All about transparent corrugated board

Decking is considered one of the most demanded building materials. It is in demand in the installation of enclosing structures, roofing and wall cladding. Its advantages include high mechanical strength, ease of installation, rust resistance and reasonable cost. The most widely used is a transparent polymer.

What it is?

Profiled sheeting is a sheet panel made of polycarbonate, PVC or composite material, in which trapezoidal corrugations are extruded along the long side. Such material is highly valued by owners of country houses for its high translucency - it is able to transmit up to 80-90% of the sun's rays.

The main advantages of corrugated board include several factors.

- Ease. Plastic sheeting weighs approximately 1.1 kg / m2. For comparison: the mass of metal profiled sheet is 3.9 kg / sq.m.

- Fire resistance. Plastic panels do not burn and do not emit volatile toxins when heated.

- Strength. Profiling allows you to mount such a coating on the roof without fear that during operation it will deform. Of course, only if you follow all the installation rules.

- Resistant to aggressive chemical solutions. The material is inert to the effects of salts, hydrocarbons, as well as acids and alkalis.

- UV resistant. Transparent profiled sheet is able to withstand the action of UV radiation for a long time without reducing its technical and operational characteristics. Moreover, it prevents them from entering the premises.

- Corrosion resistant. Plastic, unlike metal profiles, does not oxidize under the influence of water and oxygen, so it can be used even in rather harsh natural conditions, even on the coasts of seas and salt lakes.

- Transparency. A sheet of corrugated plastic can transmit up to 90% of the light flux.

- Availability for processing. A simple metal sheet can be cut exclusively with specialized tools. You can process plastic with the simplest grinder.

- Ease of installation. Plastic sheeting is often used to design "windows" in walls and roofs made of metal profiled sheet, since their color, shape and wave depth completely coincide.

- Aesthetic look. Contrary to popular belief, modern high quality plastic does not change its color and transparency parameters over time.

Polymer profiled sheet is considered one of the most practical translucent materials. However, it was not without its drawbacks.

Compared to conventional roofing materials, corrugated plastic does not withstand point loads. When servicing the roof, it is impossible to walk on such a covering: all work is carried out only after the installation of special ladders and supports.

Shorter term of use. The manufacturer gives a 10-year warranty on its corrugated plastic, although under favorable conditions it can serve for two decades. Nevertheless, this figure is lower than that of steel corrugated board. The metal coating will last up to 40-50 years.

Fragility in the cold. The lower the air temperature drops, the more fragile the corrugated plastic sheet will be.Even if the temperature regime does not go beyond the maximum permissible level (for polycarbonate it is -40, and for polyvinyl chloride -20 degrees), in frosty winters it can crack from impact.

Main characteristics

Plastic corrugated board is an impact-resistant material. The parameter of its specific viscosity corresponds to 163 kJ / m2, which is 110 times higher than that of silicate glass. Such material will not be damaged by a child's ball or hail. Only a large ice can pierce the roofing polyprofile, having fallen from a height - you must admit that this is difficult to attribute to common situations.

Plastic profiled sheet can withstand prolonged static load no worse. Due to the crushed waves, the material becomes rigid and retains its shape even under a pressure of 300 kg / m2 in case the load is evenly distributed over the entire surface. Due to this feature, PVC and polycarbonate material is often used for roofing in areas with increased snow load.

However, in this case, the slope of the slopes should be maximum so that a large cap of snow and ice does not appear on the roof structure.

Dimensions (edit)

Modern manufacturers produce corrugated board in several sizes. Depending on the wave height, it can be used as a wall or roofing material. The wall panels are shallowly profiled, which ensures the maximum working width of the panel. The wave height of such sheets usually corresponds to 8, 10, 15, 20 or 21 mm.

The roofing sheet has a large wave depth. This leads to a reduction in the functional width of the sheet. But in this case, its throughput increases - meanwhile, it is it that is the basic characteristic for all types of roofing materials. The waves of such profiled sheets have a height of 20, 21, 35, 45, 57, 60, 75, 80, as well as 90 and 100 mm.

Applications

Corrugated corrugated sheet is one of the cheapest and easiest ways to use natural insolation to illuminate a space. It does not block the visible part of the solar spectrum, but at the same time creates reliable protection from ultraviolet radiation. Basically, plastic sheeting is used to equip so-called windows in unheated attics, since classic dormer or dormer windows will cost much more. This is not to mention the high risk of their leaks if the junction points are made in violation of the technology.

but for a residential attic, such material cannot be used. If in the near future you are planning to turn your attic into a living area, then a transparent corrugated sheet will not be the best solution. It lets the wind through, this is especially noticeable in the autumn-winter period. And in addition, in hot summer weather, under the influence of direct sunlight, the corrugated board significantly increases the air temperature in the under-roof space. This microclimate is uncomfortable and can cause health problems.

A sheet of transparent corrugated plastic can be a good alternative to a fence. Typically, such barriers are installed at the dividing line in the private sector or between garden plots.

In accordance with the law, it is prohibited to install light-tight solid fences in such areas, since this can create a darkening of neighboring areas.

In previous years, they used a netting or picket fence. But they also have their own minus - they do not in any way interfere with the entry of outside pets into the site and the exit of their own. Transparent plastic profiled sheet solves two problems at once. On the one hand, it does not interfere with the passage of light, and on the other, its slippery coating will not allow even tenacious cats to climb.

The translucent corrugated roofing will be the best choice for decorating terraces, loggias, as well as verandas and gazebos. Plastic sheeting restrains ultraviolet light, but at the same time leaves the opportunity to enjoy the gentle light and comfort of the sun's heat without the danger of getting burned. The transparency of this building material visually reduces any structure, making it lighter, lighter and more airy. With this approach, the gazebo will look harmonious even in the smallest areas.

Plastic corrugated board is a slippery material. If the slope of the roof exceeds 10%, then moisture on the surface will not linger and will begin to carry away all pollution. Even light rain will clear such a roof, maintaining its transparency without any additional maintenance. Due to the high light transmittance, the profile corrugated sheet becomes indispensable for the construction of greenhouses, winter gardens and greenhouses.

In addition, the material can be used:

- for glazing sports facilities, covered walkways and skylights;

- to create inserts of noise-suppressing screens near a busy highway;

- for the construction of partitions in office centers and production halls.

Polymer profiled sheet is used for some types of interior decoration of living quarters, for example, for sewing shower doors. It fits harmoniously into any modern interiors. It looks quite stylish, has a slight thickness and is extremely durable.

Installation features

Most often, a plastic profiled sheet is used for roof installation. This work is simple, any person with minimal skills in construction and finishing works can handle it. However, it is important to adhere to certain rules.

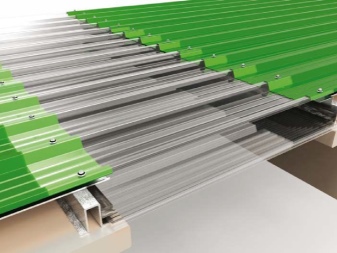

The profiled sheet is laid at an air temperature of +5 to +25 degrees. The sheets should be fixed perpendicular to the crate, in rows, from the bottom of the roof, moving up.

Work should start from an area opposite to the prevailing winds. For example, if the south wind predominantly blows at the construction site, then you need to start laying the profiled sheet from the north.

It is important to correctly draw up the overlap. For longitudinal fixation, it captures one wave, in windy places - two waves. The transverse overlap should be at least 15 cm, on roofs with a slope of less than 10 degrees - 20-25 cm.

During work, you should not step on the layers of the polyprofile with your feet - this leads to their deformation. Before starting work, you should lay a substrate (a fiberboard sheet, plywood or a board at least 3 meters long), it will allow you to redistribute the load as evenly as possible. Mounting of the profiled sheet on the roof is done in the upper part of the wave, on walls or fences - in the lower part.

Before fixing the self-tapping screws, it is necessary to compensate for thermal expansion. For this purpose, a hole with a diameter of 3-5 mm is drilled in the place of fixation. Despite the simplicity and ease of work, try to get at least one assistant. This will significantly speed up your work, especially in the area of lifting material to the roof. And besides, it will make it as safe as possible.

The comment was sent successfully.