Washing machine brushes: characteristics, selection and repair

Today we will talk about why you need brushes for a washing machine. You will find out where they are, what are the main signs of wear and how the carbon brushes in the electric motor are replaced.

Description

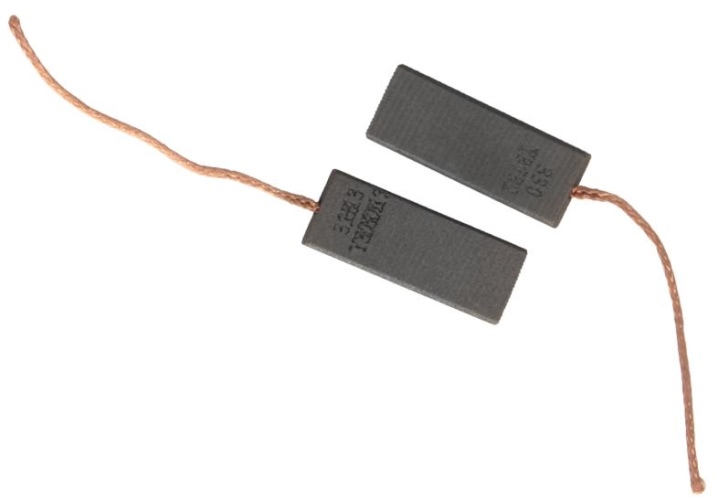

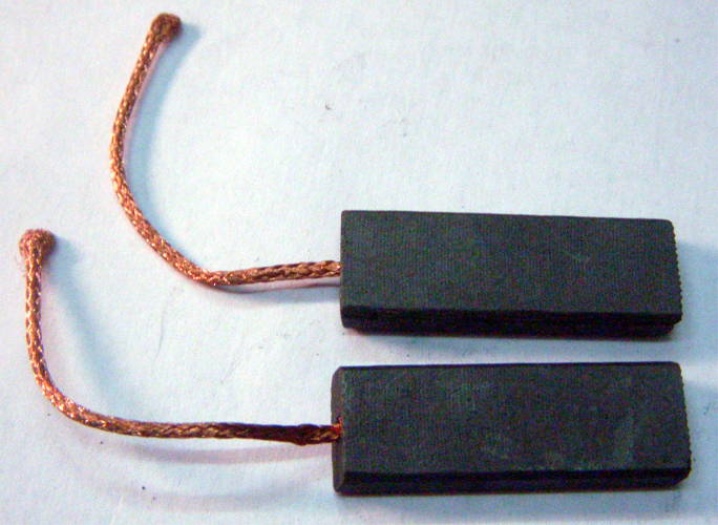

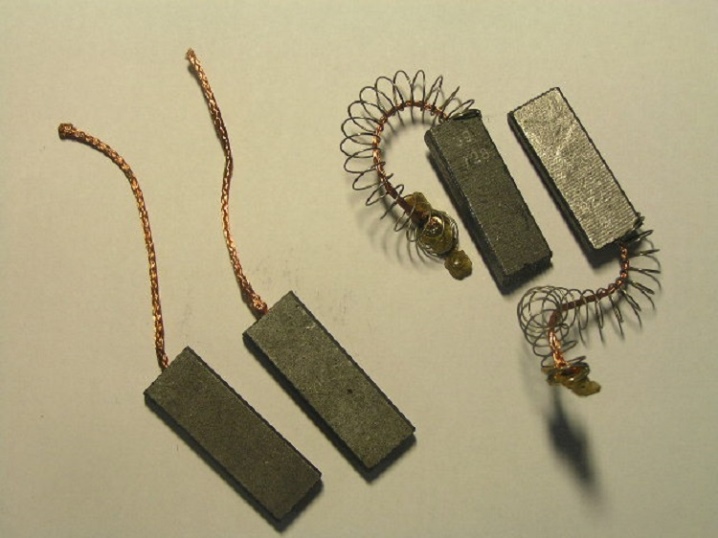

The brush of a DC motor looks like a small rectangle or cylinder made of graphite. A supply wire is pressed into it, ending with a copper lug for connection.

The motor uses 2 brushes... They are inserted into brush holders, which are made of metal or plastic. Steel springs are used to press the brushes to the collector, and the entire unit is fixed to the electric motor.

Appointment

The rotor must be energized to operate the DC motor. Graphite is a good conductor. In addition, it has lubricating properties. Therefore, bars made from this material are well suited to provide sliding contact.

Washing machine brushes, which are made of graphite, and are needed to transfer current to the rotating armature of the motor.

They provide reliable contact with the collector and serve for a long time. When connecting them, you must observe the polarityotherwise the engine will start to rotate in the opposite direction.

Views

Despite similar configurations and sizes, the brushes differ from each other. The main difference between them is the material from which they are made.

Graphite

The simplest, they are also called coal. They are made of pure graphite and have a low price. They have an optimal cost-resource balance and are therefore the most common. Their service life - 5-10 years, and it depends on the frequency of using the machine and its load during operation.

Copper-graphite

They contain copper inclusions. In addition to copper, tin can also be added to them.

The advantages are long service life and high strength, which increases the resource of the collector. The disadvantage is that it takes more time to break in.

Electrographite or electrobrushes

They differ from coal in the manufacturing method. They are produced by high-temperature treatment of a mixture of carbon powder, binder and catalytic additives. A homogeneous composition is formed.

Advantages - high electrical conductivity, low coefficient of friction and long service life.

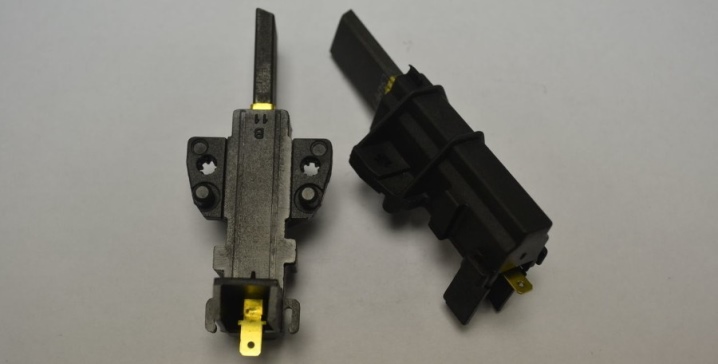

Top brushes are equipped with a shooting system that automatically shuts off the engine when the rod is worn out.

A spring with an insulating tip is embedded inside the rod. When the working length reaches the smallest limit, the spring is released and pushes the tip onto the manifold. The electrical circuit is opened and the motor stops.

Where are they located?

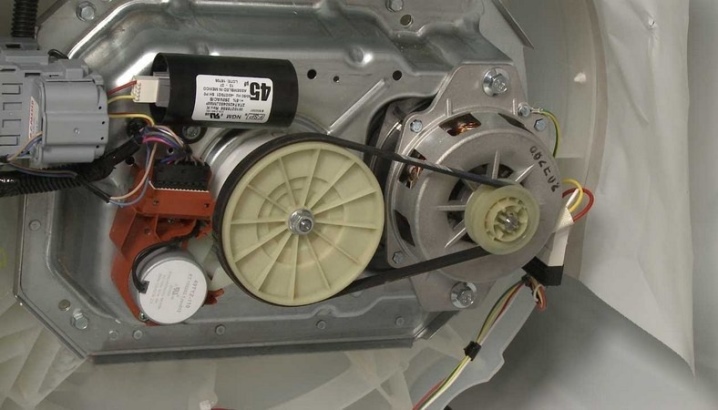

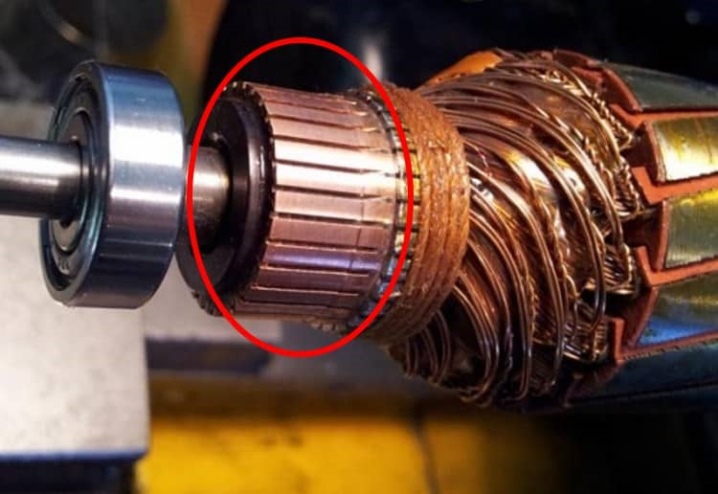

The brush holders are located on the collector side, that is, opposite the output shaft. They are usually located on the sides of the motor housing and are located opposite each other.

They are attached to the stator with screws. In addition, large cross-section power cables go to the brushes. So it won't be difficult to find them.

Causes and symptoms of malfunction

Like any moving part, the described part is subject to wear. In this case, the problem manifests itself in different ways.

Here are the most common signs:

- the power of the electric motor has decreased, it may not pick up speed and stop at any time;

- there is extraneous noise, crackling or squeak;

- poor spinning of laundry;

- the smell of burning, burning rubber or plastic;

- the engine sparks noticeably;

- the machine does not turn on, an error code is displayed during self-diagnosis.

When such symptoms appear, you must immediately disconnect the machine from the network and do not use it until repair. Neglect threatens with serious damage, up to the complete failure of the engine and control board.

It is necessary to change the graphite rodswhen their working length is less than 1/3 of the original. That is when they have worn down to 7 mm... You can check the wear with a ruler, but for this they need to be removed.

In general, brushes are consumables. They are constantly being erased, so their failure is a matter of time. But their cost is also small. The main thing is to choose and install the right spare part correctly.

Selection of brushes

To reduce the cost of production, firms usually put the same engines on different washing machines. This unification aids in repairs as it reduces the inventory of spare parts.

When choosing in a store, it is enough to say the model of the car, and the seller will select the desired part. Marking will help you, which must be applied to one of the sides. The dimensions are indicated on it. You can take a sample with you as a guarantee.

The material of the brushes has almost no effect on the performance of the motor. It only affects the frequency of their replacement. Therefore, when choosing, decide how often you are ready to make repairs.

It is advisable to buy products from well-known manufacturers. Here is a list of the best firms:

- Bosch;

- Whirpool;

- Zanussi;

- Beko.

But in general, it is advisable to take brushes of the same company that made your machine... The quality of original parts is generally higher. But sometimes brushes from one manufacturer may be suitable for another manufacturer's washing machine. For example, Indesit L C00194594 carbon contact can be installed on most Indesit engines as well as Bosch, Samsung or Zanussi. Take advantage of this.

For sale universal brushes that are suitable for different models of machines. They are produced by little-known companies, so their quality is unpredictable.

Please inspect them carefully before purchasing. If you're lucky, you can save a lot. And if not, then start a new repair after a few washings.

Here are some general tips.

- The main thing when choosing brushes is dimensions... It is they who determine whether it is possible to put a graphite bar in the brush holder.

- The kit includes 2 brushes, and they change at the same timeeven if only one is worn out. This is necessary to evenly press them against the manifold and extend the life of the engine.

- Examine the part carefully. Even small cracks and chips are unacceptable... Otherwise, during work, it will quickly collapse. The surface must be smooth and matt.

- Buy spare parts only in specialized stores household appliances. There, the probability of a fake is minimal.

- Many services cooperate with manufacturers. You can order the parts you want from them and in addition to receive detailed advice on repair.

Choose details carefully, even if the master changes them. You will still be using it.

Replacement and repair

When the brushes wear out, they need to be replaced. Such work is within the power of anyone who knows how to hold a screwdriver in their hands. And although washing machines and electric motors differ from each other, the sequence of repairs is the same for them.

The main thing is to observe safety precautions.

First, you need to prepare the machine.

- Disconnect it from the network.

- Close the water inlet valve.

- Drain the remaining water from the tank. To do this, unscrew the inlet pipe. Attention! Water may start to flow abruptly.

- Remove the lower bezel, remove the drain filter and drain the remaining water through the emergency hose. You can also clean the filter at the same time.

- Position the clipper so that it is comfortable for you to work.

After that, you can proceed to removing the engine.

- Remove the back cover. It is fastened with screws.

- Remove the drive belt.To do this, slightly pull it towards you and at the same time turn the pulley counterclockwise (if your machine does not have a direct drive).

- Take pictures of the location and connection of all wires. Then disable them.

- Examine the engine. Perhaps, without dismantling it, there is access to the brushes.

- If not, unscrew the motor mounting bolts and remove it.

Next, we go directly to the replacement.

- Unscrew the fastening bolts of the brush holder and remove it.

- Decide what you will change - just the brushes or the complete brush holder. In any case, choose carbon rods carefully.

- Remove the brush from the nest. Pay attention to the direction of the sharpening. Note that the contact wires are soldered to the brush holders.

- Install a new part. The direction of the bevel on the brush should provide the largest contact area with the collector. If this does not work, rotate it 180 degrees.

- Repeat the procedure for the other carbon contact.

If your machine is equipped with a direct drive, the procedure is slightly different.

- Remove the back cover.

- Dismantle the rotor if necessary. This is necessary for easy access to the brush holders.

- Replacing the brushes is the same. Observe the direction of sharpening.

Service the manifold before installing new parts.

Wipe it with a cotton swab dipped in alcohol. This is necessary to clean it from carbon deposits and coal-copper dust. If rubbing alcohol doesn't work, sand it down with fine sandpaper. After all work, the manifold must be clean and shiny. Scratches are not allowed on it.

After installing new parts, rotate the motor shaft by hand. The rotation should be smooth and light.

Then assemble the washing machine in reverse order and connect it to all necessary systems.

When turned on for the first time, the machine will crackle. This means that you did everything right. An extraneous sound is caused by the running-in of new brushes. To ensure that they rub in normally, run the machine at idle in a gentle wash. And after a while of work, smoothly increase the speed, up to maximum.

To begin with, it is not recommended to fully load the machine. This is not for long, after 10-15 washes it will be able to work normally.

It is impossible to fully load the machine during running-in, not to mention overloading.

If the clicks do not stop for a long time, you need to inspect the engine. This time it is better to call a specialist.

You will learn how to change the brushes in the washing machine below.

The comment was sent successfully.