All about U-shaped profiles

When performing various finishing works, profiles are used. They can have various shapes and sizes. They can also be made from various materials. Today we will talk about the features of U-shaped profiles, their varieties.

Species overview

To begin with, we will analyze what U-shaped profiles exist, depending on the material from which they are made.

Metallic

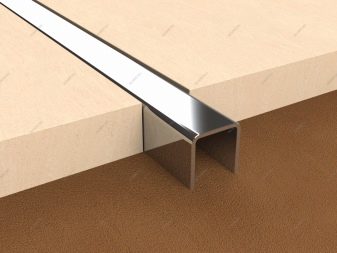

These parts are usually made of aluminum or steel (both hot-rolled and cold-rolled steel can be used). Also, galvanized and stainless metals are often used, they practically do not corrode.

Galvanizing metal involves applying a thin layer of a special zinc-containing composition to its surface. This procedure provides maximum protection of the product from rust and the formation of oxides. Metal with such a coating will not be afraid of moisture, chemicals.

Metal models have a relatively low mass... At the same time, they can boast of a high level of strength, reliability and resistance to external negative environments. These profiles are also particularly durable. On average, their service life is more than 50 years. Structures made of such material are easy to process and cut.

They are able to withstand sudden temperature changes, so they can be used for exterior decoration as well. If necessary, P-shaped profiles can be coated with a wide variety of paints and varnishes.

This improves their decorative qualities. Often they are made white, black, and copper, chrome-plated flexible options can also be seen in stores.

Silicone

Silicone has high adhesive properties, it is resistant to sudden temperature changes. In addition, this material is considered to be quite strong and durable. It is also highly resistant to UV radiation. Profiles made of silicone are flexible. They can have a wide variety of colors. They are as easy to use and install as possible... Silicone samples will not lose their elasticity even during long-term use.

These profile structures are considered absolutely safe. They are non-toxic and will not release harmful components during use. Currently, special heat-resistant silicone profiles are also produced. They can even withstand very low or high temperatures.

Such models are created with a special heat-resistant additive. Most often, such samples are used in heat chambers, fire-resistant doors.

Silicone parts do not absorb unpleasant odors and dirt. They can be cleaned using chemical detergents, disinfecting liquids.

Wooden

U-shaped structures can be made from various types of wood. Most often in stores you can find softwood profiles. During the manufacturing process, the material must undergo careful preparation and processing. It is covered with antiseptic agents that will protect products from mold, fungal organisms, rodents, and biological decay. Wooden profile products are distinguished by their beautiful appearance. They are versatile and can be used for various repair work. Window openings decorated with such profiles will look unusual.

In addition, such products lend themselves well to various processing and drying. Wood models are particularly durable. They are easy to paint. Sometimes only a transparent protective varnish is applied to the surface.

In case of damage, you can simply remove the old layer of paint or varnish, sand the surface and cover it with a new decorative layer.

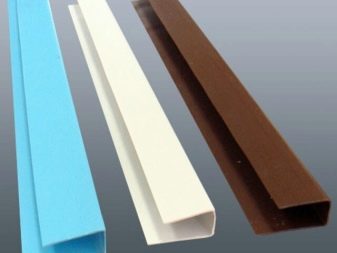

Pvc

Samples made of PVC have good thermal insulation performance. They allow you to maintain natural air exchange between the enclosed space and the street. Such products have an aesthetic appearance. But at the same time, profiles made of such a material are distinguished by low resistance to fire, a relatively high cost. They are used for finishing, as well as when creating slopes. They can be installed both outdoors and indoors. In the first case, the products will tightly close all the cracks, preventing moisture penetration.

By design features, the following types of U-shaped profiles can be distinguished: special, lightweight, economical, with sloped edges, with parallel edges. In addition, the end version should be distinguished. It is used in cases where it is necessary to prevent the negative impact of precipitation on the edges of buildings. Often, end models are used when arranging polycarbonate structures. Such samples are put on the edges of the surface. They provide maximum sealing and reliability.

For the best effect, you can additionally use special flexible tapes.

Such curved profile structures can also be divided into two more large groups.

- The main... They are marked "PS" or "PP". They are designed to support significant weight loads. They can be taken as a fastener for GLK.

- Guides... These models are marked with the combination "PN". They act as a horizontal base for the uprights. They can also be taken for fixing GLA.

Separately, it should be noted and protective U-shaped profiles. They allow you to protect facades from various mechanical damage. Such details are often used in the manufacture of various furniture designs.

There are also models that serve only a decorative function. They can be made from different materials. As a rule, they are painted during the manufacturing process. If necessary, you can choose the right option for any interior style.

Special U-shaped strips for C8 corrugated board are also produced.... Most often they are used in the construction of metal sheet fences. Such details can significantly increase the rigidity of the structure, protect the edge of the sheets from water ingress. Some models of such products are perforated. Perforated specimens are highly resistant to corrosion. It is achieved through the use of galvanizing and special alloying additives.

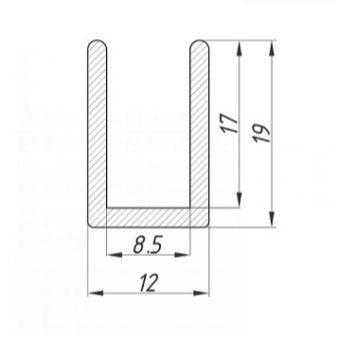

Dimensions and weight

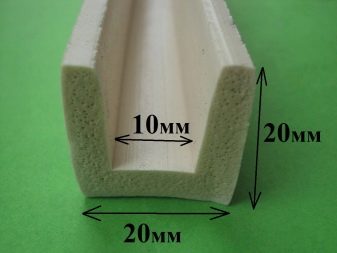

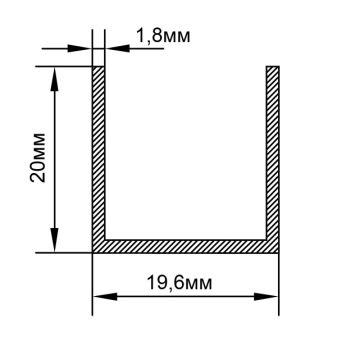

Profiles in the shape of the letter "P" can have different dimensional designations (shelf height, back width, thickness of the material used). All of them are registered in GOST 11474-76... You can also find this information in other GOSTs dedicated to individual varieties of such profiles. Most often, when carrying out finishing and construction work, models are used 20x20, 25x25, 50x50, 30x30 cm, 60x27, 100x20, 80x20 mm. In this case, the thickness can reach 6, 8, 10, 16 mm. The standard length of the product is most often 2, 3, 4 meters.

The weight of such products can vary significantly depending on what material they are made of, as well as depending on the size. So, the weight of 1 running meter of such profiles can vary from 1 to 10 kilograms.

Top brands and labels

Next, we will get acquainted with the most popular manufacturers of U-shaped profiles.

- GAH ALBERTS. This brand specializes in the production and sale of quality metal profiles. Most often, durable and machined aluminum is taken as a basis. The company's products can be created with a chrome finish. Such structures for finishing works can be made in various sizes. All products are lightweight and easy to install and dismantle.

- No Name. This brand produces profiles from various materials, including aluminum, softwood. Metal structures are made with anodized coating. It allows you to maximize the resistance and durability of products.

These brand products are resistant to mechanical stress and deformation. The assortment also includes completely uncoated samples.

- "Luke"... This brand also produces profile structures from various materials (aluminum, stainless steel, PVC). The manufacturer manufactures a large number of parts that are used as guides and connecting elements. They can be used for decoration of premises, in the manufacture of furniture, in the production of frames.

When choosing a suitable profile structure, you should pay attention to the marking. So, the inscription "ППС" will mean the profiles that are used for the installation of ceilings in the premises. Sheets of drywall are attached to them. The inscription "PS" will mean parts that are fixed as wall rack elements. "PPN" are intended for fixing the finishing on the ceilings.

Currently, special profiles PSL, PSM are also being produced. They are designed for cable management. They are usually manufactured from durable and high quality galvanized steel. These models are distinguished by an increased service life, special reliability, and resistance to mechanical stress. Sometimes such models are also used when installing various supporting structures, suspended systems, ventilation ducts. These samples are made with perforation from three sides at once.

Applications

U-shaped profiles made of various materials can be used for a wide variety of repair and finishing work.

- So, they are often used in the construction of load-bearing structures. Most often, samples from aluminum and steel are used for this purpose. They can be useful when arranging roofs, supporting structures, vaults. In addition, such details are taken during the construction of various enclosing structures, including simple partitions, walls. Such structures should be lightweight and stable. They are designed for moderate weight loads.

- Also, these parts can be used for laminate... In this case, they allow you to hide all the ends of the coating.

- Sometimes U-shaped elements are also taken for corrugated board when erecting fences, street partitions, for chipboard.

- This type of profile is used when fixing drywall... In this case, guide parts are used, which are fixed along the entire perimeter of the surface.

- In some cases, U-shaped elements are taken when installing siding... For this, metal samples are also selected. From them, a solid lathing for siding is made.

- Profiles in the form of the letter "P" are also purchased for fixing insulation boards, for arranging ventilated facades. They are also suitable for creating metal window openings, filling the latter.

- Parts of this type have found their wide application in mechanical engineering.... They are used in the manufacture of a variety of mechanisms, when performing electrical installation. In agriculture, they are also used (when installing trellis supports, when building greenhouses and greenhouses).

- When laying wiring and other similar systems, thin-walled metal samples with perforations are taken. They are connected to each other using bolts. Resistance of treated metals to high temperatures will exclude burnout and ignition of the wiring.

- Silicone products can be excellent for sealing gaps and joints... Such seals are characterized by excellent heat resistance. With sharp temperature changes, it will not decrease.

The comment was sent successfully.