Description of key cutting machines and their selection

Key sharpening is a promising and profitable business. This explains the wide range of equipment used by different enterprises. From the material in this article, you will learn what kind of key cutting machines are and how to choose them correctly.

general description

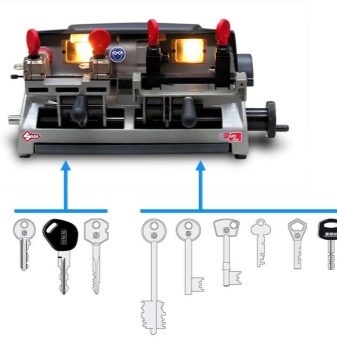

Key duplicate machines - units with different settings and levels of automation. They differ in strength, most of the models function by using a copy unit.

The key structural elements are cutters, copy unit, work table. Final processing of keys is carried out at the expense of needle files, a tuning block, a device for measuring the accuracy of the made copy.

The copy unit of the duplicate milling machine is equipped with a probe. Thanks to him, it is possible to make exact copies. With its help, a duplicate is removed from the original and transferred to the workpiece.

The trajectory of the table movement differs depending on the product modification. It can move not only along the axis of the installation, but also across it.

Equipment for the production of duplicate keys is considered a specific and highly specialized desktop-type technique. He has a high resource, small size, different type of construction, quick payback.

What are they?

Key cutting machines are very diverse. They have different technical characteristics, sizes, functionality. They are designed for the production of different types of keys. The procedure takes a minimum of time and is performed with the highest copy quality.

On sale there are varieties for the manufacture of flat, rounded, cruciform keys, modifications with grooves.

Also, the installations are designed for copying English, pump, rod, Finnish, rack and pinion (crossbar) keys.

In addition, the products can have perforations on the surface in the form of dotted depressions of the same size. Others accurately copy the lateral vertical milling.

By type of work there are vertical and horizontal milling. Vertical adjustment involves the creation of indentations on a flat workpiece (surface of the working part). Horizontal adjustment is needed for cutting furrows (one, two). Furrows are formed on the end faces.

Vertical installations are easier. They are designed for making keys with a wave or a worm. Universal analogs are classified as professional equipment.

They are suitable for working with various types of blanks (safes, doors, car keys). In addition to vertical, universal equipment, there are duplicators of intercom keys on sale.

The equipment differs in the number of working cutters, which varies from one to several. Variants of the second type are used for simultaneous work with several surfaces.

By the type of work, the installations can be traditional and with software. Options of the second type assume automatic adjustment of corner and side mills.

Their vice is able to hold workpieces at any angle. In this case, the vice itself can be ordinary and 4-sided. Thanks to this, it is possible to reproduce complex shapes and restore broken keys.

Popular manufacturers

Different brands are engaged in the production of key sharpening machines.

Turkish

Turkey's equipment is distinguished by its ease of use and build quality. A classic example is the Kurt universal machine. Has a smoothly sliding built-in carriage and linear bearings.

Copies different types of keys perfectly. Equipped with a pair of vices that securely hold the workpiece during processing. Clones different keys, including models for cars with chip cards.

A decent option - Advanced code Evo with electronic control. Duplicates chip keys well without connecting to a computer for chip recognition.

Provides online update of the program associated with the production of new key modifications. Provided with instructions with clear explanation of startup and operation.

For duplicates in the form of corners and holes, the Matrix device with 2 speeds of the electric motor has been developed. It has steel cutting edges, triple workpiece direction and built-in illumination.

Chinese

Duplicators of Chinese suppliers stand out for their good options. Some models are able to duplicate Finnish, English, pump, laser keys. Almost any product can be copied onto them.

One of the popular models is the Wenxing, equipped with 2 cutters, a rotary vise and a smooth running system of the carriage. It provides for a reliable fastening of the key while making a copy.

Chinese machines are distinguished by the best price-quality ratio. Most of the workshops in our country work for them. This equipment is supplied with an instruction manual and a training disc.

It is suitable for copying not only one-, but also two-sided duplicates, including copies for various types of vehicles. It can sharpen keys for garages and safes, cross-shaped and transom copies.

OSKAR 2009-A is an analogue of the well-known Wenxing-100F. Designed to create copies of flat, car, apartment, tablet, cross, lever type.

Has 2 modes of speed of milling rotation and two-plane setting of copiers. Equipped with an element for Finnish keys, table lighting and a brush for finishing the workpiece.

Italian

Among the demanded models, there are products of Italian brands. For example, the best product of the Silca brand is the Duo Plus. The universal machine can copy a wide variety of key types. It reproduces high-precision copies, has software control and updates the base as needed.

The company produces an installation for intercom duplicates of contact and contactless type.

The machine quickly reads information, loading it onto workpieces of various shapes. The whole process takes no more than 2 minutes.

A duplicator Matrix SX with a milling type of work is in demand among buyers. The installation belongs to the category of universal ones, since all known types of keys can be copied on it.

The adjustment of the cutting edges takes place without operator intervention. All that is required of him is to enter the program and fix the part. Thanks to the integrated vice, the workpiece can be machined at any angle.

The machine has 2 speeds, there is a protection screen and an option for lighting the desktop. In addition, additional equipment is provided in the form of cutters for other processing of duplicates.

Criterias of choice

To choose the right equipment for key duplication, you need to take into account a number of nuances. Initially, you should decide on the type of keys that you plan to copy.

For example, The universal type is suitable for creating duplicates of any shape with the vertical position of the cutting mills. Such equipment can be used to make magnetic keys for intercoms.

Vertical options are highly specialized. Only one type of keys is produced on such equipment. In this regard, vertical counterparts are considered the best. They are equipped with fixing devices and various combinations of available cutters.

Price is not the main purchase criterion. The question of saving in this case is inappropriate, since high-quality equipment will bring decent profits.

It is more important to pay attention to the technical characteristics and performance of the installation. The determining factor is the accuracy of copying and the level of automation of the process.

The selected model must be universal. Using a set of cutters, the operator will be able to produce different types of keys, including car chip cards and intercoms.

An important characteristic is the smoothness of the moving carriage. This is necessary for the proper performance of the work during the cutting and furrowing of the workpieces.

The presence of a backlight will contribute to a better operator's work. Thanks to the optimal level of illumination of the desktop, the quality of the products will increase.

High-quality equipment is equipped with a factory vice. This contributes to a secure clamping of the part while copying the key.

In order for the technique to reproduce flawless duplicates, you need to choose a model equipped with a grinding disc device. This will eliminate the need for manual revision of the duplicate.

The ideal option is an automatic machine with programmed control. Almost all of his work is done without operator intervention. The only thing that is needed is to set up the CNC and fix the future duplicate on the desktop. The CNC module automates the process, although it affects the cost of the installation.

You need to choose the right supplier. In order not to regret the choice, you should give preference to a brand with a good reputation in its segment.

Consideration should be given to the amount of work, needs and goals. For a small business, it is enough to purchase a household option. Business needs a professional universal machine.

On sale there are varieties that work from the supplied power supply. Advanced machines work with a computer after entering a database with a detailed description of the types of copies.

Someone prefers to purchase models with visualization. These machines have built-in displays that show the process of copying the chip.

Other modifications have independent memory for a specific number of codes. Due to this, a database is created into which information can be entered and subsequently used to recover lost keys.

As for domestic models, in comparison with analogues of other countries, they are highly specialized. Despite the reliability and quality, some have a limited range of options.

It should be borne in mind that certain varieties can only copy the keys of specific manufacturers. Buying such options is not always justified. You need to take those machines that are suitable for copying common keys.

When selecting an option from a specific supplier, along with the machine, an initial set of blanks is selected. The sets differ in the number of elements and their varieties.

Some models are equipped with special copier attachments for non-standard originals. In addition, when choosing a particular installation, they pay attention to the possibility of purchasing consumables (cutters, belts, brushes).

Nuances of operation

It is not difficult to make a key on a machine. This requires the original key. The operator draws out its contours. After that, a workpiece is placed on the machine, clamped in a vice and a copy is cut out.

At the final stage, the copy is polished. However, in order to improve copy accuracy, presetting is performed. Moreover, it is important not only to choose the right type of workpiece correctly, but also to position it correctly in a vice.

The part is clamped in the same way as the master key to be copied. The first cut is deep. After that, the carriage is attached in such a way that movement is possible forward and backward.

This prevents the original key from sliding off the workpiece. After slitting one side, the clamp is removed.For further work, it is not needed (work does not require rigid attachment).

In fact, copy creation is divided into 2 stages: roughing and finishing. First, the excess material is cut to fit the original shape.

This is followed by cleaning with a stiff brush. It removes scale and small burrs. Then the second side of the part is washed down and its subsequent revision.

If you need to program the chip, you need the original and an empty blank tablet. Programming is performed by copying the code to the emulator. In complex protection systems, an auxiliary chip is prescribed by means of diagnostic devices of control units.

Reprogramming is performed after reading the original chip. Then they take a key with a transponder, write down the code, activate the ignition with the original, then with a duplicate.

The comment was sent successfully.