. The optimal size of the rack profile is 50x50 mm. Experts recommend choose dowels and screws of two lengths - 35 and 45 mm. The first ones are useful when attaching sheets to the frame, and the second ones - for mounting the frame elements themselves; their installation allows you to attach jumpers.

A very important stage is preliminary marking. Errors at this stage are most often irreparable. The future partition should be marked from the floor from bottom to top. For single-layer sheathing, it is required to indent inward from the main line by the thickness of the sheet used. The new line will show you exactly where to place the guide profiles. When it is completed, you can transfer marks to ceilings and walls; it is best to verify these figures with a laser level.

The easiest way to assemble the frame from the guides is to start from the floor.

To enhance sound insulation, a sealing tape is glued to the floor and ceiling at the installation point. You can always buy it in the same stores as the profile itself.

They usually try to attach the guides with dowel-nails, and self-tapping screws can be driven into the wooden floor. Only after marking the perimeter with guides can you start cutting rack-mount profiles to size.

Rack elements should be 1-1.5 cm below the ceiling. Then exposing the structure will not be difficult. The distance between the profiles is kept exactly such that the joint of the sheet falls into the middle of the support. Additional reinforcement of the assembly is made by horizontal bridges. To make it easier to put doors and windows, they use embedded bars.

The comment was sent successfully.