Pliers: what is it and what are they?

The term "pliers" came to us from the French language, in translation it means "to clamp the rod." The design features of the pliers fully correspond to this description - there are round or oval grooves on the clamping edges, which are designed to grip and hold tubular parts in the shape of a cylinder well.

What it is?

Pliers are a very popular tool in the home craftsman's set; craftsmen - locksmiths, mechanics, as well as electricians and other specialists - cannot do without them. With all the richness of the choice of a variety of tools, the more necessary product, perhaps, does not exist. Pliers belong to the working equipment of the hinged-pliers type, they are indispensable for gripping thin pipes and parts of various shapes.

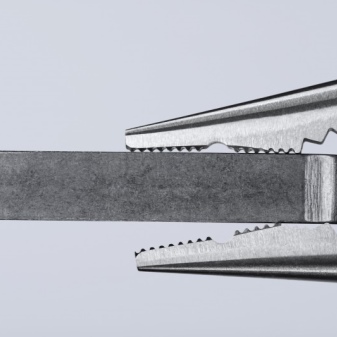

Pliers combine the structural elements of pliers and wire cutters. Special notches are applied to the sponges of such a device; the fixation strength of the captured part largely depends on their configuration and size. Notches can also be made on the back of the hinge, a little closer to the end of the handle, thanks to such features, the part can be held with either side of the pliers.

From the point of view of geometry, almost all modifications of the pliers are made in the same way, while the longer they are, the more tangible force needs to be created on the jaws.

When creating modern models, much attention is paid to sharpening cutting edges, usually they are sharpened at different angles, and hardening is performed according to special conditions that vary for each manufacturer. The assembly of the tool greatly affects its quality: in an ideal design, the hinges should not have any backlash and any gaps, while the tool handles should move apart effortlessly with the fingers of one hand.

Many inexperienced users confuse pliers and pliers. These are devices with a similar purpose, but nevertheless completely different.

- The main difference is that, in addition to the oval recess, the pliers also have a cutting edge, and at the point of the hinge joint, a notch is provided for cutting metal materials.

- Technically, pliers are a more powerful tool than pliers, they are made from chrome vanadium steel, which is characterized by increased strength and durability, the hardening degree reaches 53 HRC.

- In addition, pliers are usually larger than pliers, they have more massive clamping jaws, but at the same time are shorter.

- Multi-functionality is inherent in pliers, while pliers are used narrowly.

Types and characteristics

The modern market for household and professional tools offers a wide selection of pliers of a wide variety of types, sizes and designs. They are sliding, adjustable, adjustable, expandable, multifunctional (universal). Pliers can be used to install eyelets, remove retaining rings or strip wires, there are also models for clamps and products with a retainer, the length of the tool can be 160, 180 or 200 mm.

Models that allow you to adjust the compression force of the jaws and the parameters of the distance between them are very popular, thus significantly expanding the range of dimensions of the elements to be gripped.Many models are equipped with side cutters, thanks to which you can peel off the insulation from the cores, as well as cut thick wire; on tools for cutting durable metal, special knives-edges are provided on the front part.

Dielectric

Dielectric pliers are equipped with special handles with a reliable insulating coating, such devices are suitable for carrying out electrical work carried out under high voltage, and also allow you to effectively replace equipment and metering devices. Thanks to the soft, ergonomic handles, all necessary manipulations can be performed quickly and easily.

As a rule, the plastic here is reinforced with fiberglass, this contributes to an increase in strength.

The handles are ribbed, which prevents slipping of the palms at the time of work. The jaws are equipped with small teeth for a more physiological grip of the material. The weight and dimensions of the tool are relatively small, so the work does not cause fatigue for the operator.

Luvers

Grommet models are the most popular, they are mainly needed to solve everyday problems associated with the need to hang new curtains and curtains. Everyone knows that when sewing fabrics, metal or plastic rings are used, usually their diameter does not exceed 7 mm, they are called eyelets. Thanks to special pliers, the work is greatly simplified: you need to make a little physical effort and the rings will be securely fixed on the material.

Combined

These models are needed to perform various functions, they combine the elements of side cutters, pliers, nippers and other tools. Like most similar models, they are made of high-strength carbon steel, the edges of such tools are certainly hardened to increase their service life.

In combined tools, all metal parts are additionally polished and coated with special compounds.

If necessary, these tools can be strengthened by the use of devices that allow you to grip and hold even pipes, since they provide for the possibility of adjusting the parameters of the opening of the jaws.

Models

Modern models of pliers are characterized by reliability, ergonomics, functionality and at the same time require a minimum of effort during work. The most in demand are tools from such world-renowned manufacturers as Zubr, Wiha, Gross, as well as Knipex and Sparta.

Gross 16972

This is a convenient and practical model. The tool's pivot is offset towards the working end, which increases the cutting force by 20% compared to standard pliers. At the same time, the amount of effort applied remains unchanged. The handles are rubberized, which provides a comfortable grip and uniform distribution of the load.

All metal parts are protected from corrosion by Titan Finish, which significantly increases the period of use of the tool.

The cutting edges are made of steel, hardened by induction currents, due to this, they retain their sharpness for a long time. The inner part of the instrument is equipped with a loop, which greatly facilitates its storage.

Knipex KN-0202180

The model is distinguished by the exceptional hardness of the cutting edges, which makes it possible to bite through metal wire of various degrees of hardness and even piano strings without any problems. The design is balanced, the efforts during the work are distributed evenly, this makes the work comfortable and safe.

Compared to conventional pliers, the work requires 30-35% less effort.

The metal elements are made of forged and oil-hardened tool steel. The shape of the cutting edges is elongated, which makes it possible to bite even a copper cable with a diameter of 11.6 mm. The handles are made of polymer with anatomical rubberized gaskets.

Sparta 17826

Combination pliers that allow you to work in the most difficult-to-reach areas. The advantages of the model include the small size of the tool, due to which all manipulations can be carried out with maximum accuracy. Working elements are made of durable steel and coated with nickel-plated compounds, which prolongs the service life, protects against rust and mechanical wear.

A distinctive feature of the tool is the presence of an auto-clamping clip, this allows you to wield more efficiently in situations when the other hand is busy.

The handles are ergonomic, provide a perfect grip, which prevents the pliers from slipping during operation.

How to choose?

The efficiency of the work largely depends on the quality of the tool itself.

- To check the pliers, you just need to visually inspect the end of the compressed jaws: if you notice two rectangles of regular elongated shape, of the same size, most likely you have a product in front of you that meets all the necessary technical and operational requirements. Manufacturers usually do not pay attention to this detail, while the correct configuration of the jaws directly indicates the build quality.

- Special attention should be paid to the metal that was used to create the tool. When manufactured under factory conditions, the composition of the raw materials must be observed very strictly. In addition, a special heat treatment technique must be observed, this gives the working elements the required hardness and strength.

- Cutting edges and jaws of the highest quality models are additionally hardened with high-frequency currents. Such models cost much more, but the quality of their work is much higher.

- The type of tool coating can tell a lot about the quality of the model, since the resistance of metal parts to corrosion depends on it. Most often, surface treatment is used, in which the tool is placed in hot oily steam, after which it is coated with a special varnish.

This treatment is often referred to as oxidation; this protection is not particularly effective if the work is carried out in high humidity conditions.

That is why such tools are only suitable for interior work. If you intend to work in open air conditions, you need more durable protection, for example, chrome plating - such products are easily distinguished by their aesthetic steel sheen.

The highest quality zinc coating is considered, it is not only not inferior to the above, but in some points even surpasses it. In particular, it more effectively protects the instrument from mechanical damage and deformation, but the appearance of the product is no longer so aesthetic.

It is important to take care of the comfort of working with the tool, which is why special attention should be paid to the handles, which can be of several types.

- Standard - are made of plastic that does not emit toxic substances. Such tools are quite affordable.

- Ergonomic - made of plastic, additionally equipped with rubberized pads. This feature allows you to significantly increase the ease of use. However, it is important to make sure that the rubber is made from high quality raw materials, otherwise the person may develop allergies when in contact with the tool.

- Electrical insulating - are made of materials that protect the employee from electric shock during manipulations under voltage up to 1000 V.

It is also important to make sure that the linings are firmly attached. Most cheap Chinese-made models do not differ in quality: plastic handles often slide off and this significantly complicates their operation. In the most budgetary models, plastic handles are glued, but a hot fit is considered more reliable.Then the handles are put on while still hot, and as they cool down, their temperature shrinkage begins, due to which the handle is securely fixed on the base of the tool.

If you have the financial ability, give preference to professional models made in accordance with the requirements of GOST, since they are much more convenient to work with.

If you buy a branded model, and not a fake, then one purchase may be enough for you for the rest of your life.

Usage Tips

To make your instrument last as long as possible, it is necessary to adhere to some rules for working with pliers.

- The tool must always be lubricated.

- Gripping involves the application of effort to hold the product, for example, it is necessary in order to guide the part and not allow it to slip. The grip must be non-violent, otherwise the pliers can be damaged, which will disrupt the grip of all flat elements of the part.

- If you are working with live elements, then you can only hold the tool by the insulated handles.

For information on which pliers are better, as well as testing different models, see the video below.

The comment was sent successfully.