Features and purpose of the scherhebel

Wood is an easily processed material that is used in many industries in the manufacture of various products. In the course of its processing, a fairly wide range of tools is used. At the moment, many are interested in the purpose and features of operation scherhebel. This tool has been an integral part of the arsenal of both production lines and home workshops for many years.

What it is

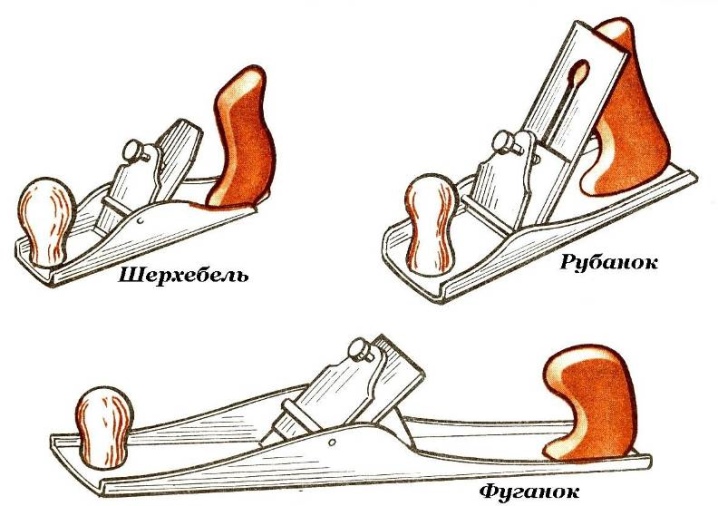

It is very difficult to imagine performing even the simplest joinery work related to woodworking without the use of specialized tools. Among other things, the corresponding sets of devices include various modifications of planers, sherhebel, as well as jointing planes. Despite the certain similarities, it is worth figuring out what each of them consists of and what they are intended for.

In particular, the scherhebel is a kind of heavy artillery in the arsenal of carpenters. It is needed for rough (primary) wood processing.

It is important to take into account that as a result of such planing, it is only possible to give a certain shape and size. By definition, it will not be possible to achieve a flat plane with such processing.

You can see the Sherhebel in action in the next video.

Scherhebel allows for extremely rough processing. Unlike its counterparts, it provides maximum depth planing. This tool easily handles even significant irregularities. By the way, outwardly, the scherhebel is very similar to an ordinary plane, and an inexperienced person can easily confuse them, not knowing the features of each of the tools.

One of the most important points is design, location and sharpening of a scherhebel piece of iron. It has a rounded blade that is positioned at a 45 degree angle to the sole. Depending on the operating conditions and, in particular, the hardness of the treated wood, the knife sharpening angle. So, when working with soft rocks, this indicator ranges from +25 to +30 degrees, and in situations with denser material - +35 degrees.

Classic design the described type of tool provides for the installation of a knife with a blade width of 35 mm. This parameter may vary for different modifications. but block will always be about 15 mm wider than the knife.

If we compare the scherhebel with a plane, then it is necessary to pay attention to the fact that the first hole for the removed chips is larger by a few millimeters. This is due to the depth of planing, and, consequently, the thickness of the removed layer of wood. And it is important to remember that after using this tool, traces in the form of grooves remain on the surface.

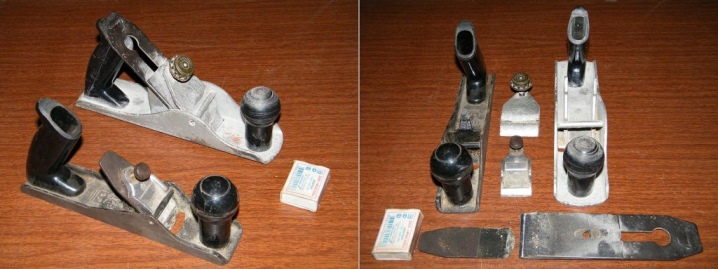

In the arsenals of modern masters there are sherhebelles with pads, made of both wood and metal. Considering this point, the design of the models may differ. It should be noted that wooden images are produced in accordance with the requirements of the current GOST.

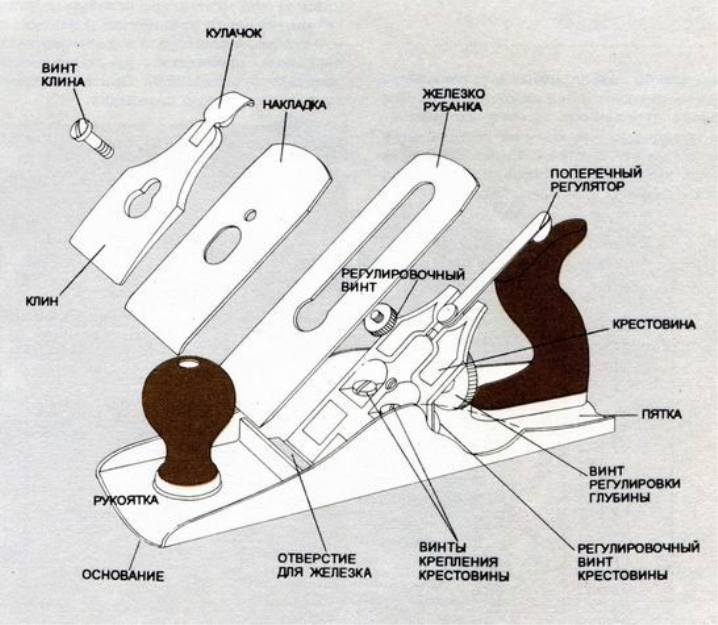

In accordance with current regulations, such designs include the following:

- rectangular body;

- handles for conveniently holding the device during its operation, also referred to as "horns";

- cutting element;

- fixing wedge;

- the so-called scherhebel sole.

In addition to all of the above, some sherhebel have stop for the cutting element. It is also important to consider that all wooden parts are covered with high quality varnish. This provides quite effective protection against damage and wear resistance, and also significantly extends the service life of the tool.

The GOST standards provide for the following materials for the manufacture of individual parts of the scherhebel:

- sole - acacia, hornbeam, beech, ash or maple;

- block - solid wood;

- pad pad - the types of wood listed above, as well as the list of species includes birch and elm;

- the blade of the knife is made of two-layer steel - the raw materials for the main layer are grades 30, U8, U8A or U9, and in the manufacture of the cladding, grades 9ХС, 9ХФ, 9Х5ВФ, and also Х6ВФ are used; in addition, the current standards allow the use of steel of other grades, provided that the resistance indicators are consistent.

Metal models have a die-cast body with a rigidly attached hilt (horn)... The knife in such sherkhebel is fixed with a special screw assembly, located between the clamping element and the base. Compared to their wooden counterparts, metal devices are characterized by maximum durability.

However, many experienced craftsmen prefer wooden sherhebel. This is largely due to the level of quality of wood processing.

What instrument does it look like

Today, manufacturers of joinery tools present on the market more than a wide range of their products. At the same time, novice craftsmen often have questions related to how the scherhebel looks like and how it differs from similar instruments.

First of all, this applies to planers, since it is to him that the scherhebel looks most like.

Another representative of this family is jointer. By and large, we are talking about a hand planer, the main design feature of which is the presence of a double knife. It is important to remember that this tool is used exclusively for finishing. The elongated block allows you to level the surfaces of a fairly large area with the highest quality.

This structural element is several times superior to the similar parameters of the Scherhebel. Among other things, the jointer knife has a so-called chip remover.

What is the difference between a plane knife and a scherhebel knife

Taking into account the external similarity and identity of a number of structural elements, Sherhebel can be described as a plane that is used exclusively for roughing.

The key difference between these two varieties is features of the incisors. First of all, it must be recalled that the described type of carpentry tool has knives with a semicircular blade. And also knives differ in their width. This means that wider elements are installed on the plane. It is equally important that the Sherhebel the knife protrudes 2–3 mm in relation to the block... The rounded shape and reduced width provide increased productivity and the deepest possible infeed.

How the blade is installed

Initially, it is necessary to focus on the fact that carpentry knives are usually operated at maximum loads. In this case, we are talking about the maximum shear stress. One of the key points in this will be features of the processed material.

If this parameter is not taken into account, then the stability of the scherhebel knife during operation is directly determined by the dimensions of the passage. This refers to the maximum length of the breaking off parts of the removed chips. With a decrease in this span and a parallel decrease in the planing depth, the surface of the workpiece to be processed is gradually leveled.At the same time, there is a significant weakening of the shear load on the metal from which the blade is made.

To understand how to properly adjust the scherhebel knife, you should pay attention to some important points. First of all, we are talking about design features of this item. It includes support and working parts. In the configuration of the latter, the following are distinguished:

- a chamfer formed on the rear side and provides a decrease in the force of cutting the blade into the wood being processed; this is due to the fact that friction of this very rear plane against the surface to be treated is eliminated;

- rake angle - a parameter, as a rule, identical to the inclination of the cutting element to the Scherhebel body;

- back angle;

- working angle - in this case we are talking about the difference between the angles of inclination and chamfer.

It should be noted that the tool life is largely determined by the rake angle. Not only the quality of the surface of the workpiece, but also the process of removing the removed chips and the load on the knife itself directly depend on it.

Choosing the optimal value of this angle, you need to pay special attention to several points:

- Physical characteristics and individual characteristics of the processed wood. In particular, the point is that the angle increases with increasing material hardness. When working with larch, pine, aspen or linden, it is recommended to position the blade at an angle of 45 degrees (± 5). When processing harder species (oak, hornbeam, pear and others), this parameter is 60 degrees (± 5). If the density of the material is even greater, then the angle is increased to 80 degrees.

- Planing type. As a rule, for each type of wood, there is an optimal angle of inclination of the blade and the tool itself in relation to the plane of the workpiece. So, for pine it will be 40–45 degrees. The change in this indicator determines the quality of planing. However, it is important to take into account that in this case the metal will heat up more intensively, therefore, it will become blunt much faster.

- The material from which the knife itself is made and its main characteristics... First of all, attention is focused on the hardness of the steel. Most often, in the production of blades, high-speed grades P12 and P18 are used. By the way, some craftsmen, when making knives on their own, quite successfully use elements of friction saw discs as blanks.

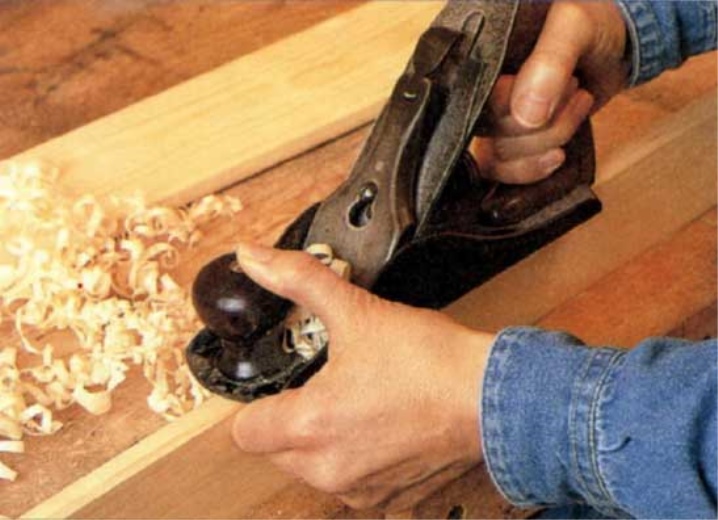

At the preparatory stage, before each use of the tool, its adjustment is carried out taking into account the existing norms and rules. To do this, you need to do the following:

- place the tool so that its sole points up;

- visually determine how much the edge of the blade protrudes - in a situation with a scherhebel, this value should be 3 millimeters; a ruler can be used to measure the height of the knife;

- make sure that there are no even minor distortions; the blade should be positioned strictly parallel to the sole.

To properly fix the knife in the tool body, it will need to be disassembled. In situations with wood models that have a fixing wedge, the algorithm of actions includes the following points:

- the plow is placed in the left hand, holding it by the block;

- with the other hand, with a hammer or mallet, light blows are applied to the back of the tool until the wedge is completely released;

- the blade is exposed in the appropriate position and wedges;

- with a hammer, the wedge is driven to the end; as a result of such manipulations, the part is held motionless;

- the correct installation of the cutting element is checked.

Important! When adjusting the scherhebel, remember that the knife will move slightly during the jamming process. Based on this, it is exhibited with a small margin. They get rid of distortions with hammer blows on the sides of the blade.

In situations with metal models, the entire procedure described is as simple as possible. As noted above, the blade of such sherhebel is fixed using a screw mechanism. By the way, this node also performs the functions chipbreaker or chipbreaker. This knot prevents chipping of the layers of wood removed during the planing process.

How to sharpen

Unfortunately, even the highest quality tool steel used in making scherhebel cutting elements cannot provide sufficient wear resistance. With active use of the tool, the blade "sits down" rather quickly, which negatively affects the quality of processing. Based on this, it follows timely sharpen and straighten the cutting edge, paying particular attention to the sharpening angle.

This procedure has the following important features:

- the cutting element must be positioned at the correct angle;

- sharpen the cutting part exclusively with the help of special stones; it is important to remember that the lower part of the cutting edge is drawn along the surface of the sharpening bar;

- it is constantly required to ensure that the sharpening angle is the same;

- when processing metal, burrs most often appear, they must be eliminated, since such knives cannot be used; getting rid of such defects is quite easy - you will need to process the reverse side with several movements;

- at the final stage, the blade is straightened using a richly moistened grinding stone (whetstone); experienced specialists recommend doing this in a circular motion, which avoids the formation of defects.

It is important to remember that when sharpening, distortions must not be allowed. Such flaws will inevitably lead to a decrease in the quality of planing, as well as a blockage of the space between the blade and the block.

It is necessary to get rid of even seemingly insignificant distortions, which will significantly extend the service life of the cutting element.

A clear and detailed overview of the device and the purpose of the Scherhebel is presented in the following video.

The comment was sent successfully.