Cutter for metal profile for drywall

A cutter, or a broach, is today called a tool whose function is to fasten metal profiles and profiles from other materials for drywall or other facing material. Any person who dares to make repairs on their own knows that to install drywall, steel structures from a metal profile are first mounted.

There are several opinions regarding the means of its fastening. Most craftsmen tend to use self-tapping screws or screws in this capacity. To perform such operations, you will need a screwdriver or an electric drill with different nozzles, as well as a decent number of self-tapping screws themselves.

An alternative to this method is metal profile punching using special devices / tools. They are called that - cutters for metal profiles for drywall.

What it is?

Today drywall is used in almost any renovation. It is used when building partitions, finishing work rooms, classrooms or living rooms. The production of curly multi-level ceilings, the execution of cladding and the installation of plasterboard walls is only a small part of its scope. Facilitates and speeds up the work of such a common and convenient tool as a metal profile cutter for drywall.

To install a plasterboard partition or wall, you will need a variety of tools: a hand / electric screwdriver, different types of screwdrivers, and a variety of hardware. The profile cutter is very helpful in fastening drywall sheets and metal strips. When using it, you can do without self-tapping screws or other fasteners.

There are three main modifications of the firmware:

- A hand model that makes fasteners by hand.

- The reinforced model is a professional modification of the divider with the possibility of replacing the working parts. It is designed to work with a profile of complex shape, if physical effort is required.

- Professional model using multi-stage punches.

The latter modification has a higher cost and has greater weight and dimensions. The scope of its use is objects requiring a large amount of repair work. To operate it, you need to have certain knowledge and practical skills.

How to work with the tool?

Since it is quite easy to use the cutter, instructions for its use will be extremely simple:

- the parts to be connected are combined by overlapping;

- the area of their connection is brought into the working area of the cutter;

- the handles are brought together to a click.

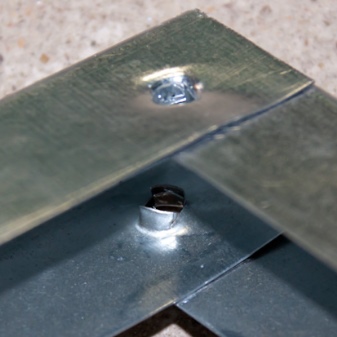

The resulting sample is connected to the surfaces of the parts. Countersinks (a type of punch shape), as a result of bringing the handles together, make a hole with a certain type of edges. Edges fold and bond for improved fastening. The general punching layer has limitations in thickness (0.55-1.5 mm) and a diameter that depends on the diameter of the punch - from 2 to 5 mm. Notches can be used for chamfering.

Features and Benefits

Installation of plasterboard cladding sheets involves two main options for their fastening:

- fastening with glue;

- fastening to a metal frame.

The latter method, of course, to some extent "eats" the useful free area of the room, but the masters prefer to use it.The choice of this option is optimal in order to firmly fix the guides to each other. This connection has the highest strength and reliability compared to other methods.

Many people express very different opinions about the use of a cutter. Someone considers it to be a basic necessity for repairs, while someone thinks that attaching something to drywall in this way is the height of unreliability.

The main thing for which the divider is valued is the absence of hardware for fasteners, that is:

- he makes the connection without the use of self-tapping screws / screws, and therefore, there is a big saving in material and time;

- since the use of self-tapping screws / screws is not expected, the use of a cutter also significantly saves finances;

- unnecessary holes in drywall and profile are excluded;

- the material itself does not deform, there are no burrs, dents, any roughness;

- if there is no need to purchase replaceable working bodies (stamp, punch) for the cutter, this is also an economy, since you do not need to spend money on their purchase;

- the absence of a protrusion of the screw head makes the adhesion of the drywall sheathing sheet to the profile closer;

- no electrical connection required to connect electrical tools;

- a small cutter is used with one hand;

- the shape of the cutter body varies widely and largely depends on the developments of a particular manufacturing company;

- during operations with him, only physical strength is needed to press the handles;

- a high-quality cutter connects surfaces securely.

One cannot but say about the opinion of the supporters of the opposite camp - those who do not accept this type of connections. Above we talked about the quality of the cutter, so some of the concerns are still justified, since a low-quality flasher will not be able to provide a reliable connection.

Varieties

Conventionally, in terms of functionality, the cutters are divided into the following varieties:

- small types cutters are more popular because they are cheaper in cost and more convenient to use when it comes to repairs that are carried out from time to time;

- enhanced version the stitcher is convenient for the work of small repair teams, if they mean work in household and utility rooms;

- professional cutter should be used in the implementation of large-scale projects, with large volumes of capital construction, when installing partitions in the premises.

The first two types of such instruments are attractive because of their low cost and relatively small size. The third type of cutter also has its advantages - it can be operated for a long time, it can perform more functions. There are also cassette cutters, flexible, using a needle roller.

It is necessary to make a small remark: some dividers are used to work with the profile of the same manufacturer, respectively, they cannot be called universal. Therefore, before purchasing it, it is necessary to determine the types of profile that are going to be used, as well as the manufacturer of tools and consumables.

Tips & Tricks

You need to know the following:

- to create a hole or high-quality fastening, you need to use only the tool that is designed for the corresponding thickness of the metal profile;

- when punching, it is forbidden to make sharp displacements of the parts and the cutter itself, since this will lead to insufficient quality of the cut section;

- it is prohibited to hit the instrument to enhance the breakdown;

- install the cutter only in position 900 to the material to be joined;

- in the areas of joining of metal profiles or where the profile was increased, it is prohibited to punch a groove;

- the joint joint of the cutter parts must be regularly lubricated with an appropriate type of lubricant.

It is necessary to use a plasterboard metal profile stitching tool that matches only those parameters and metal thickness that are intended for it. In case of deviation from the operating rules, the service life of the cutter is reduced or this leads to its failure.

Manufacturers

Construction trade networks offer products from different manufacturers of cutters / stitchers. Of course, each of the brands offers its own version of the tool, which has certain advantages and disadvantages.

Knauf

This construction tool mounts galvanized plasterboard slats comfortably. With the help of pliers, the marking of the gypsum board is facilitated and the fasteners are controlled. Pliers make it possible to hold a sheet of drywall in a vertical position when installing the walls, transfer sheets in this position and mark flat surfaces. Knauf cutter is structurally simple and effective.

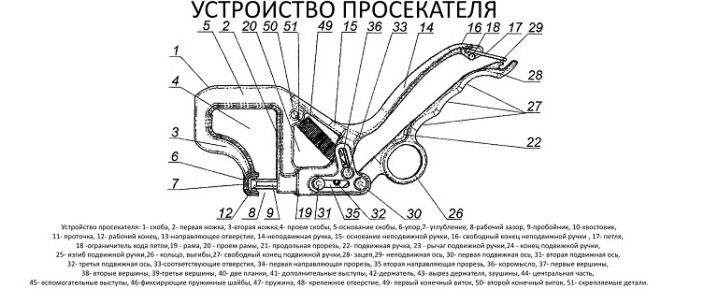

Knauf's Shtantsange cutter is one of the least intricate examples of such a tool and has only three structural elements:

- bracket equipped with "jaws" and a fixed handle;

- the second unlocked handle has a mounted transmission device;

- working tool (striker).

This is a very simple device, it can be used as a plumb line when attaching the profile to the ceiling surface. "Shtantsange" is strong enough to hang on it an electric drill or other equipment that is necessary for work.

Knipex

Fastener manufacturers in Germany have excellent references from construction market participants and buyers. The purpose of these pliers is to fix metal profiles by a cut with bending of small pieces of metal. They can be easily used by home craftsmen for non-capital repairs, if the use of self-tapping screws and other fasteners is not provided, which will make the level of work much more productive.

It is allowed to perform work using only one hand. Such a stitcher is designed to work with a metal profile for drywall and metal sheet up to 1.2 mm thick.

Matrix

The device of this brand greatly facilitates all types of work for both a beginner and a professional. It fixes the rails of the posts or rails on the ceiling when carrying out repairs. A useful constructive addition - it can be used for undercutting, bending and forming corners of a galvanized profile during its installation.

By purchasing a plasterboard profile stitcher from this manufacturer, you can forget about self-tapping screws / screws, incorrect installation and making a large number of unnecessary holes that reduce the strength of the structure. The Matrix brand tool is renowned for being effective, durable, resistant to aggressive environments, durable and reliable.

Specifications:

- punching layer - 0.6 mm;

- dimensions - 250 mm;

- weight - 1.75 kg;

- the stamp is made of U-8 brand tool steel;

- handle material - rubber;

- one-handed use;

- made in China.

The characteristics of the punched hole: cleanliness, no burrs, two bending tabs on both sides, no dents on the surfaces.

Stanley

Stanley has earned a reputation as a worthy and reliable manufacturer of various types of tools. The reinforced punch can also be attributed to the same definitions. Fields of application: during installation work, construction, repair and redevelopment of household and industrial warehouses, rooms. Also suitable for bonding U-shaped frames for gypsum plasterboards.

The stitcher has a powerful transmission mechanism, equipped with movable ergonomic levers with rubberized surfaces that allow one-handed operation, and this is an important nuance when repair work is carried out without the involvement of outside labor.A functionally important addition is a locking clip-retainer, similar to those used in the models of hole punching machines. This will prevent sudden traumatic abnormal opening of its handles and prevent injury in the folded position when the tool is not being operated.

Specifications:

- pierced layer - 1.2 mm;

- dimensions - 240 mm;

- weight - 730 g;

- the working surface is made of oxidized steel;

- covered with protective black varnish;

- handle material - rubber;

- one-handed use;

- made in China, USA, Taiwan.

The splitter is impact-resistant, resistant to aggressive acids and alkalis, which significantly increases the time of its useful use.

"Zubr"

Acquaintance with a professional Russian-made riveter can be started with the fact that it is designed for quick fastening of galvanized strips with their thickness up to 1 mm. Scope of "Zubr" application - installation work during construction work and overhaul. The strength of the connection is ensured by punching 1.5 mm holes and then bending two petals. Screws / self-tapping screws are not used.

The cutter is equipped with replaceable stamps made of high-strength steel grade. The handles are covered with rubber. Protection against rust is provided by galvanized surface, which is important when working in high humidity conditions.

Specifications:

- punching layer - 1 mm;

- size - 250 mm;

- weight - 800 g;

- stamp - U-8 tool steel;

- handle material - rubber;

- one-handed use;

- produced in Russia, China.

The riveter has a good degree of wear resistance, is distinguished by a long service life, and increased reliability.

There are also a number of device manufacturers with positive reviews on the Russian market: Topex (the most popular models are +350, 43e100, 68 mm), Fit, Matrix, Hardy, Makita, Santool, Sparta. Almost all of them fall under the same price and technical characteristics, and also have approximately the same popularity among buyers.

In conclusion, we can say that metal profile cutters for drywall panels are modern tools for builders, repairmen and just home craftsmen. By resorting to their help, it is relatively easy to re-plan and insulate a wall, a lintel or a multi-level ceiling with plasterboard.

If you use a cutter, you can forget about inconvenient and small fasteners and accessories, broken screwdriver handles and hand injuries due to non-compliance with safety precautions.

In the next video, see an overview of cutters for a metal profile for drywall.

The comment was sent successfully.