Features of plastic U-shaped profiles

Plastic U-shaped profiles, made, for example, of PVC, are one of the most demanded materials for interior wall decoration. They replaced wall panels made of fiberboard, chipboard or solid wood. Wood and metal are a sign of luxury, but plastic is available to people even with a modest income.

general description

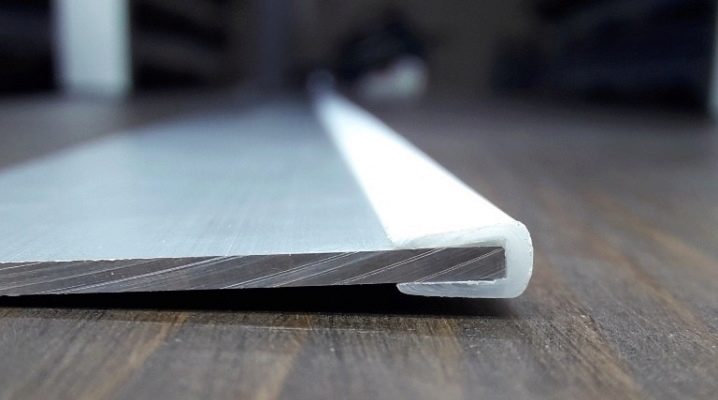

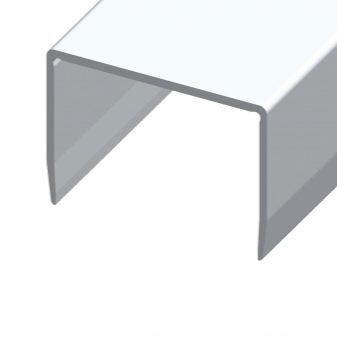

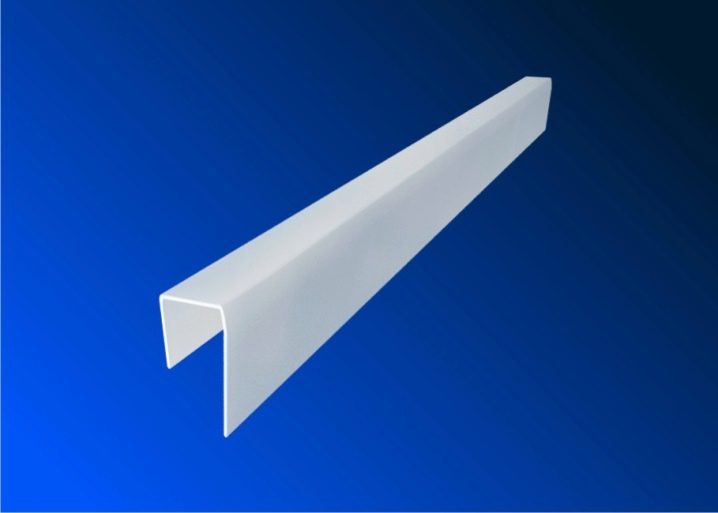

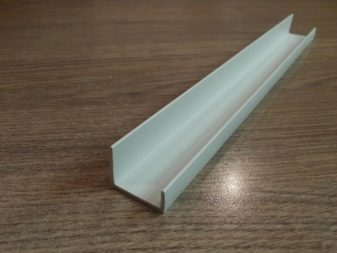

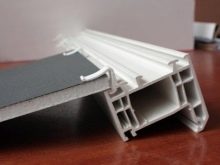

U-shaped plastic profiles will complement any interior decoration - they allow sheets of plywood or the same plastic to take a finished look. Edging PVC is produced in the form of corner (L-shaped) in the section and U-shaped profiles. The latter have found their application in the organization of thin-walled partitions, from screens to retractable structural elements. The purpose of the U-shaped profile is to hide from prying eyes possible flaws when sawing sheet plastic, wood and metal panels.

Any plastic does not rot or decompose from moisture. However, not all types of plastics withstand the effects of ultraviolet rays, daily and seasonal (annual) temperature fluctuations, overheating in the heat and hypothermia in the cold, so the original properties are gradually lost.

Because of this, it is not recommended to use plastic trim for outdoor work.

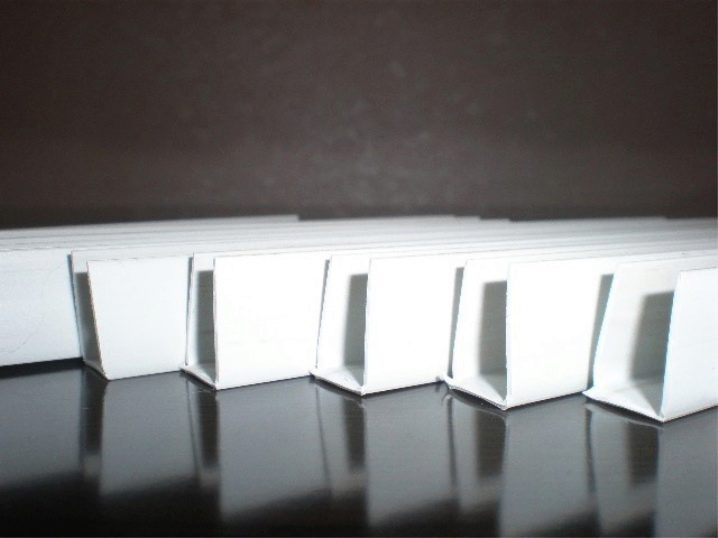

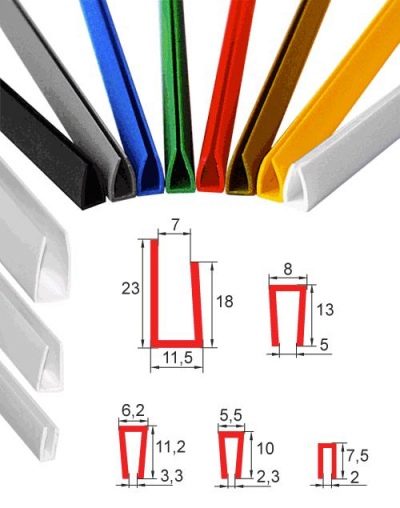

White, yellow, gray and light cream colors of plastic with a pattern or pattern, a repeating texture are most often chosen to match the color scheme of room design. For finishing the side and main walls, the profile has a wide range of sizes, but the most popular (according to customer statistics) are the following: 4, 5, 6, 8, 10, 16, 20, 30, 40, 45 and 50 mm.

The wall thickness depends on the cross-sectional dimensions of the profile part. For example, for a profile with 50 mm walls, the thickness can be 2-4 mm. When choosing a certain component, these characteristics are taken into account without fail. From an 8 mm profile with 4 mm walls, the appearance of the edged panel could suffer - with a small size, the sides (walls) are too noticeable to an outside observer. But a 50 mm profile with 1 mm thick walls will quickly be damaged during packaging, transportation, storage and / or installation. In addition, it is not as reliable in its seat as customers would like it to be.

The slots, closed, for example, in a porous-channel wall panel, produced not as a solid, but in a cellular one, with a U-profile from the edges of the panel sheets, do not allow dirt, dust, and moisture to get into the cells. In addition, there is no way for insects, molds, fungi to grow there, microbes multiply, partially destroying and processing the biodegradable modification of polypropylene, PVC or polyethylene.

Aesthetic component - perfect fit of adjacent panel sheets to each other. It is difficult to use a P-profile here: for this purpose, the form "Tavr" is used. You can paint the scratched and rubbed plastic of both the panel itself and the profile if you first sand it with the smallest abrasive available today. The mechanized "sweep" uses emery wheels.

Compared to metal U-panels, plastic ones are noticeably lighter. At room temperature, they are not afraid even of streams of water, they can be easily washed using ordinary laundry soap.

It is extremely difficult to electrify most types of plastic, and this is important if there is a microelectronics sensitive to discharges nearby that does not have additional protection.

Views

In addition to the light shades that are given to plastic profiles in production, you can often find other solutions - black or bright colors of these products. The specific color scheme depends on the preferences of the customer and the samples available on the market. Some types of plastic (like polyethylene) are more flexible than others. If we take polystyrene and polypropylene, then they, allowing slight bends, will simply break with strong bending. Polypropylene cut to ⅓ of the thickness breaks without special tools for scrapping and cutting.

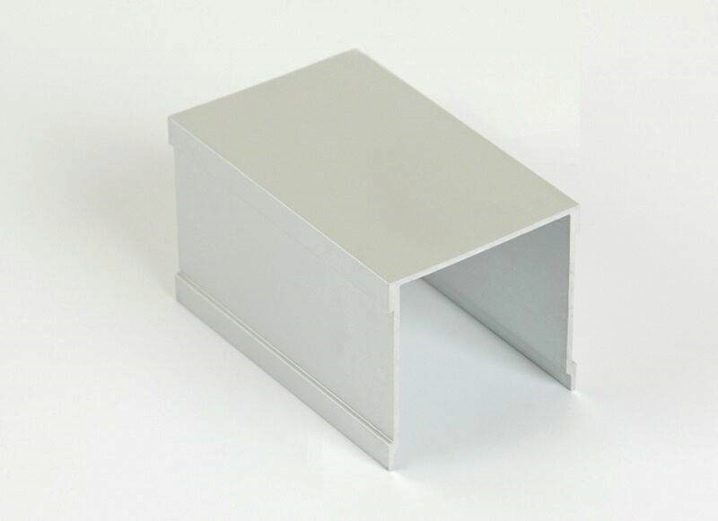

The dimensions of the edging P-profile range from 4 mm (the width of each of the walls) to several centimeters. The use of larger and thicker-walled U-profiles forces them to be used not as an edging of a much thinner (up to 1 cm) wall panel, but as a U-shaped casing or cable / pipeline in-wall, underfloor or ceiling gutters.

By texture, buyers are offered an imitation of wood, stone, brickwork (with a 3D effect that can be felt by the touch), metallization (powder coating), matte or glossy surface effect, "playing" in the sun. Zoning of premises is achieved only by changing the colors. For example, the "patch" for the curbstone and poufs is highlighted in a brown shade of the U-shaped profile of the wall cladding, and the other part of the hallway, into which the doors of the rooms and the kitchen-living room open out, in pink-yellow. The end of the hallway and the door of the bathroom are distinguished by white-gray profiles that delimit the wall panels in this area of their location.

There are several groups of P-shaped profiles by types.

-

Starting U-profile, or plank. Such a profile delimits the end faces of the panels when they are open and do not join with the same adjacent elements. The disadvantage is the edging of only one wall or part of it (they cannot be supplemented). Available as 3 and 6 meter blanks.

-

Connector. As a rule, it turns out not a U-shaped, but, for example, an H-profile. You can get the "H-effect" by connecting two P-profiles with end "backs" to each other, fixing them with glue "Moment-1" or sealant ("liquid nails"). The gap of such a bar is from 5 mm.

-

Corner. In addition to the U-shaped, the F-profile is also used. It is a corner piece. True, it is difficult to apply the P-construction here. The length of the workpiece is 1.7-6 m.

-

Universal U-profiles. They have good flexibility, they are wound in turns on the drum, they are produced both with an overlap and “set” on glue.

For P-profiles, plastic thinner than 1 and thicker than 8 mm is not used.

Selection Tips

For siding, panels should be selected from the same types of plastic that are intended for outdoor use. Most often it is vinyl. The colors are used either in contrasting or approximately the same tone. The most important requirement is non-combustibility: plastic should not support self-combustion.

Any plastic that does not emit toxins at room temperature is suitable for furniture. Polyethylene, polypropylene, PVC are just such types of plastic. They differ from the brittle and more toxic polystyrene, which, when exposed to direct sunlight, emits styrene vapors that can cause cancer if people are present for a long time. For non-residential premises, where the temperature is often elevated (kitchen, furnace), it is better to abandon plastic and use, for example, an aluminum U-profile.

The same recommendation is valid for outdoor sandwich panels, soffits and other similar solutions for external finishing: the temperature in these places often and significantly fluctuates.

Even a master who does not have much experience in such work can mount plastic panels.

Installation

Decide on the number of elements to be installed by consulting the project of finishing the object. P-strips are fixed on self-tapping screws, the heads of which are painted in a similar or the same color (so that the fasteners do not stand out). The distance of the edge of the hardware head from the edge of the part is at least 5 mm. For the installation of cut parts, the corresponding P-transitions with grooves are used, the spike in which is the edge of the cross-section. If necessary, these joints are covered with glue from the inside. Do not use glue when the black panel can heat up to +80 degrees in summer in the heat.

When installing sheets on the ceiling, each sheet is brought into its intended place from three sides. After making sure that the sheet has gone into the U- and H-profiles all the way, and the general arrangement is not disturbed, they put the last - fourth - element. The sheet is closed, you can put the next one.

If necessary, the sheets in the profiles are fastened with self-tapping screws to protect against accidental displacement in different directions. But in cases where not a living room is faced, where in summer and winter the temperature is maintained at a stable level using automation, but, for example, a warehouse, it is recommended to leave a deformation (temperature) gap on each of the panels.

This is done using slotted holes in the siding panels.

The comment was sent successfully.