The subtleties of filing a ceiling on wooden beams

The foundations for interfloor floors and roofs in our country are made mainly of reinforced concrete or wood. For the construction of the roof, interfloor and attic floors, logs and rafters from edged boards 150 by 50 mm are used. The material for them is a cheap type of wood (pine and spruce). Mauerlat is placed on brick and aerated concrete walls along the perimeter of the building, which serves to fasten rafters and logs. They are fastened to each other using grooves made in the lock and fix their iron tightening brackets.

The modern type of fixation consists of reinforced iron corners and plates screwed with self-tapping screws or nailed. Mauerlat can be made from the same edged board or from a bar, most often 150x150 mm or 150x200 mm in size. Lags can have the same size.

Logs often look like round timber, especially in rural areas. For outbuildings in the country or in the village, in order to save and afford the material, the rafters can also be made from not very thick round timber. It is difficult to achieve the ideal quality of evenness in such a structure, but you can significantly save financially.

The wood material should be used after proper storage, so that there are no distortions and the board is not twisted by the screw. Round timber must be cleaned of bark.

Peculiarities

For a new building, if it is not spontaneous, everything goes according to plan and according to the drawings. Questions arise when renovating or redeveloping an existing premises. Especially if it was built without your participation.

Building a new one is always easier than repairing an old one. But this is not always profitable from an economic point of view, and also requires a lot of time.

Difficulties can arise if the premises are used as permanently inhabited ones. For repairs, it is necessary to free up the space where the work will take place as much as possible. What could not be tolerated is carefully covered with plastic wrap or sheets... Dismantling is in progress.

In a one-story house of an old building, there will most likely be a dry screed made of expanded clay or straw with clay above the ceiling. There will be a lot of dust.

In a two-story house, it is not necessary to completely dismantle the floor covering for the first floor if there is a good floor on the top floor. It will be just more difficult to mount mineral wool heat and sound insulation. It is inserted in stages as the ceiling is sewn up; special plastic dowels with wide caps or tightening are used for fasteners. The length of the dowels is cut slightly less than the thickness of the insulating material and screwed to the floor of the upper floor with self-tapping screws, approximately 1 cm longer than the length of the dowel.

Foam insulation is installed much easier in this situation.

Materials (edit)

Any type of material is suitable for this type of work. You can combine several types at the same time. The ceiling can be made completely or partially flat. On such a surface, wallpaper or ceiling foam tiles are glued. And as an option, paint with oil or water-based paint.

Also use:

- Fiberboard... These sheets are cut so that their ends pass in the middle of the beam. For fastening the transverse ends, wooden blocks of 20x40 mm are mounted between the beams. You can fix them flush with the lags by cutting out recesses in them or into a spacer using an additional bar or metal corner. When working, you need to ensure that the fiberboard sheet does not sag. Nail it down. The sheets are mounted in a checkerboard pattern or simply with a seam offset.

- Plywood... If you do not mind losing the texture of the tree, then plywood sheets are nailed or attracted with self-tapping screws in the same way as fiberboard. The only difference is in the thickness of the cross bar, since plywood is heavier. The thickness also depends on the distance between the beams. When installing with self-tapping screws, a 2.5 mm pre-drill and a flaring hole are used to sink the screw head. Seams are putty with mastic or wood putty. For paint, the entire surface is primed and putty. The primer is used universal, putty without sanding.

- OSB boards (OSB)... An inexpensive material with the same strength, fixing and processing as plywood. Possesses good moisture resistance. The disadvantage is the presence of a substance such as formaldehyde in the resins that adhere wood chips. But if the material is made with high quality, then the formaldehyde emission is small. There are grooved slabs with a groove-rib on the edge, due to which they are assembled like a lining. There is practically no seam in high-quality slabs.

- Drywall... The most common material for these purposes. It can be easily mounted on both wood and aluminum frames. Thanks to this, you can make a multi-level ceiling from it. If a small insert is needed, it can be easily attached directly to the sub-ceiling. The peculiarity of its finishing is the sealing of the seams. To do this, use strips of a thin mesh. It is moisture resistant from 10 mm thick for unheated rooms or rooms with low humidity. But for outdoor work and rooms with high humidity, it is not suitable. For warm and dry rooms, there is a 9 mm thick plasterboard ceiling.

You can fill the ceiling with aerated concrete.

- Sandwich panels - good insulation. This option is used very rarely, because the panels are joined using an X-shaped plastic connector, and they are screwed to the lags with white-painted self-tapping screws with a press washer, which there is nothing to cover. But as small inserts, they are very suitable. They are glossy and matte. Do not require additional processing. Fastened to the rough ceiling with liquid nails using vertical spacers extending from floor to ceiling.

- The most popular material for a private house is wooden lining... It is natural and environmentally friendly. The ceiling sewn with it breathes, absorbing excess moisture in the room and giving it back in case of lack. In addition to its beautiful appearance, it is durable and plays the role of heat and sound insulation. A variety of wood textures, from which it is made, gives a wide choice for design solutions. It is made from coniferous and deciduous trees: oak, beech, ash, birch, linden, alder, pine, cedar. It differs in profile, variety and size. The width is from 30 mm to 150 mm. For the ceiling, a thickness of 12 mm is enough. The standard length can be up to 6000 mm, which makes it possible to cover the room with solid slats without splicing. There is a large selection of wood stains, with the help of which a color analogue of expensive ones is made from cheap wood species.

You can also play with the texture of wood with the help of varnish. For example, so that the lining does not turn yellow, it is first covered with a layer of nitro lacquer. It dries quickly without saturating the base and creates a film. On top, two layers of alkyd or water-borne varnish are applied.

With the help of varnishes, you can make the surface glossy or matte. The comb is attached to the groove, and to the logs with self-tapping screws or nails, using a doboinik, at an angle of 45 degrees into the groove of the lining.

- How the edged board is used for hemming... But this is more of a rough ceiling, because you cannot avoid gaps. An inch (25 mm thickness) is usually hemmed along the entire length of the ceiling. It can be fastened at 45 degrees to the side of the rail on a screed or through and through.

- Stretch ceiling looks beautiful (French)... Installation of such a coating is done after completed construction and finishing work.It is easy to make it with your own hands without the use of gas equipment and heating guns. Although the temperature in the working room will have to be raised in some way. From a special tool, you only need a spatula and a construction hair dryer. A household or professional hairdryer will work too. The color and texture of the canvas is chosen to taste.

When purchasing accessories for installation, you need to buy superglue. Using other glue can damage the canvas.

First, it is carried out and attached to the electrician's rough ceiling. Then the installation is carried out according to the instructions, which are purchased together with the accessories.

- Plastic panels are easily mounted on the ceiling... They look like a lining with a width of 50-100 mm. When assembled, they have a kind of seam between themselves, therefore they are called rack and pinion. A lining with very thin walls is suitable for the ceiling. It can even be crushed by hand and is afraid of mechanical stress, but it is lightweight and does not require a reinforced frame for fastening. It is usually white in color. Such material can be attached to wooden beams even with a construction stapler. A denser plastic without seam panels. Their standard width is 250 mm, they are wider than 350 mm and 450 mm. They are available in a wide range of colors, from glossy white and matte to imitation of different types of wood.

Well suited for bathrooms, but not for a bath. They can be applied not only for residential premises. They hem the ceiling on the veranda, gazebo, terrace, garage. The logs and beams that extend beyond the wall like a canopy are ennobled.

They are fastened to a tree with small nails with a wide head, and to a metal profile with self-tapping screws. They are easy to clean. Quality panels will not fade in the sun.

Siding and profiled sheet can be used to sheathe street structures: gazebos, garage, terrace, fence. Suspended ceilings, such as French, Armstrong, aluminum slats have nothing to do with beams. But they can be useful for a design solution - the device of such ceilings can be combined with other materials.

Structural diagrams

We looked at materials that are attached to the beams and completely cover them. The beams can be left open to increase space and create a special design. They can be hand-carved and varnished.

If they are solid, then you can leave them without additional machining. When they are prefabricated or look ugly, they are sewn up with another material. Old beams are cleaned of mold and mildew, treated with fire retardant and bioprotective impregnation.

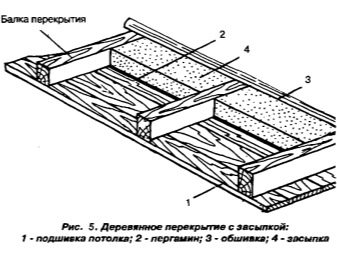

The scheme of the interfloor and roof overlap is the same:

- ceiling... There are rough and finishing;

- steam and waterproofing... Non-woven films, films with foil with a polymer reinforcing frame are used. It prevents the appearance of fungus and mold, prevents the absorption of moisture by the insulation, improves thermal insulation;

- insulation... Polymeric material is used: polystyrene foam, polyurethane foam, polystyrene foam. Organic: peat, straw, sawdust. Inorganic: expanded clay, perlite, vermiculite, mineral wool. It allows you to keep warm and serves as sound insulation;

- waterproofing... They use polypropylene films, roofing felt, glassine, polyethylene. It prevents moisture from penetrating into the insulation and onto wooden structures;

- floor or roof... For the floor, use a floor or edged board, chipboard, OSB, lining, plywood. For roofing: slate, metal, corrugated board, shingles.

Design features - use of a rough ceiling or without it. It is required if organic material is used as insulation. It is also needed when sheathing the ceiling with fiberboard sheets. If it is crooked, it should be aligned.

How to hem?

As a ceiling, you can use the floor covering of the upper floor. The selected material is pre-treated with an antiseptic and placed on top of the floor beams. Thus, the ceiling becomes higher and the beams become part of the interior.

A crate is mounted on the ceiling (floor) under the finishing floor of the upper floor. Then everything goes according to technology: vapor barrier, insulation, waterproofing, floor.

To leave the beams outside and save space in the upper room, a quarter is made in their upper part, the depth of which will consist of the thickness of the ceiling material plus the thickness of the insulation. A quarter can be made in advance with a circular saw before installing the beams or using a chainsaw in place. The ceiling material is cut into a spacer and placed a quarter between the beams. Further work is carried out on technology.

If you don't feel like messing with a quarter, you can knock a block in the form of a baguette (ceiling plinth) on the beams, and put the ceiling material on it... The lining can be fixed into a bar from the end at 45 degrees, and OSB, plywood and drywall - through and through.

When you need to insulate the lower room for interior decoration, and there is still no material for the ceiling lining, you can insulate it with mineral wool. To do this, tap a dense polypropylene film to the beams using a construction stapler. They overlap with an overlap of 25-50 cm, wrapping the edges on the wall, and the seams pass with metallized tape. At the bottom, a counter-lattice is made for the future ceiling. Mineral wool is cut and placed between the beams on the film. The top is covered with waterproofing.

Ceiling lining design solutions can be expressed in a combination of different types of materials, which can be given unusual shapes using electric lighting in different levels and directions.

The ceiling with elements of mirror coatings looks very nice. This solution allows you to increase the illumination of the room, highlight some part of the interior: a chandelier, bed, desk, corner, walkway.

Materials with a reflective surface:

- Ordinary glass-based mirror... Installation of such elements is expensive, the material is fragile and has a certain weight. But mirrors reflect light better than other materials. Glued onto liquid nails.

- Stretch mirror sheet... The maximum width of the film is 1.3 m, it is difficult to install, because it does not stretch. Excellent reflectivity. Perfect for small areas on the ceiling. There are also stretch glossy PVC films coated with varnish. They only reflect the surface without pure specularity.

- Plexiglass... It is made using the technology of ordinary glass, instead of which transparent acrylic plastic is used. There are also plastic sheets with a glued mirror film. They are lightweight and durable. Fastened like a suspended ceiling.

- Aluminum slatted and cassette ceilings... Unfortunately, the slats are easily scratched.

Useful Tips

If there is no special antiseptic, the tree can be impregnated with mining. This is engine oil that has reached its end of life. Such impregnation protects the wood, saves oil paint when using it.

Polyethylene film for vapor barrier of the ceiling at the roof is ineffectivebecause it creates a complete tightness. Because of this, a greenhouse process occurs, contributing to the accumulation of liquid, which, due to the temperature difference, destroys the properties of the insulation and provokes damage to the tree. Foil-coated polypropylene film must have a space of 1-2 cm between the insulation for ventilation. It is fastened with foil outward.

To avoid mistakes during installation, it is better to use Izospan material.... It is inexpensive and can be closely adhered to the insulation. The only fear is do not purchase Izospan hydro-insulating... It is necessary to pay more attention to the tightness of the joints of the film strips. To do this, use a wide adhesive tape, and it is advisable to choose the joints on the logs.

How to hem the ceiling on wooden beams, see the next video.

The comment was sent successfully.