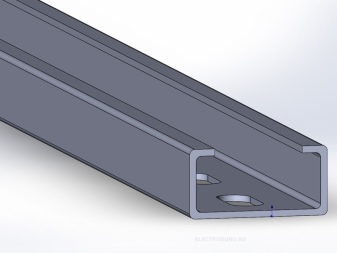

Perforated C-Profile Overview

Various engineering structures include many elements. These include the C-shaped perforated profile. A detailed overview of these mounting rails will enable you to select the right products for non-welded structural assembly.

Description

Traverses (profiles) are made of stainless or galvanized steel, you can also find aluminum products. The metal can be additionally powder coated to protect it from rust and extend its useful life. Mounting rails are processed on bending machines - this allows you to give the products the desired shape. Traverses usually have holes in the base, but there are options with perforations on all three sides. Production is regulated by GOST 8282-83.

A distinctive characteristic of such a profile is increased rigidity. It is also called beam or rack-mount, since it is often used in the installation of these elements. Tires of this type can be used for the assembly of structures designed for a serious load.

The perforated C-profile has certain advantages that make it popular in the market:

-

work with these products does not require a welding machine, all fasteners are connected by hardware;

-

perforation allows for DIY installation, including the use of tires for private use;

-

products differ high strength, they are protected from corrosion and can last a long time;

-

light weight does not make the structure heavier and does not create unnecessary load on the base.

There is a wide range of similar elements on the market, so you can choose options for any purpose.

Views

The products are produced in whips with a standard size from 2 to 6 meters. It is also possible to manufacture according to individual parameters. In terms of dimensions, profiles of 30x20x3000x1.5 mm, or 80x40x3.0 mm are often chosen. The choice of size depends on the load that the structure must withstand and the parameters of the finished structure.

And also the elements are divided into three groups:

-

K101;

-

K108;

-

K110.

They differ in the height of the shelf, which can be up to 50 mm, in width - up to 100 mm, the number of holes, and weight.

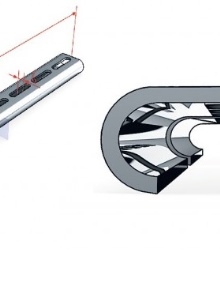

On sale there are strat profiles that are very reminiscent of C-shaped ones. They are distinguished by a different bending angle at the ends of the rails. And also when working with these metal elements, you need to use special channel nuts for more reliable fixation.

According to the type of coverage, the profiles are divided into two groups.

-

Galvanized traverses - more resistant to weather conditions. Hot dip galvanized.

-

Powder coated - have an attractive cost. A special paint is applied to the surface, which forms a protective layer.

The most popular manufacturers of metal elements are DKC, HILTI, IEK, OSTEC. These are companies that have earned a good reputation in the market, they do not save on raw materials and produce quality products.

Applications

Versatility and high performance indicators allow the use of a punched profile in various areas:

-

for the installation of warehouse structures, the organization of racks and similar storage places;

-

when arranging engineering communications - ducts through which cables are laid, ventilation or lighting systems, pipelines of various formats;

-

during construction - for facing work, when installing roof structures, for laying insulation, when finishing the facade, for strengthening structures made of plasterboard;

-

in the furniture industry - profiles act as a solid frame.

Also, products are in demand for private needs - they are used when installing greenhouses in the country, used for installing shelves and utility racks.

If necessary, metal tires with different cross-sections can be combined, which opens up even wider possibilities for the manufacture of structures for industrial or domestic use.

The comment was sent successfully.