All about the edging profile

In the furniture and construction industry, it is constantly required to decorate the joints, protect the open edge. In these and other areas, various types of profiles from a variety of materials are used to cover joints and joints.

Features and purpose

Edging (edge) and edge (edge) profiles are a wide range of proposals for decorating joints, joints at any angle. All profiles are divided into several types.

- docking;

- edging;

- connecting.

Profiles are used in areas such as:

- construction (finishing works with plasterboard, siding, clapboard, plastic and MDF panels);

- furniture production (finishing of furniture edges with flexible PVC edges of a straight or rounded shape).

The edge profile is always popular due to its simplicity and ease of use. It is impossible to do without it when working with sandwich panels: all ends require edging, otherwise the finished areas not only lose their visual qualities, but also become vulnerable to the aggressive effects of the atmospheric environment.

Manufacturing materials

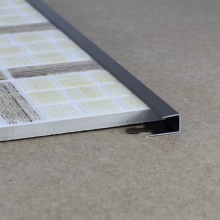

Edge profiles have a wide range of sizes: from 3 to 40 mm and more. The U-shaped profile is used as a decorative frame for panels, stands, signs, plates. Manufacturers offer connecting, edging, butting profiles made of solid materials. So, these are the following options:

- brass;

- aluminum;

- galvanized;

- made of stainless steel.

Such materials have excellent anti-corrosion properties and have a large margin of safety. Stainless steel edging profiles are different in their structure. There are the following edge products:

- polished;

- satin;

- decorated.

The PVC edge is made from refined products with the addition of table salt (more precisely, ethylene and chlorine, which is part of the salt formula). As a result of mixing, dichloroethane is obtained. The final of the subsequent two-stage reaction is polyvinyl chloride - the familiar PVC.

The initial consistency of the product is a colorless, odorless powder. The finished edge is most often a plain pigmented product, but it can also be with a pattern, for example, wood.

PVC products are considered safe up to a certain limit: when heated above 100 degrees, the product begins to release hydrogen chloride, which depressing the respiratory organs.

During standard operation, the plastic edge protects against harmful vapors of the impregnating composition MDF, chipboard, chipboard... The material not only possesses decorative properties, but is also chemically resistant: it successfully resists various types of acids, alkalis, etc. The flexible PVC edge is a product in coils sold by the meter. Furniture edge can be made:

- made of metal and plastic;

- melamine;

- acrylic.

The differences between the products are in size, fastening methods, and also cost.

Types and sizes

The geometry of the profiles is quite varied. The following options can be distinguished:

- U-shaped;

- L-shaped;

- J-shaped;

- H-shaped;

- U-shaped;

- L-shaped;

- oval;

- square;

- radiator;

- drop-shaped, etc.

Furniture flexible edge fittings are presented by manufacturers in various standard sizes.

|

Type of |

The size |

|

melamine |

product thickness - from 0.2 to 0.4 cm, width - 26 mm |

|

PVC (polyvinyl chloride) |

edge thickness - 1.2 mm, width - 26.5 mm |

|

acrylic (ABC) |

width - 19-22 mm, thickness - 0.4, 1, 2, 3 mm |

|

waybill |

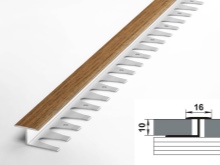

width - 16-18 mm, thickness - 30-40 mm and more |

Without the use of edging, modern furniture production will not be able to produce high-quality and beautiful furniture from natural and composite materials.

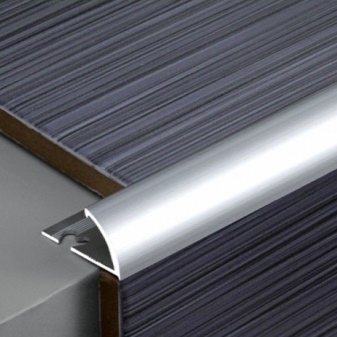

- edging, there are edging straight and curved profiles. Their options are:

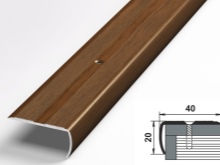

- models for steps and facings;

- compensation and structural products for joints;

- diaphragms for finishing balconies, terraces, verandas.

Manufacturers produce aluminum profiles in a wide range of colors:

- light and dark maple;

- beech, cherry and walnut in various shades;

- very beautiful light and dark rocky oak.

In addition, anodized profile is produced in various shades.

Areas of use

The edging profile is widely used in indoor and outdoor advertising: posters, plates, banners, posters, signs and so on.... Construction external and internal finishing work, the production of windows - all this, too, will not do without plastic, aluminum profiles. In landscape design, such products are needed to decorate borders, decorative walls, gazebos, terraces, pergolas, pools and other artificial structures.

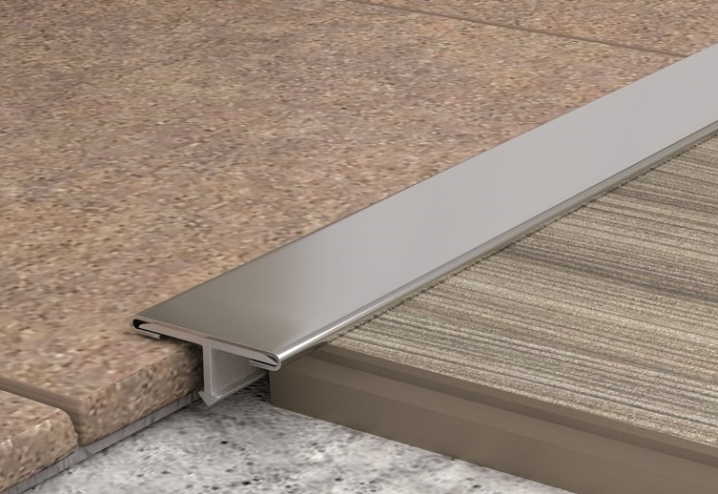

The L-shaped profile is used to complete the floor covering or as a curb on a tiled area. A large assortment ensures the demand in any variant. A U-shaped edge profile made of stainless steel is used in the final stages to perform tasks in internal and external work. With its help, most often problems are solved in the field of repairs in closed rooms. The edging of floor coverings, panels of any type, sheet materials will allow you to give the repair a finished look, harmoniously fitting or connecting dissimilar surfaces. The edging for gypsum plasterboard (drywall) will not only make the appearance more neat, but also protect the material from moisture.

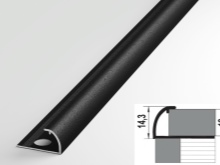

The oval profile is, rather, a design solution for interior tasks... Oval copper, aluminum, galvanized profile looks very presentable in the interior and furniture structures. Radiator profiles are in demand for cooling microcircuits, drivers, they are indispensable in passive cooling of voltage stabilizers, when installing and installing LED systems.

The comment was sent successfully.