Application of aluminum H-shaped profile

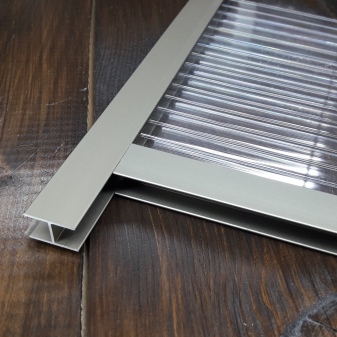

The H-shaped profile is the main component of windows, doors, screening partitions made of metal and plastic. With an H-shaped structure, it is easy to organize a viewing window, a sliding or sliding door and many similar structures.

Peculiarities

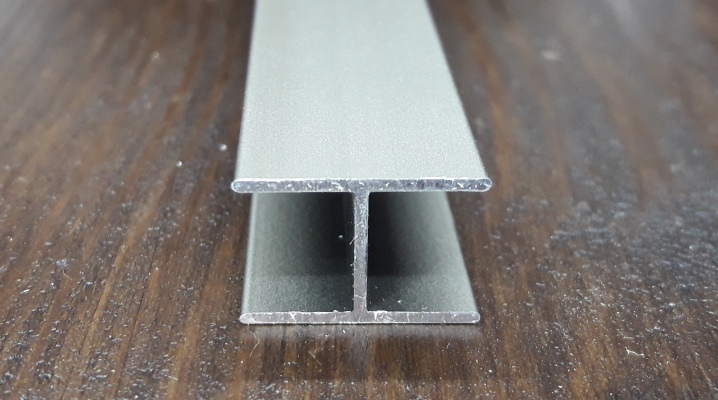

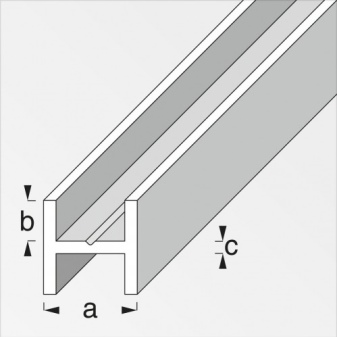

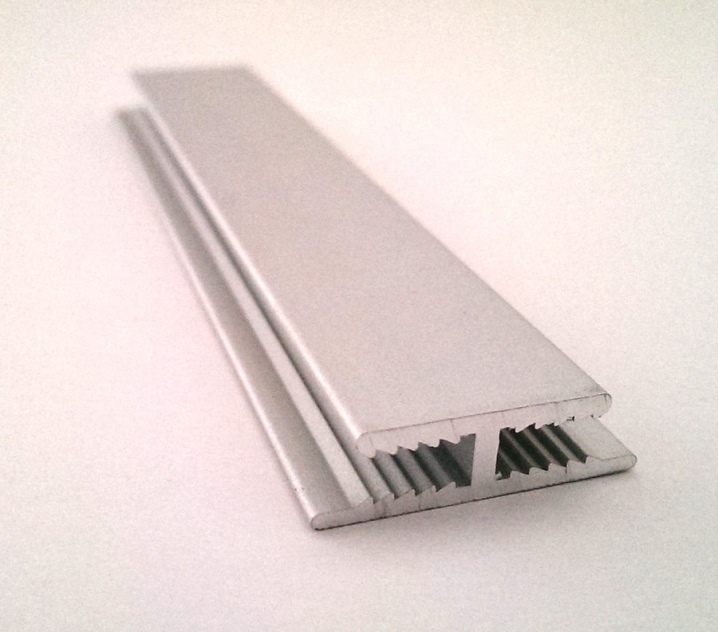

The main distinguishing feature is the cross section of the metal profile in the form of the letter H. The vertical sides of this "letter" may differ or be the same. The thicker the walls of such a profile (longitudinal and transverse), the stronger the product. The greater the load from glass, plastic panel, composite insert or even a board, it will withstand.

H-structure - in its absence - can be assembled:

- from two U-shaped segments, equal in width to the upper part;

- of two C-shaped, with curved flanges along the edges of the side faces;

- of two single T-pieces (T-shaped pieces).

In the latter case, welding is indispensable. If the U- and C-shaped profiles can be connected with bolted fasteners (at least at the ends), then the welding of the T-parts is performed by a professional welder with experience in laying "recumbent" (horizontal, "floor") seams. Welding of T-profiles is carried out according to the "crescent" method, zigzag or circular (rotational) movements at the point of contact of the electrode with the surfaces to be joined. The resulting connecting "I-beam" must have strictly parallel edges and edges. It does not bend, retaining its shape and structure under adequate loads, for many years.

There are also H-sections with one rounded, inwardly curved vertical side. The thickness of such a wall may be variable - thickening towards the edge and thinning closer to the transverse edge, or vice versa. This gives the structure smoothness, improves its appearance, makes the structure or piece of furniture, interior more presentable.

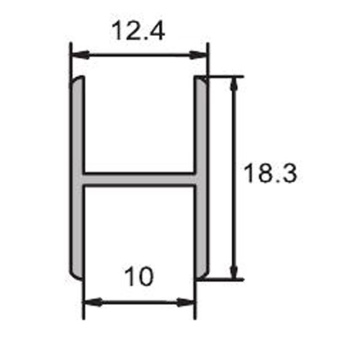

Dimensions (edit)

The steel profile is made with walls up to 2-3 mm thick, aluminum - 2-3 times thicker due to the significantly lower mass of aluminum. The thickness of the profile walls is from one to several millimeters.

The size of the gap of the H-shaped profile fluctuates depending on the task assigned to the product. So, the organization of a "multi-storey" shelf or rack with a closed compartment, divided at different levels, will require sliding glass. The lower, side and upper profiles are taken in the form of W- or U-shaped structures, and the "interfloor" ones are H-shaped, placed side by side and vertically.

The condition here is this: horizontal ceilings should not go out - they are recessed inside the space delimited by the walls of a shelf or bedside table and sliding glasses. They are parallel to each other and to the horizontal walls of this product.

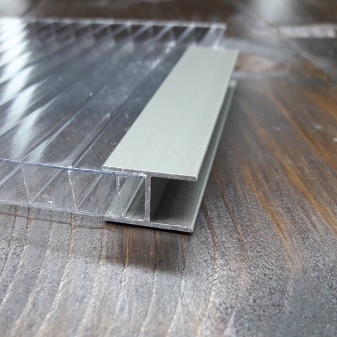

An H-shaped profile is produced with a gap width from units to tens of millimeters. Typical values are 6-, 8-, 10-, 12-, 14-, and 16mm gaps. The length of the profile sold in sections ranges from one to several meters. 6mm is often used as a docking - in places where the segments should not be easily attached to each other.

Where is it applied?

The H-structure is primarily a docking one. It holds a sheet of other material (glass, board or plywood, chipboard element, sheet of steel or composite layers in the form of a square / rectangle). First of all, the H-profile is a cladding component. An example is an armstrong type suspended ceiling in a kitchen or dining room of a particular establishment, with steel or aluminum squares.

H-profile is the main component of the cladding of buildings (for example, it is part of the soffits), the roof (if there is no access to the profiled roof). The I-beam support structure is versatile - it can be mounted horizontally or vertically.

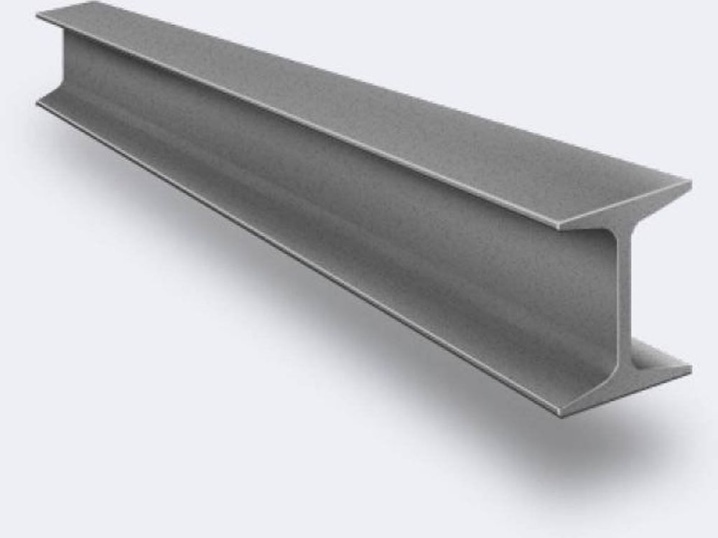

Steel I-beam - thin-walled and with walls below average thickness - the basis for plasterboard and wooden partitions. They allow the owner of the living space to re-plan a house or apartment - for example, to split one large room in two.

A thick-walled I-beam - with a steel thickness of 10 millimeters or more - is an assistant in organizing new door and window openings. It will easily take on the multi-ton load of brickwork and sections of interfloor floors, holding the part of the wall located above, above the opening itself. Such a product is used not in one, but in two or more elements - the letter H in the cut is placed "lying", a double (triple, and so on) H-shaped profile is formed, which has internal closed spaces.

The industries in which the H-bar or H-beam is used are as follows:

- shipbuilding, aircraft construction, mechanical engineering;

- construction of railway cars;

- installation and operation of ventilated facades;

- decorative finishing of houses, buildings from the inside and outside;

- production of commercial equipment, home and office furniture;

- advertising sphere (billboards, pendants with monitors, etc.).

The most versatile industry is construction. The H-profile can be placed almost anywhere - when there is no access to the L-, S-, P-, S-, F-shaped elements, and there is a lot of the H-profile, the plan threatens to fail. The H-bar is used instead of some others - without a noticeable overexpenditure of targeted funds.

How to choose?

Focus on the load imposed on the specific dimensions of the H-shaped bar. The supporting structures of buildings, buildings and structures require at least a few millimeters of solid steel. Calculations according to SNiP and GOST show that the tonnage of the load increases nonlinearly with the wall thickness, for this it is enough to check the data in the table of values of permissible load of different thickness. If 5 mm steel can withstand, for example, 350 kg, this does not mean that 10 mm steel can hold exactly 700: the value will be in the region of a ton.

Do not skimp on the thickness of the walls and the variety of material from which they are made: the capital structure will warp and crack over time - up to a complete collapse on your head (and your neighbors).

For the manufacture of furniture, mainly thin-walled (1-3 mm) steel and 1-6 mm aluminum are used. Too thin an H-bar will bend under a person (or several persons) of a dense or full build, therefore, the thickness of the steel is taken with a small margin.

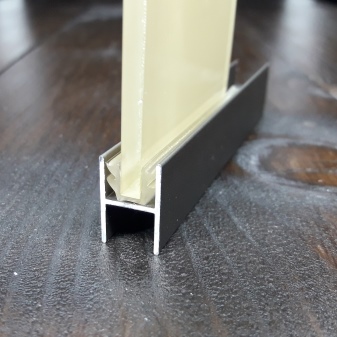

Glass in the window is unlikely to create a load on the window sill weighing more than several tens of kilograms. Window and door structures (except for the bearing support in the upper part of the opening) do not require higher than average metal or alloy thickness.

Curtains and curtains - even the heaviest ones, weighing more than 10 kg when folded - will not lead to noticeable distortion of the aluminum or steel eaves. The fact is that the curtain, together with the C-shaped profile and pendants, installed on the H- or P-structure, is weighed evenly. Even if you move the entire curtain to one edge, the load will have to be applied only to L- or U-shaped hangers or a bracket that holds all this on the wall in a horizontal position. The wall thickness of the H-profile is not critical here - both 1- and 3-mm cornices can be used. The gaps must be wide enough to securely hold the hanging brackets and curtain hangers.

The comment was sent successfully.