How to properly putty a plasterboard ceiling?

Drywall is a versatile material for leveling various surfaces. Today it is very often used for arranging ceilings. A mandatory process after installation is leveling the base using special mortars. This is necessary if they plan to paint the ceiling or glue wallpaper on it. To exclude the appearance of cracks, it is important to follow a certain sequence of operations, as well as to use high-quality solutions.

We select the putty

Gypsum board consists of extruded gypsum, which is held in place by a special paper frame. Therefore, plasterboard ceilings should be putty only with compounds that can adhere well to such substances. Today there are several types of fillers.

Depending on the composition, the following types of products can be distinguished:

- Plaster mixes. Solutions are durable and environmentally friendly. But gypsum absorbs moisture very well, so they are not suitable for ceilings in the bathroom or in the kitchen. It is advisable to use them in dry rooms with minimal temperature extremes.

- Cement fillers. A great alternative for plasterboard ceilings. After drying, the plaster layer calmly withstands high humidity without cracking. Therefore, they can be applied in the bathroom, where there are special microclimatic conditions.

- Polymer compositions. Materials are obtained from various components with the addition of polymers. These substances radically change the physical characteristics. Experts recommend using them to form finishing screeds, as they lie evenly and form an even layer. With the help of polymer putties, it is easy to organize the ceiling for painting.

Another gradation of drywall mixes is the readiness level.

The most popular are dry solutions, which must be additionally mixed with water. Ready-made putties are presented on the market today, which, after purchase, can be immediately applied to gypsum surfaces.

When purchasing such mixtures, it is important to pay attention to their intended purpose. Today, solutions are used for start and finish alignment. Starting putties are characterized by a coarse-grained structure of granules, which does not allow obtaining a perfectly flat base.

Instruments

You can finish the suspended ceiling with your own hands without having a certain experience.

To simplify this task, you should stock up on a set of auxiliary tools:

- Mixing bowl and construction mixer. The power tool will be needed if the volume of work is large and you need to quickly prepare a high-quality solution. When the room is small, mixing can also be done by hand.

- Wide paint brush and spatulas. The size of the last tool is selected individually. You need to have several types of spatulas, as they will be needed in certain areas of the ceiling.

- Abrasive mesh and floats in several sizes. Used to level surfaces after the solution has solidified.

- Painting grid. The main purpose of the product is to mask and fix seams.

Surface preparation

Before starting work with the ceiling, it is advisable to free the room as much as possible from furniture and unnecessary things. During the filling process, there can be a lot of dirt, which will then be difficult to wash off.

Ceiling preparation begins by adjusting the screws.Fasteners must be screwed in so that their heads do not protrude above the surface of the drywall. You can check this by touch. If such shortcomings are present, then using a manual screwdriver, the self-tapping screws are screwed into the depth of the material.

Do not form too deep a fossa, as this can lead to pushing of the frame or its curvature. It is necessary that the head only slightly deepened relative to the upper plane.

Sometimes during installation it happens that the self-tapping screw strongly presses the sheet, and a small depression forms in this place. This defect can be corrected by twisting the fasteners to a new place, but only with less effort. When everything is ready, all the pits at the locations of the screws are sealed with mortar. It is applied into the grooves with a spatula, performing crosswise movements.

The next step is to align the seams between the sheets.

This process is simple and involves several sequential operations:

- Initially, all dust is removed from the ceiling surface with a regular brush. If during the arrangement drywall was used without a factory edge, the joints are cut at an angle of 45 degrees. When bevels are still present, you should check if the paper is peeling at the ends. If such a phenomenon is present, it must be carefully cut off with a clerical knife.

- After that, using a painting knife, several thin cuts should be formed along the seam. They are needed for better adhesion of the solution to the gypsum.

- At this stage, the entire ceiling is primed with special solutions. Do not use alkyd compounds for this, as they damage the structure of the paper and it loses its original strength. It is worth using only high-quality specialized fluids intended for gypsum.

- The preparation is completed by grinding the hardened mortar at the locations of the fasteners. This step is important, as the number of putty layers applied and the surface quality depend on it.

Sealing of seams

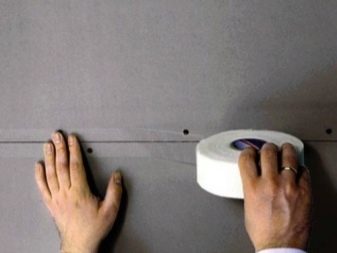

Ceiling putty begins with this step. To obtain a strong system, all joints between the sheets should be additionally reinforced with a serpyanka mesh. You can buy it in specialized stores, you just need to choose the desired cell size.

The technology for filling seams is quite simple and consists of the following steps:

- Filling the joints with a small amount of mortar. It is important that the mixture does not completely fill the pits as it will be difficult to attach the reinforcement tape.

- Fastening the serpyanka. Place it along the seam so that it is strictly in the center. To fix the mesh, the material is slightly pressed into the solution. It is important not to bend the mesh too much so as not to get an arc.

- Alignment. After fixing the serpentine, another layer of plaster should be applied to close it. This allows a relatively flat surface to be achieved. All work is carried out with a wide spatula, which covers the width of the seam and the applied mesh at a time.

When applying the putty, it is advisable to let each layer dry a little. This way you can evenly distribute the next portion of the mixture.

Strengthening the corners

Plasterboard ceilings have more than just one plane. Today, multi-level boxes have gained particular popularity, which form a decorative surface. These structures are distinguished by the presence of internal and external corners, which it is desirable to strengthen. Depending on the type of angle, these operations are performed differently.

Internal

For such systems, perforated corners are used, along the edges of which a serpyanka mesh is attached. It allows you to tie sheets together, while obtaining a rectangular joint.

The inner corner is fixed to the surface with a small amount of solution. Then, using the same mixture, the serpyanka is also attached, leveling it along the base of the sheet. After that, using an angled spatula, putty is applied and the angle is leveled relative to the level.

External

Corners of this type are somewhat easier to attach. Initially, a small amount of solution is applied to the end of the sheet. After that, an aluminum and plastic structure is pressed into it. When it is leveled, the rest of the mixture is removed with a spatula.

To achieve a perfectly even angle, putty should be applied in several layers. Moreover, each of them must dry out so that the quality of the coating can be controlled at the next stage.

Finishing putty

This stage is final, as it allows you to get an already beautiful and even surface.

Finishing involves performing the following sequential operations:

- Using a wide trowel, spread the mixture evenly over the ceiling. It is important that the thickness of the mortar does not exceed 2-3 mm. Otherwise, it can lead to cracks or putty falling off.

- Clean the spatula before applying the solution to the new area. The surface is also formed by stretching the material in a thin layer.

- If you have not achieved the optimal effect, you can try applying another layer of putty over the starting material. Such restoration operations are carried out over time, when the ceiling turns yellow from adverse factors.

The leveling quality depends largely on the angle at which the trowel moves. The optimal indicator is a value of 15 degrees.

This will allow you to achieve an even coating without forming a web of several layers. It is advisable to carry out all work on leveling the ceiling in a room where the temperature varies in the range from +5 to +30 degrees.

The putty should dry only in a relatively damp room without exposure to direct sunlight. Too fast evaporation of water will lead to the formation of small cracks, which can only be removed with a new putty. When the screed is dry, it should be sanded. This is done with a float and fine sandpaper.

Plastering a plasterboard ceiling is a laborious and time-consuming procedure that requires compliance with all the rules and the choice of only high-quality building mixtures.

For more information on how to properly putty a drywall ceiling, see the next video.

Putty "Polyfill". I was very afraid that it would not fit on a drywall ceiling. But no, in the end everything is perfectly smooth, the result is great.

The comment was sent successfully.