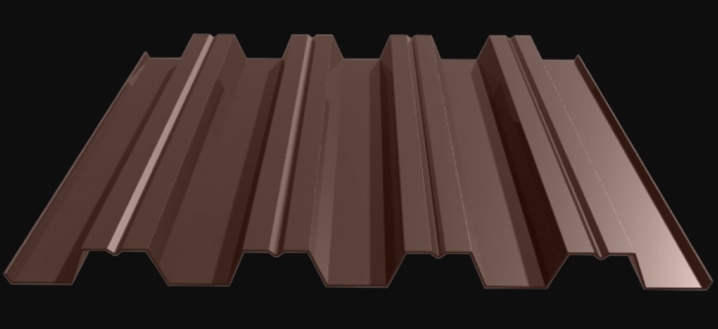

Features of professional sheets H57

The article describes the key features of the professional sheet H57. Attention is paid to the dimensions of the corrugated board and its bearing capacity. Analyzed other technical characteristics in accordance with GOST, as well as the nuances of installation.

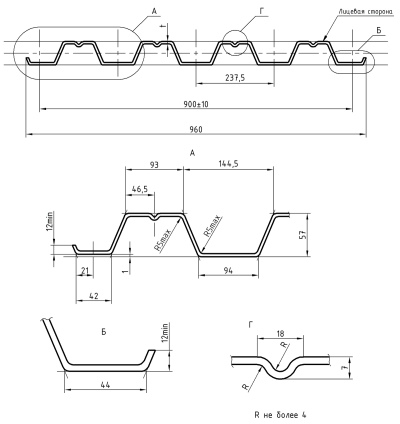

Specifications

This type of corrugated board - like its other options - is distinguished by high performance properties. In the production of such a product, it is imperative that they take care of high anti-corrosion resistance. Designers focus on the suitability of the corrugated board for repeated use (provided that the dismantling is done as carefully and sparingly as possible).

The main basic parameters are clearly fixed in the specialized GOST. Standard 24045 has been in effect in the Russian Federation since 2016. It is clearly defined in the document that the letter H in the grade of the H57 profiled sheet shows the main purpose - installation as a roof covering, and the overlap in this case must carry both the roof with insulation and the calculated values of weather influences.

The width of the shelves on the corrugations of the metal profile must strictly match. An exception is made only for the extreme shelves in the rows, but even there the width may differ by a maximum of 2 mm. The standard installation width is calculated as the distance between the center points of the outer shelves.

At one of the edges of the corrugated sheet profile, an element must be provided that ensures effective moisture removal under any weather conditions, even with a powerful downpour.

The dimensions of the roof sheathing are also strictly regulated in the standard. Its measured length is 3-12 m. At the same time, the exact value of standard products is always a multiple of 0.25 m (deviation even by 1 mm is strictly not allowed). But the measured length and multiplicity may change if it is stipulated by the agreement between the supplier and the client.

Obtaining a profile that is not covered with a paint-and-lacquer coating is carried out from coiled galvanized steel. By default, this is steel of the HP and PC categories. The standard thickness of the zinc coating layer is specified additionally in GOST 14918. A mandatory requirement is the maximum accuracy of the geometry of the rolled product.

A very important point, of course, is the bearing capacity of the H57 category profiled sheet. The step of the support when attaching the material H57-750-0.7 is from 3 to 4 m, and when using sheets H57-750-0.8, it also does not differ.

Applications

The material of the H57 category is characterized by its versatility and therefore can be used very widely in construction and installation work. The rigidity of such a profiled sheet is quite sufficient to confidently create reinforcement of a steel-concrete floor. But, of course, engineers play the main role here - they must calculate everything very carefully, and moreover, determine the admissibility of such a decision in advance. Other areas of use:

- the formation of roofs;

- preparation of permanent formwork;

- creation of floor slabs;

- installation of flat soft roofs;

- creation of steel frame structures;

- construction of fences (which are both durable and decorative).

Mounting

It is impossible to consider all the options for installing corrugated board H57 - and it does not make sense. Private customers use it primarily for roofing work. It is advisable to overlap the coating. The width of this raid is determined primarily by the level of inclination:

- from 12 to 15 degrees - this means that you need to provide a strip of about 0.2 m;

- with a slope of more than 30 degrees, you will have to limit yourself to a level of 0.1 m;

- on a flat roof - 0.3 m of raid is strictly required.

The lathing under the corrugated board is erected with a step of exactly 0.5 m.

A monolithic lathing is required to be done where it is adjacent to:

- window;

- endowe;

- chimney.

All wooden elements must be impregnated with antiseptic mixtures. They must also be protected from fire. The first row is made in such a way that a good overhang of about 5 cm is formed. A cornice strip is also mounted on the perimeter of the roof. To minimize material consumption, it is necessary to choose sheets that are maximally proportional to the size of the roof.

The comment was sent successfully.