Repair of Hotpoint-Ariston washing machines at home

Often, owners of Hotpoint-Ariston washing machines are faced with the need to repair their household appliances. In some situations, for one reason or another, they have to perform certain work at home. With the right knowledge, skills and tools, this can help reduce operating costs.

Design features of Hotpoint-Ariston washing machines

Before performing repairs of any complexity, it is recommended that you familiarize yourself with the features of the device and the functioning of the equipment. Front-loading machines are more popular these days, on which basis it is worth considering their design. The main components and assemblies of such models include the following:

- frame;

- Electrical engine;

- drum and loading door;

- pumps that fill the LM tank with water and ensure its drain;

- a control system responsible for the selection of washing modes and changing parameters;

- sensors and valves of the Waterproof-System (WPS) system, which provides effective protection of equipment against leaks;

- pressure switch sensor and valve (WCS) - a device responsible for monitoring the water level in the tank of the machine;

- shock absorbers, suspension springs and counterweights, damping vibrations of the device during washing and spinning;

- an imbalance sensor that corrects the rotation of the drum to evenly distribute the laundry;

- a siphon that acts as a water seal for the drain hose;

- ball valve type drain hose;

- drain filter.

Naturally, this list will depend on the model of the washing machine and its configuration.

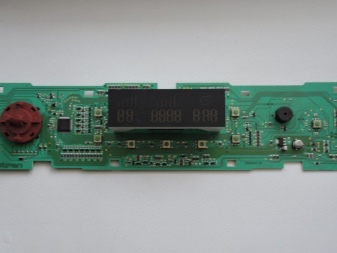

Error codes

Promptly check the technical condition of the washing machine and troubleshoot the error messages and malfunctions help. In models equipped with displays, they are displayed on it in the form of the corresponding symbols.

Let's take a closer look at the following error codes for Hotpoint-Ariston machines and their corresponding malfunctions:

- F01 - short circuit of the electric motor circuit;

- F02 - failure or failure of the tachometer;

- F03 - problems with the temperature sensor;

- F04 - the pressure switch is out of order - a device responsible for controlling the water level;

- F05 - problems with water drainage; breakdown of the pump or level sensor;

- F06 - problems with control buttons (refers to the Dalogic model series) or failure of the hatch locking mechanism;

- F07 - heating element without water, which is caused by problems with the pressure switch;

- F08 - giving a signal to activate heating when the tank is empty, indicating a "sticking" of the pressure switch;

- F09 - problems associated with the memory of the washing machine;

- F10 - no signal about the water level in the tank;

- F11 - lack of reaction of the pump to the commands of the control module;

- F12 - lack of communication between display and control systems;

- F13 - error of the drying temperature sensor;

- F14 - failure of the drying heating element;

- F15 - drying of laundry is not activated;

- F16 - failure in the process of automatic parking of the drum (relevant for models with top loading);

- F17 - hatch door in open position;

- F18 - microprocessor failure;

- F20 - problems with water intake.

Important! An error reporting system is also provided for Hotpoint-Ariston models without displays. In this case, we are talking about the combinations and frequency of blinking of indicators.

Required tools and spare parts

For self-repair and maintenance of the washing machine, you will need not only knowledge and practical skills, but also the appropriate tools and accessories. In the first case, we are talking about the following devices and devices:

- a set of screwdrivers of different shapes and sizes;

- a set of wrenches (most often open-end), in which keys 8/9 and 18/19 must be present;

- nippers, pliers and platypuses (preferably some with curved and others with straight jaws);

- pliers for self-clamping clamps;

- long tweezers;

- multimeter.

Naturally, this is an incomplete list of tools that are suitable for diagnosing and repairing SM. In each case, the list will change... In addition to all of the above, it is recommended to take care of the presence of a flashlight. The best option would be the so-called forehead. In addition to tools, you may need spare parts.

Depending on the malfunction, we can talk about a wider list of components. It includes electric motor brushes, belt, valves, filters, hoses, and sometimes drum blades and much more.

How to replace the sunroof cuff?

Initially, it should be noted that the sealing rubber is attached to the tank and the front wall of the device with clamps. In a simplified version, the whole process is reduced to to remove them from the damaged cuff and install on a new one. At the preparatory stage, it is necessary to disconnect the machine from the network and turn off the water supply. After that, the hatch door opens.

The next step is to remove the outer clamp. If it is plastic, then it will be enough to pull on the elastic band at the junction of the latches. And also the clamp can be fixed with a screw that needs to be loosened. In other cases, it is necessary to pry the spring with a screwdriver.

It is important to take into account that there is a mark at the top of the cuff that is aligned with the mark on the tank. In the absence of the latter, it must be applied with a marker before dismantling.

Removing the inner clamp involves the following steps:

- dismantling the top cover of the machine;

- removing the front cover (for models in which the first manipulation will not provide access to the clamp);

- unscrewing the tightening screw;

- prying off the spring and tightening the clamp.

After the above steps are completed, it is required to clean the seats and install a new cuff. To do this, follow these steps:

- thoroughly wash off the dirt using detergents;

- apply a soapy solution to the mounting places for better gliding;

- align the marks on the tank and the new rubber band;

- pull the cuff over the edges, making sure it fits snugly;

- install an internal clamp;

- use an external clamp to securely fasten the collar to the machine body.

At the final stage, it remains only to replace the front panel and the top cover. After all the actions, you can connect the device and test.

What if it doesn't turn on?

As practice shows, such problems arise for the following reasons:

- lack of power due to a defective outlet or plug, as well as damage to the cord;

- failure of the control module.

In the first case, the repair will be as simple as possible and will require little time. And here It is better to entrust the solution of problems with the control unit of Hotpoint-Ariston washing machines to specialists.

Sometimes, after turning on the CM in the network, an indication appears indicating readiness for work. However, after selecting a mode, the washing process is not activated. This may be the result of a clogged filling unit or engine breakdown.

How to remove the blockage?

If, after the end of the wash cycle, the pump is activated, but the water does not leave, then we are most likely talking about a blockage in the line. They can form in the following locations:

- drain filter (most often it is this element that causes the malfunction);

- a branch pipe between the filter and the tank;

- water pump (pump);

- the drain hose itself.

It is recommended to start performing work aimed at eliminating blockages from the most accessible places. To do this, follow these steps:

- open the plinth panel;

- unscrew the filter;

- remove all accumulated debris;

- install the filter in place;

- put the washing machine on its side;

- loosen the clamps and remove the branch pipe;

- inspect the pump - if necessary, disassemble the pump and clean it thoroughly.

Dismantling and installation of a new pump can be done independently. But with the slightest doubts about your own abilities, it would be most rational to seek qualified help.

At the final stage, you will need to inspect the drain hose for blockages. An ordinary plumbing cable will help to solve the problem. However, it should be borne in mind that these hoses rarely become clogged.

How do I drain the water?

Regardless of the features of the Hotpoint-Ariston CM model and its design there are 5 ways to forcibly drain the tank... In this case, you will need a minimum set of tools and tools at hand. Their list includes a flat screwdriver or knife, a basin and a doormat.

Method number 1

The first option for draining water involves using a drain hose. In this case, the algorithm of actions will be as follows:

- disconnect the hose from the sewer pipe or siphon and release it from the fastening clamps, if any on the body;

- lower the end of the hose into the basin;

- drainage of water by gravity.

Method number 2

It is produced through the drain filter of the machine. To do this, you will need to take the following steps:

- remove the bottom panel, which can be picked up with a flat screwdriver or an ordinary knife;

- tilt the automatic machine and support it on the wall so that the basin is located under it; such actions should be performed with caution and preferably not alone;

- Partially unscrew the filter and drain the water.

Most often, with this method, you inevitably have to collect spilled and splashed water from the floor. It is for these purposes that it will come in handy a rag prepared in advance.

Method number 3

The third method allows you to get rid of water forcibly using an emergency drain hose. In this case it is important to take into account that its presence is not provided for by the design of all models of washing machines. If one is still present, then you should look for it next to the drain filter under the decorative cover of the bottom panel of the device. After removing or opening the cover, you will need to carefully pull out the hose and remove the plug from it. Then the free end of the tube is placed in a basin and the water is drained.

It is worth considering that its diameter is not very large and the whole process will require a certain amount of time. At the same time, you don't have to worry about wiping up puddles on the floor.

Method number 4

Option # 4 involves removing water through the SM hatch. If the methods described above did not help to achieve the desired result, then you can try to trivially scoop up the water. In this case, two important points should be taken into account, namely:

- in situations where water can be seen through the hatch window, the machine should be tilted away from you, leaning it against the wallotherwise, when the hatch is opened, water will simply spill out onto the floor;

- any convenient dishes or utensils can be used to scoop out; it can be either a large mug or a ladle.

Method number 5

The last fifth method is to use a drain pipe. The procedure in this case will be as follows:

- remove the back wall of the CM to gain access to the branch pipe located under the drum;

- place rags and a basin directly under the nozzle;

- remove the clamp and disconnect the branch pipe from the pump;

- if necessary, remove the blockage if water has not poured into the basin; you can do this with any convenient tool or just with your fingers.

The main disadvantage of this method is its complexity. However, having performed the listed manipulations, you can be guaranteed to empty the tank of the machine. By the way, in some cases the reason for stopping the wash can be eliminated in parallel.

Other typical faults and how to fix them

As noted above, the list of problems that arise in the process of even the most reliable washing machines is quite long. Moreover, some of them can be solved at home with your own hands. It is important to remember that each repair should be approached with the utmost responsibility so as not to aggravate the situation. Often you have to deal with a faulty water intake valve, which does not shut off the water, it enters the tank itself. This happens even if the CM is disconnected from the network. It is very easy to identify this malfunction by the sound of a gathering tank when the equipment is turned off.

The object of repair is located in the upper part of the machine, namely, at the point where the inlet hose is connected. First of all, it is recommended to carefully inspect the gaskets. After that, it will be necessary to use a multimeter and measure the resistance by installing the probe probes of the sensor contacts. With a working device, the value should vary between 30-50 ohms. The defective part must only be replaced.

Another of the most common problems is failure of the heating element. The heating element most often breaks down due to hard water and the formation of scale. In the event of such a malfunction, washing will be carried out in cold water, or the CM will not react at all to the positions of the program switch. For diagnostics and repair, you will need to perform the following steps:

- disconnect the Hotpoint-Ariston machine from the power supply and other communications;

- remove the back panel;

- use a multimeter to check the resistance at the contacts of the heating element; if it is serviceable, then the device should show from 25 to 30 ohms; with a short circuit, the resistance will be zero, and an open circuit will be indicated by a resistance value of 1 Ohm;

- unscrew the mounting bolt, disconnect the wiring and remove the heating element;

- install a new element by doing all the steps in reverse order.

Often, the owners of SM Ariston have to deal with such an unpleasant moment as failure of the control unit. This is most often due to sudden power surges. The use of stabilizers or, at least, a surge protector will prevent the negative consequences of such fluctuations. In such cases, it is best to entrust repairs to professionals. You can only replace a failed board with a similar new one on your own.

Continuing the list of common faults, it should be mentioned bearing problems. In such situations, one has to deal with one of the weak points of this brand of washing machines. These are non-separable tanks. It seems that the manufacturer deliberately made the process of replacing bearings as difficult as possible.

However, as you know, nothing is impossible, and the craftsmen found a way out of the situation. The procedure is as follows:

- equipment is de-energized and disconnected from communications;

- the tank is dismantled;

- the edge of the metal tank is flared with a gas burner;

- plastic tanks are sawn at the seam.

Of course, the list of possible problems is not limited to the above breakdowns. Unfortunately, owners of even the most expensive and reliable models are not insured against the need for repairs. For example, sometimes the machine door may stop closing tightly... In such situations, it will be necessary to establish the specific cause of the breakdown. Based on the diagnostic results, it will be necessary to do the following:

- tighten the hatch hinges;

- replace the retainer;

- check, service or replace the lock with a new one.

One of the most significant malfunctions is failure of the electric motor. In some cases, the repair can be reduced to replacing the brushes. To do this, you need to do the following:

- put the CM on one side;

- dismantle the engine;

- replace brushes;

- thoroughly clean the collector, as well as the space between it and the lamellas.

Repair Tips

The key point is the complexity of many renovations. With a lack of knowledge and experience, doing repairs with your own hands, you can only worsen the condition of the machine. As a result, the costs of correcting the situation will increase significantly. Self-elimination of malfunctions in the overwhelming majority of cases involves replacing failed elements with new ones. These include the following:

- drive belt;

- water pump;

- temperature sensors;

- branch pipes;

- filter elements;

- Heating element;

- Control block.

Naturally, you can remove blockages yourself. All listed works do not require deep special knowledge and skills. If you identify more serious problems, you should contact the service center for help. Otherwise, the risk of encountering more significant breakdowns increases, the elimination of which will require considerable financial and time costs.

Next, watch the video on replacing the bearing of the Hotpoint-Ariston washing machine.

The comment was sent successfully.