All about worktop planks

The trim strip is an important element in the construction of a worktop. Such an overlay will help maintain cleanliness and protect against moisture. There are several types of planks, and each of them has its own characteristics. Consider the characteristics of such elements, the subtleties of their choice and fastening.

Characteristic

A strip for a worktop is a product that is responsible for the aesthetic characteristics of the structure as a whole, for its visual perception. And you shouldn't separate even such an abstract, seemingly, moment as the color of the bar from the tonality of the main element. Traditionally, it is customary to spend lunch in the kitchen at a table with a white or very light profile. There is absolutely no point in challenging this old, proven practice. But there are times when only professional designers can make the right decision.

Often the color is selected taking into account the color of the lower hanging or floor cabinets. But quite often the opposite solution is practiced (with the task of a conscious contrast).

Colored countertops are not the only option: orders are regularly received for the black variety of such products.

They are prized for their visual luxury and sense of good taste. Importantly, such effects are achieved very easily and without any significant additional effort.

But it is worth thinking about the choice of this or that color later, but for now it is useful to go back a little and figure out what the design itself is. The universal sealing block is in demand already because the tabletop is continuously exposed to intense mechanical (and not only) stress. And apartments often lack the basic production length of countertops, which is 3-4 m. Of course, they are built up, but the build-up places are always subject to destruction, and this will be confirmed by any engineer and person who simply understands physics. The wall-mounted flexible profile solves the same problem as the front edge material, but its placement is slightly different, as already indicated by the name.

Views

A very important role is played by the protective bar at the dishwasher - the one that is also the sink. Thanks to it, moisture and dirt do not get inside the cut in the form of:

- drops;

- splashing;

- condensate;

- fat;

- water vapor;

- cuts of meat, vegetables.

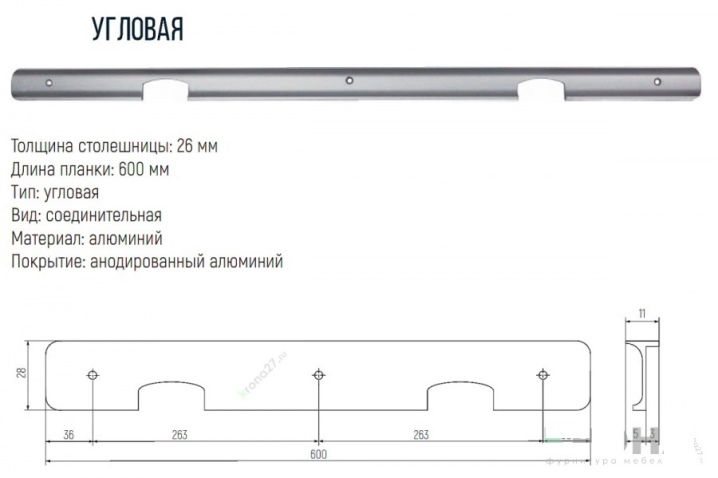

The corner model is used mainly where it is required to connect the elements of the countertop itself. Basically, such products are produced on the basis of aluminum alloys. This guarantees:

- high strength;

- easy cleaning;

- attractive decorative properties of metal surfaces;

- versatility of colors, perfectly combined with a variety of tones in the design;

- resistance to temperature fluctuations and humidity (for a steel model, such corrosion protection is difficult to achieve).

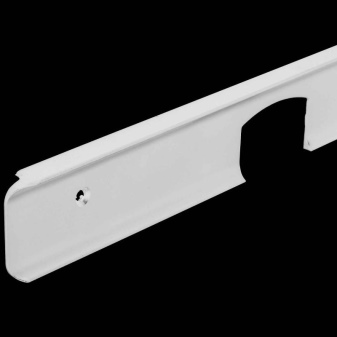

The slotted strip in most cases belongs to the already mentioned protective category. For your information: such products can also be called docking or connecting strips. There are no hard standards here. The overhead structure can play a protective role, but it must be understood that it is suitable only for straight surfaces. They also distinguish between rear and front, wide and narrow, front and side, T-shaped and U-shaped, right and left plank structures.

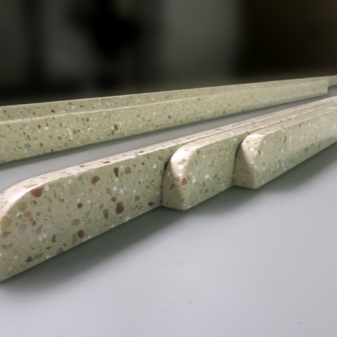

The difference may also apply to the main material. Of course, wood and ferrous metal are not used. However, the already mentioned aluminum and stainless steel have serious competitors.In some cases, the bar is improvisedly replaced with a thick silicone strip. This is a practical but not very attractive solution.

But stone products will be more beautiful and more reliable.

Dimensions (edit)

Products with a size of 38 mm are very often found on the market. Usually they are intended to connect parts of a structure. Attention: it is necessary to clarify with which specific countertops such blocks are compatible. The typical length of the planks is 600 or 800 mm. As for the width, constructions with the size can be used here:

- 26 mm;

- 28 mm;

- 40 mm.

Choice

First of all, you need to understand the type of the element. Corner strips for the kitchen (or rather, for the countertop on it) allow you to connect parts of the structure at an angle of 90 degrees. It is these products that are advised to be taken to decorate the bar counter. End structures are used to protect the ends of countertops. A clean connection (not at a right angle, but in other planes, most often in contact) is provided just by the connecting strips.

The furniture dividing block must be visually in harmony with both shared items. What is important, it is also worth considering the features of its attachment to them, otherwise significant inconveniences may arise.

This includes both simple furniture and edging options. It is much more difficult if the plank is between the oven and the countertop or between the stove and the countertop. In such cases, you will definitely need to use metal structures.

Plastic products are too unreliable. The metal will be much stronger. If you plan not only to have lunch and dinner on the tabletop, but also to cook, use a knife, then the choice is quite obvious. However, the metal strips should also be carefully selected. Polished products will turn out to be worse than matte ones, since all scratches and rubbed places are visible on them. Otherwise, you can be guided by your own taste.

Fastening

In the overwhelming majority of cases, the installation of strips for the table top is carried out during the assembly of furniture. But sometimes people try to save money or there is a need to replace products. Then they should be installed with your own hands. For work, you will need a sealing preparation and self-tapping screws. For your information: in the absence of holes for fixing them, they are drilled independently.

The sealant is supposed to be applied around the entire perimeter of the installation. The standard installation method implies that the strip will be fastened with self-tapping screws last, when the sealant is already firmly seized. Important: left and right products should not be confused, because in this case they will look unaesthetic. Another subtlety that is often forgotten, alas, is cleaning the surface before applying the sealant.

It should be applied in a uniform and relatively thin layer.

Do not categorically close the joint between the apron and the countertop with a flexible skirting board. This approach immediately gives out very greedy people with poor aesthetic taste. The best option is to order the skirting board together with the worktop itself. If for some reason this is not possible, you should at least apply later with such an order to the same company where it was made. Then no problem can arise. There are also other options:

- mid-length skirting board (apron without apron system);

- an impromptu side from the very same apron;

- using epoxy grout;

- the use of a sealant (helps when joining products from a variety of materials).

The end of the plank often has to be refined. This results in the removal of the stiff rib. It can be very annoying afterwards. Screws and self-tapping screws should be screwed in carefully, but all the way. If this is not possible, you will have to enlarge the hole or change the hardware.

The comment was sent successfully.