Features of MDF profiles

MDF profile is a relatively new product on the construction market. The material is made from MDF board (wood waste and binders), the material is made in any shape. After production and certain processing at factories, MDF profiles are used in the manufacture of furniture, facades of furniture sets (usually for the kitchen), interior doors, window frames and door frames.

general description

MDF is a natural material, environmentally friendly and safe. Products made from this material are used in children's rooms, preschool and school institutions, furniture made from MDF profiles will not emit harmful substances and fumes.

MDF is made from the remains of dried wood fibers with the addition of synthetic binders. The slabs are formed in the form of a carpet, pressed under high pressure and temperature, and then sanded. The abbreviation MDF stands for microdispersed fraction. This is a new and improved technology in the production of fiberboard.

The density of MDF profiles is comparable to that of natural wood. MDF lends itself to complex processing, milling and grinding. On its surface, you can apply a pattern of any complexity or cut out a profile of the most intricate shape. The surface of MDF can be painted, varnished and laminated. This expands the possibilities in the areas of application of MDF and makes it a versatile material. This is especially important for furniture production. The flexibility of the material allows you to work with it with both hand and power tools.

The synthetic binders used are environmentally friendly and emit a minimum amount of harmful substances during operation. MDF profiles are resistant to fungi and other pathogenic microorganisms. This makes furniture made of it safe for people and pets.

MDF profiles are also called frame, furniture, decorative or sometimes facade. In fact, all these names characterize the material and the scope of its application.

Views

MDF profiles are made from plates, giving them various shapes and applying a special coating. It provides thousands of color and texture options for MDF profiles. There are several types of coverage.

Finish film. The cheapest and most common option. But the quality is inferior to other types of coating. The paper covering does not withstand rough impact and long-term use.

Natural veneer. Has the appearance of natural wood. Veneered material is less resistant to damage and environmental influences. The price is often unreasonably high.

PVC film. Optimal coverage for MDF profiles. The price corresponds to the quality and characteristics of the material.

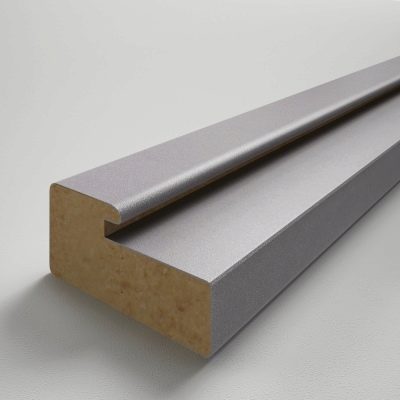

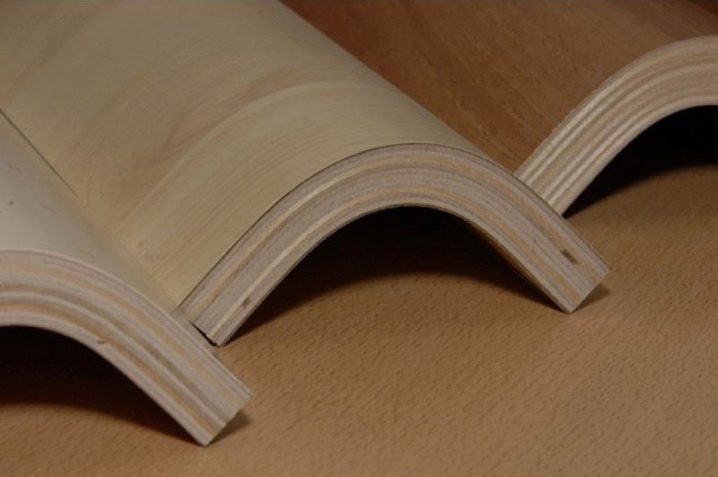

In its original form, the profile has a grayish-brown color on the cut with a dense homogeneous mass. Then it is painted or a special coating is used. Due to its high strength, it can be bent and given any shape and size.

The radius profile is most often used for decorative purposes, for the design of facades.

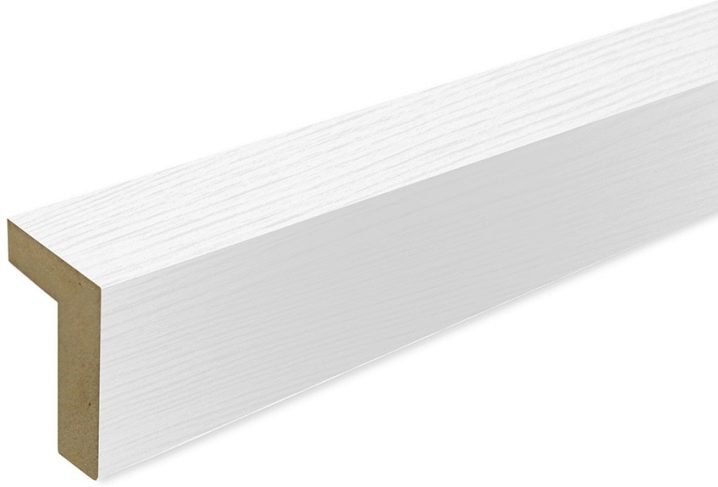

The U-shaped profile is used in the manufacture of door and window blocks, or when installing MDF panels on a wall or ceiling. A white rectangular frame is formed from them, into which a filler (chipboard, plastic or plexiglass) is inserted. Later it is painted or covered with veneer or foil.

The overlay profile is widely used for finishing furniture and facades. The overlays can be of various shapes (C, G and U-shaped or regular rectangular).The overlay profile is used in the production of nightstands, dressers and beds. They serve both decorative and protective functions.

Most often, the linings are covered with a PVC film that imitates the texture and color of wood.

Application

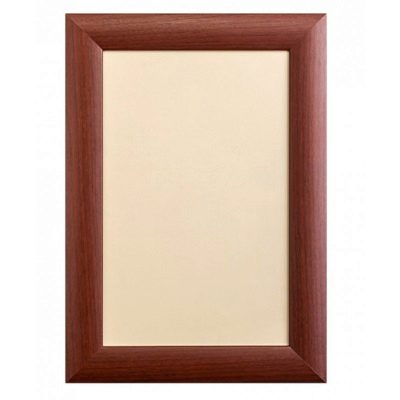

MDF profile is most often used for the production of furniture, especially for kitchen facades, namely: to decorate the front doors of cabinets, to create decorative elements of fixed parts of cabinet furniture. Often used for cabinets with hinged doors or drawers.

The widespread use and popularity of MDF profiles for cabinet furniture is due to the characteristics of the material:

-

resistance to wear and environmental impact;

-

resistance to scratches, chips;

-

ease of maintenance, resistance to chemicals;

-

wide range of colors;

-

environmental friendliness;

-

water resistance;

-

resistance to dirt and dust.

Facade frame made of MDF profile can be filled with any other material, such as glass, mirror, chipboard or rattan. The design is lightweight and can be used in any part of cabinet furniture. Strength and high density allow you to cut parts of any shape and apply a carved pattern on them.

Of the minuses of furniture made of MDF-profile, it can be noted:

-

seam joint and its rapid contamination (especially for kitchen furniture);

-

possible peeling of the PVC film in conditions of high humidity and temperature;

-

low resistance to moisture of natural veneer coating.

Despite the disadvantages of the material, it is currently the most widespread and in demand due to its affordable price and wide selection.

Furniture production is not the only area of application for MDF profiles. The material is also used for the design of window and door openings, the manufacture of door frames as a whole. It is very difficult to list all the areas of application of the profile due to its prevalence and availability. This profile fits harmoniously into any interior, from classic to high-tech. The possibilities of using the material are expanding every day.

The comment was sent successfully.