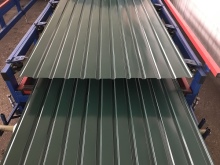

Features of professional sheets C10

The article describes the main features of C10 profiled sheets: dimensions and weight, working width and technical characteristics. Disassembled features of different types, including curly sheets and conventional panels for the fence, roof and walls. Recommendations for product selection and basic installation rules are given.

Applications

C10 professional sheet, like other brands of corrugated board with marking C, is in demand mainly for wall cladding. The insignificant height of the waves makes it possible to install it in a complex structure. Since the material is relatively resistant to mechanical stress and corrosion, it is reliable. The surface of the material does not have pronounced stiffeners.

Therefore, it is not possible to provide exceptional strength, as with a larger corrugation.

However, such products are quite acceptable as a wall structure. Profile C10 will be appropriate for the construction:

-

kiosks;

-

trade and exhibition pavilions;

-

hangars;

-

warehouse complexes;

-

fire barriers;

-

indoor and outdoor fences.

In the latter case, we are talking not only about the use for a fence in the country or in a private house. A fence around a construction site or boiler room will also work as a target. Thanks to a special polymer coating the profiled sheet looks visually attractive. It becomes pleasing to the eye even when decorating residential and office premises.

It is hardly reasonable to use C10 material for the roof, since it has too little rigidity.

If it is possible to use a profiled sheet of this brand for a roof, then only with a great steepness. Then intensively sliding precipitation will not create a powerful load and will not violate the integrity of the supporting structures. But this decision is also justified mainly for secondary structures, where high quality coating is not necessary. The colors of the created facings may differ, which further expands the possibilities for design. Additional areas of use:

-

wall cladding (combined, if desired, with building insulation in one cycle of work);

-

preparation of suspended ceilings;

-

production of sandwich panels.

Specifications

For the manufacture of a professional sheet of category C10, only steel that corresponds to a special GOST can be used. It has two subtypes: thin rolled products with only one zinc layer and galvanized products with additional polymer protection. The application of a polymer coating on one or both sides is usually due to the requirements of consumers and the intended purpose of a particular batch of sheets. The production of the profiled sheet itself is strictly subject to the norms GOST R 52246, introduced into use in 2004.

If you choose just such a product, and not manufactured according to the specifications invented by the manufacturers themselves, then there should be no risks when using it. Rolling is carried out in a cold state, but zinc is usually applied in the form of a hot melt. The total width of the structure is 115 cm by default, but useful - it is also working - the width will be only 110 cm. The weight is relatively small; 1 m2 of the area of the C10 profiled sheet weighs exactly 5 kg, that is, it is not difficult to hold it in your hands. Basic basic dimensions:

-

sheet length - 8 m;

-

the height of the corrugated sections - 0.01 m;

-

the total metal thickness is 0.4-0.7 mm, which is 100% determined by the additional layers used, and the thicker the profiled sheet, the more reliable it is usually (but manufacturers can slightly change these parameters - they must be recognized in advance).

Species overview

The so-called figured corrugated board is distinguished by a pair of edges prepared in production. It is considered the most attractive solution for the decoration of facade walls in private houses and public buildings. This design allows you to achieve a truly individual style and unique look. The top is equipped with the correct geometric pattern. Along with the wave, this pattern can also be represented by the "angular" type.

The choice between these two options is due to individual preferences. The slope of the edge can be almost any, if this point is discussed in advance with the supplier. When using curly corrugated board for a fence, an almost insurmountable obstacle is obtained even for trained people. Wavy corrugated sheet is often characterized as having a domed structure.

Outwardly, it looks like a picket fence, but the parts of the structure are interconnected.

Shaped corrugated sheeting, with proper installation and proper use, confidently serves for decades... Due to the lightness of the structure, fences can be erected without the use of complex foundations - and even practically without support at all. But it is necessary to understand that the curly sheets after the end of winter will have to be carefully examined, looking for even small defects. The slightest damage threatens the spread of corrosion, and therefore in many cases people use simple galvanized material, and not figured ones - it is more reliable, albeit less decorative. But it is even more reliable when the surface is covered with a special protective layer.

For financial reasons, polyester is very often used. The maximum coating thickness does not exceed 25 microns. However, such protection is not sufficiently resistant to mechanical stress. It will be necessary to transport and mount the profiled sheet with caution.

Often, similar structures are used in the middle lane and in a number of CIS countries.

Matt polyester, also known as purex, enhanced by the addition of Teflon. It is he who provides an attractive color scheme. The surface is relatively rough. The coating is resistant to ultraviolet radiation. The thickness of the protection usually reaches 35 microns, because it is technically impossible to apply it in a thinner layer.

Even thicker - up to 200 microns - is a layer of plastisol. It is very resistant to mechanical stress of various kinds. In some cases, such a product is marketed under the Solano brand. In appearance, the profiled sheet is similar to the skin.

It is necessary to take into account the insufficient resistance of plastisol to strong heating and intense ultraviolet irradiation.

They can also use:

-

PVDF;

-

pural;

-

quartzite;

-

polydexter.

Tips for choosing sheets

Professional sheet C10 can have an additional index: 899, 1000 or 1100. This is determined by the overall width of the structure. In most cases, consumers choose C10-1100. Such material is used in both residential and industrial construction. It is also worth clarifying:

-

availability of guarantees from the manufacturer;

-

declared service life;

-

features of the use of the material;

-

type of coating used;

-

the thickness of the profiled sheet;

-

the reputation of the manufacturer (reviews about it in independent sources).

Installation rules

When arranging fences made of corrugated board, one should not forget about the final bar. You can use both U-shaped and house-like finishing elements. The choice between the two is largely a matter of personal taste. But if there is a desire to simplify the process, then you need to limit yourself to the simplest solution in the form of the letter P. It will significantly reduce the complexity of installation.

When installing on a wall, a seal must be placed under the corrugated board. It is also used when the structure is installed on the roof.Such a sample perfectly protects against the ingress of liquid precipitation and snow. Also, thanks to it, dust will not clog under the corrugated board. Special seals are made of:

-

polyurethane foam;

-

wood-polymer composite mixture;

-

polyethylene foam.

It is also very important to dock the products correctly.... The overlap is selected in advance according to special rules. The length of the sheets should correspond to the length of the surface to be decorated. This will greatly simplify installation and solve many problems. It is categorically impossible to use welding and soldering for the installation of a profiled sheet - these methods will violate the integrity of the sheet and its anti-corrosion protection.

If the corrugated board is placed on an already erected wall, you will have to use mounting brackets. On these brackets, then guides in the format of the letter P are attached. There must be an air gap between the guides and the windproof film. The foundation must be equipped with waterproofing (most often with 2 layers of roofing material). You need to attach the corrugated board to the wall with self-drilling bolts with a sealing gasket.

To create an original visual effect, you can orient the corrugated board on the wall not directly, but in some other way. Of course, this does not impair its main technological characteristics. The insulation provided for the project is usually fixed with disc dowels. Above this insulation, it will be necessary to put an additional special water-impermeable film. After the installation of the main layers of the structure and the front material, additional parts are installed.

The comment was sent successfully.