Junction strips for corrugated board

The use of abutment strips for corrugated board is a very important topic from a practical point of view. These products are divided into upper and lower, and their sizes also differ. It is imperative to figure out how to install the abutment strips.

Appointment

The visual beauty of the profiled sheet has long been appreciated by ordinary consumers and even designers. However, not everything is as simple as it seems - in a number of places, when installing it, aesthetic problems are formed. For example, it is impossible to ensure - even with the most careful installation - the preservation of the integrity of the joints:

-

with chimneys;

-

pediments;

-

capital walls;

-

ventilation pipelines;

-

antenna masts and other structures.

But integrity violation is not just a visual issue. The penetration of water from the outside negatively affects the condition of the roofing structures. It is these problems that are able to successfully solve the abutment strips for corrugated board.

In addition, they ensure the reliability of the hitching of sheets that would otherwise be pulled apart and could not be aligned. Of course, such strips are also judged by their decorative appearance.

Description of species

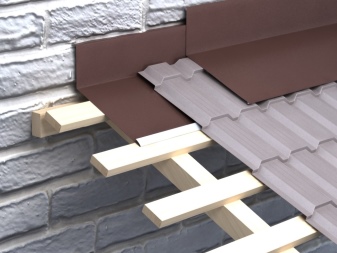

Outwardly, the structure looks like a metal corner. Its height is chosen arbitrarily by the developers. Experts distinguish between upper and lower planks. The latter are used mainly for passing chimney pipes or ventilation. The upper structure in this version has an almost exclusively decorative role.

But everything changes when it comes to the places where the roof is attached to the walls of the house. There, the top bar turns out to be the basic waterproofing element. It depends on it, first of all, whether the under-roof space will be protected from water ingress. Sometimes it is necessary to cover a large roof area. In this case, the plank elements are placed with an overlap of at least 10 cm, and ideally even more. Such a moment should certainly be taken into account when determining the desired block sizes and their total number.

There is a universal rule that cannot be broken. It says that the tops should overlap the bottoms, not the other way around. It is this solution that guarantees the efficiency of precipitation discharge and excludes their leakage into the lower levels of the roofing cake.

You can even distinguish the lower planks from the upper ones simply by their appearance. The two edges of the corner are equipped with longitudinal bends along the entire length, which is not available in the other version.

Installation instructions

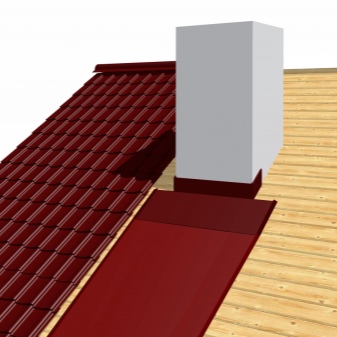

Before installing the sheets near the smoke or ventilation duct, put an inner apron. It is formed from the lower planks. Installation starts from the bottom wall of the chimney. A so-called tie is attached under this wall, allowing water to flow out. Then they do this:

-

put the side parts (along the lower bar they should go with an overlap);

-

they put an extension on the upper sides of the pipes - the overlap is already in relation to the side parts;

-

fold the edge of the horizontal upward (this eliminates the very water seepage);

-

before attaching the extensions, try them on to the wall, leaving a line along the upper edge;

-

a strobe is driven along this strip, which will have to be cleaned of dust and rinsed;

-

the edge of the strip is laid in the recess;

-

insulate it with a sealant and press it with self-tapping screws (make sure that the vertical falls on the wall, and the horizontal - on the crate);

-

carry out the installation of a profiled sheet;

-

lay out the outer apron using the upper adjoining elements (with a corner without edge bends);

-

attach the joints of the upper planks to the profiled sheet using rivets.

The comment was sent successfully.