Winding machines overview

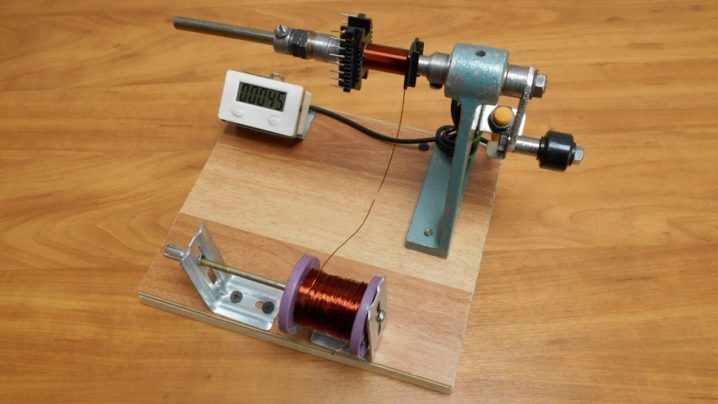

Winding machines are a separate type of equipment designed for repair, restoration or manufacture of various devices. Electronic turn counters for coil machines can be made by yourself or purchased from a specialized store.

Peculiarities

An overview of winding machines usually starts with the history of the equipment, but in fact the term "winding" can be used to refer to any device that applies a uniform layer of winding. They are divided into groups along the vertical and horizontal axis of rotation, the scope of application. They are used in the electronics industry, in the manufacture of electrical equipment. The winding machine can be used both in the construction and in the weaving industry (for folding finished products into rolls).

Winding machines are a large group of special equipment used in the most variable industries. Developers (domestic and foreign specialists) used different dimensions and principles, creating machines for urgent needs. In doing so, they focused on priorities and specific needs. Electronic equipment is one of the main consumers, since winding works in it make up a significant percentage of the total number of processes: conductive turns are laid on nodes where windings are needed, on tubes, tapes and other parts with a variable configuration.

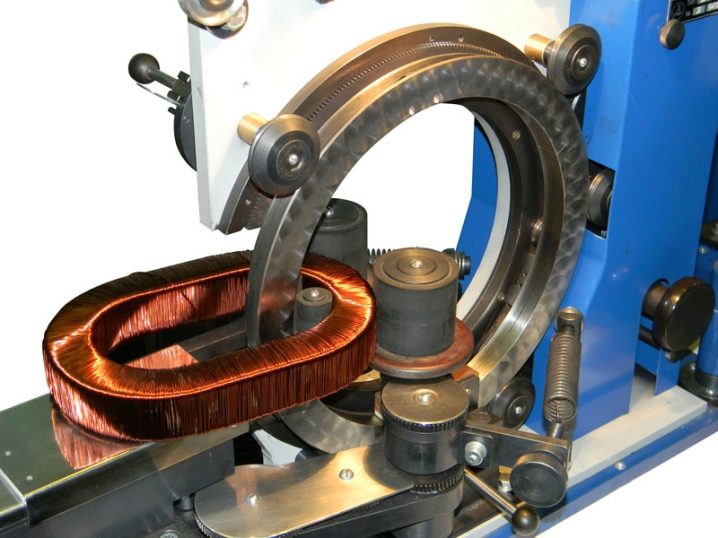

The windings can be single-layer or multi-layer. The former are divided into toroidal, cross and ordinary, but these are also not homogeneous and of the same type. The turns, like the sections of the conductor, can be laid close to each other or at some equal distance.

A row is the number of turns required in a particular part, and a pitch is the distance between the centers of two adjacent turns. The width or length of the winding is the distance between the extreme rows of the completed winding.

The features of such equipment can be:

- rotation of the frame or the wound wire;

- type of wire movement (uniform, rectilinear-returnable);

- the presence of a counter for registering the number of revolutions;

- the degree of tension in different ranges;

- mechanical or non-mechanical drive.

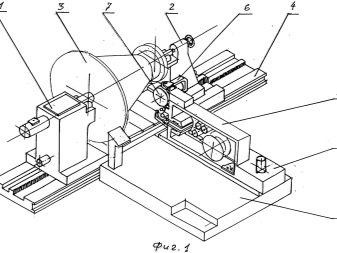

The unit itself consists of a standard set of parts. The carriage is arranged with guide rollers that distribute the material evenly along the drum. In special sources, it is certainly mentioned that the power, performance and type of energy used in devices of this type are variable and depend on the scope of use. Even the standard mechanisms have differences in size, functionality and cost, which seems reasonable.

Species overview

Manual winding machine is differentiated into several types: ordinary, universal and toroidal design options have their own characteristics, each of which is taken into account when buying or making at home. Basic types of winding are available to simple units: single-layer and similar with a pitch, multi-layer.

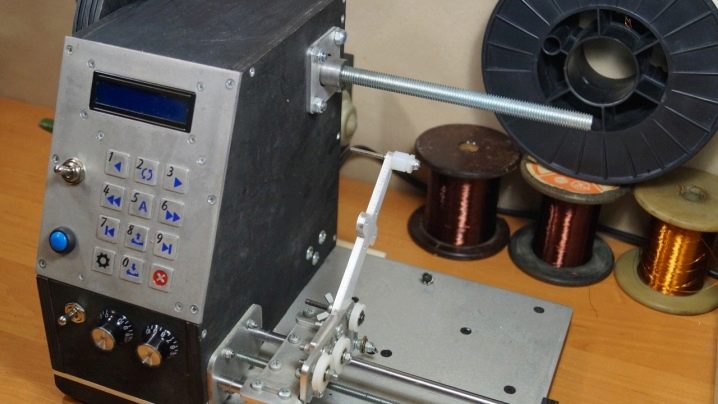

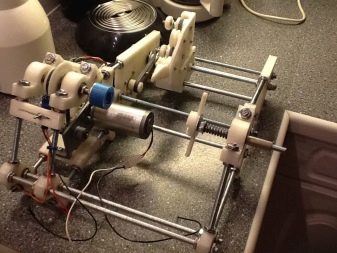

Modern machines are equipped with software control that controls not only the sequence of the process, but also its quality. To do this, it is enough just to set the unit in a certain sequence.The CNC device works independently, it only needs a dispatcher who monitors the quality of the specified program.

She herself provides all the parameters: from the tension density to the step. Such devices are not cheap and are used in mass production.

At home, you can use units made by the manufacturer or assembled by yourself. A desktop machine of any origin is convenient, compact and mobile, but it is used in a limited number of processes: mainly for the repair and restoration of parts, if they are required permanently, and buying new ones is financially difficult. They are used for ordinary winding, single or multi-layer, for transformer coils. The cable winder, like any other equipment for this process, is mechanical (the winding is set by rotating the handle or pressing the pedal) and automatic, using energy that is transferred to the intermediate shaft, imparting rotation to it using a transmission and pulleys.

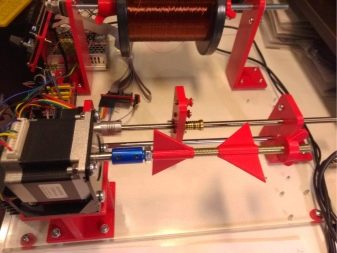

The main types are transformer winders for electric motors, machine tools SRN and SNS on a stepper motor.

Any of them can be with an auto-stacker, other nuances of technological equipment, perform various types of winding, use wires of variable diameter.

Transformer winders

A special simple and functional device that will come in handy for any equipment repairman or home craftsman. Its useful feature is the ability to repair a burnt-out transformer without much difficulty. This is valuable when the required type is not on sale, and the manufacturing plant does not deal with one-time deliveries of spare parts.

The machine is designed for winding wires on frames with an inner diameter from 1 to 19 cm. Not all machines are designed for such a run in diameters, they have varieties, and at this point you need to pay attention when buying. The second feature is manual or semi-automatic operation. Good products in the kit certainly have replaceable pulleys that provide the desired winding step. The machine does not require attachment to the table top, because it weighs a lot. The combination of pulleys will provide a huge variety of winding steps. No special knowledge is required to operate such a unit.

NRC

An excellent functional option for performing ordinary winding. The sectional winding machine winds open-type wire onto not only round frames, but also rectangular ones. The wire can be from 0.5 to 0.05 mm in diameter. The model is expensive, but domestic manufacturers have minimized the cost, and some companies even deliver units at the expense of the buyer to any region of the Russian Federation. This is a nice bonus, since the dimensions are significant and the weight is over 80 kg.

SNS

The machine is useful when performing ordinary winding, it has great accuracy and speed, good technical equipment. Works with wires for electrical engineering with a diameter of 3 to 0.01 mm. Other popular types are available to him: stepped, pyramidal, conical and even orthocyclic winding. Works with high and low voltage coils, uses variable pitch.

There are models with control performed by an electronic module, smooth speed control and an increase in the length of the turns up to a meter. Some manufacturers offer the option of replacing elements. This is an expensive equipment that will justify every penny invested.

On a stepper motor

Compact and mobile, high performance. The simplicity of the device will allow it to be used even by an employee without special knowledge. Reliable, powered by a household network, used to make transformer and choke coils with a wire diameter of 0.6 to 0.1 mm.

Popular models

The consumer can choose any of the listed devices, but an Italian or German machine with advanced functionality will require more significant investments. Domestic models are distinguished by their durability, affordable price and functionality. From those demanded by buyers, you can list:

- SNS-1.5-300 "Quasar" with a modifier and an electronic module, without a noisy mechanical transmission;

- SNS-1.0-100 (150) with open horizontal winding and CNC;

- made by hand on the recommendation of folk craftsmen who post videos and instructions for making on the Internet.

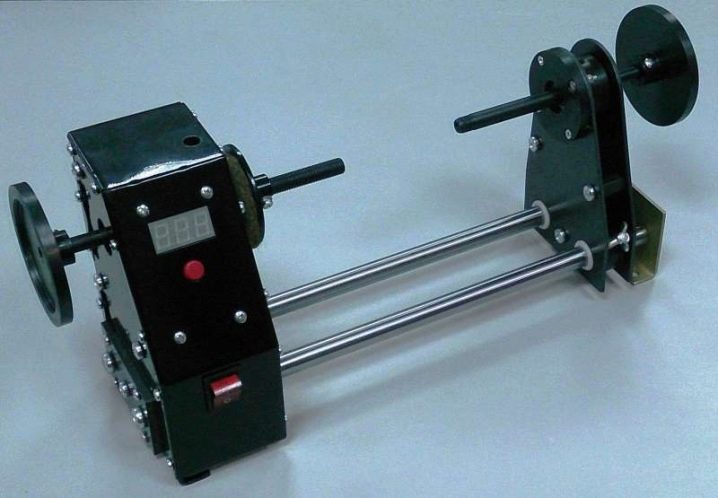

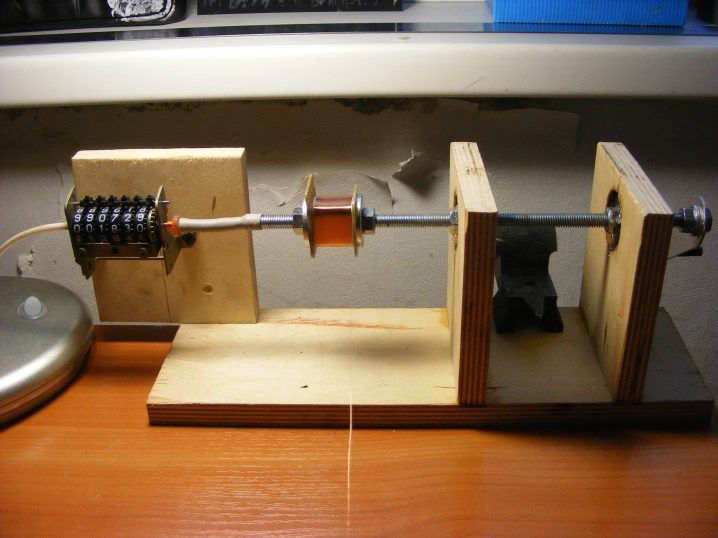

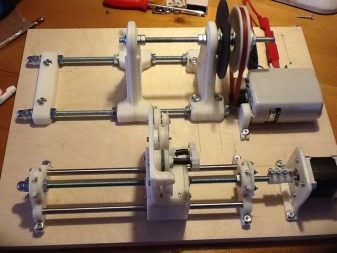

An example of the latter is such a device.

To make the right choice, you can analyze the frequency of use and the nature of the work performed, and then compare prices for the finished machine or spare parts purchased separately.

Components and spare parts

In a simple machine for winding coils, an electronic counter of the number of turns is hardly required. The most common option for home use is a base with two wooden posts, two tubes with an axle. The rev counter can be an odometer taken from the bike. For a factory-made device, spare parts will only be required after a breakdown, so the choice of a device must be made deliberately. You can't just focus on cost or features that aren't always needed.

The comment was sent successfully.