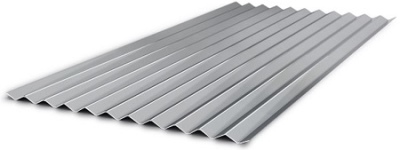

All about corrugated sheets

The corrugated sheet as a material for the roof has convenient dimensions, can be easily and quickly mounted on verandas, terraces, and capital buildings. Metal and plastic, aluminum, galvanized and steel versions of such coatings are in demand in the decoration of private housing, commercial facilities. A detailed review of this material will help you learn about how corrugated "wave" sheets differ from ordinary metal profiles, where they are used.

Peculiarities

Modern roofing, fence and wall materials come in many varieties. Corrugated sheet, the release of which is regulated by the requirements GOST 9045-80 for sheet steel and GOST 14918-80 for galvanized steel, counts one of the most affordable and reliable options... This material is produced by cold rolling, stretching through special shafts. Wave structure is the main difference between a corrugated sheet and a profiled one with a trapezoidal, rectangular or sinusoidal relief shape. For this feature, it is also called euro slate, since the external similarity of materials is quite large.

A classic corrugated sheet is always metallic, with a base of ferrous or non-ferrous metal. Outside, there may be an additional protective and decorative coating. Corrugated sheets belong to the wave type of profile, therefore, the height of their ribs does not exceed 20 mm. This allows you to make the material more attractive in appearance, but increases the requirements for the strength of the base, the step of the lathing or the lag.

Consider the distinctive characteristics of corrugated sheets.

- Wavy continuous profile. It significantly lightens the structure and makes it visually attractive.

- Versatility... On the facade, such a coating looks like a painted or tinted block house. The roof resembles slate.

- Small thickness with high rigidity... This allows the use of a rarer lathing without losing the bearing capacity of the material.

- Ease of installation and transportation... Even 1 person can handle light sheets.

- Long service life. On average, manufacturers set it at 50-70 years.

- Reliability... The surface of the sheet can withstand a load of up to 250 kg / m2. This allows it to be used as a roof covering or canopy, even with significant snow loads.

- Adaptation to different climatic conditions. At any level of humidity, the coating retains the characteristics declared by the manufacturer.

- Reusability... The sheets that have served their time as part of temporary structures can be used for other purposes.

- Wind resistance... The sheets are quite thin, so they have little windage even when used as part of fences.

- Compatible with all types of sound insulation, thermal insulation. The material is easily adaptable to specific conditions; both fibrous and foam or similar insulation materials are well combined with it.

The disadvantages of corrugated sheets can be called a small range of products, increased consumption of sheets during installation. Otherwise, this material fully justifies the expectations placed on it.

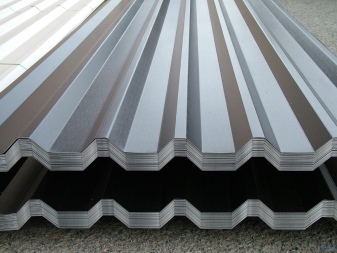

Views

All varieties of corrugated sheet are usually divided into categories according to the type of base, the presence of an additional decorative and protective coating.

- Steel sheet metal. It does not have a protective coating, it is easily corrosive.The material needs additional decorative coating. This option is suitable for creating internal partitions in industrial and commercial buildings, cladding warehouses, hangars, garage premises.

- Galvanized from ferrous metal. Well protected from external atmospheric influences, such a corrugated sheet is suitable for covering external walls and roofs, creating fences and temporary fences. The material has all the advantages of galvanized metal, and the "wave" profile gives it additional rigidity and strength.

- Polymerized colored. The most expensive steel sheet option. It has a protective coating that is resistant to wear and tear. Polymer dyes include pigments that give the material the desired hue. The color gamut is quite wide, the sheets serve for a long time, they are not afraid of UV rays.

- Aluminum wave corrugated sheet. This is a stainless version of the material that has a higher price than steel counterparts. Such a sheet is sold uncoated, but it can be self-painted in various colors. High resistance to weathering is combined here with low weight of structures, durability, no risk of metal damage by rust.

- Plastic profiled sheet "wave"... Most often we are talking about a product made of monolithic polycarbonate. Its sheets are made in the same shapes and sizes as steel, made completely transparent or colored, with tint. Such products are used as sheathing of awnings and canopies, they are inserted into the roofs of attics to ensure the maximum flow of light into the interior.

It is worth considering that corrugated sheet is also sometimes referred to as specialized types of packaging cardboard with a ribbed surface. Such options are used as a soundproofing layer inside the house. In addition, examples of cardboard-like corrugated sheet can be seen as packaging for electric lamps.

Dimensions (edit)

The corrugated sheet has a certain list of standard parameters that do not change depending on the choice of material. It is characterized by the following dimensions:

- thickness 0.3-1 mm;

- length 2000-2500 mm (from 6 to 12 m in rolls);

- wave height 15-18 mm;

- installation width 920 or 1150 mm, useful 880-1080 mm.

These characteristics remain unchanged. The material has strictly defined parameters, provides opportunities for convenient joining and installation of corrugated surfaces.

Applications

Corrugated steel, aluminum and polymer sheets are widely used. Light translucent structures are made of it in the form of awnings, canopies, balcony rails. Aesthetic roofs for terraces and verandas, greenhouses, as well as inserts that allow you to fill a dark attic without windows with light are obtained from polycarbonate corrugated sheet.

Metallic varieties have an even wider range of uses. Such a corrugated sheet can be used as a base:

- for roofs, laid on a solid or rafter base;

- for garage door leaves;

- for exterior wall decoration;

- to form a protective and decorative coating;

- in the organization of refractory partitions;

- in the formation of solid shield-type fences;

- in the demarcation of the site, the planning of its territory;

- in the design of balcony parapets;

- for cladding the frames of buildings and structures inside.

The custom profile allows the material to be tailored to suit a wide variety of applications. In the presence of a decorative polymer coating, corrugated sheets look great as part of frame commercial structures - pavilions, trays, shopping malls.

And also the material is successfully used in the production of sandwich panels and sets of houses.

Selection recommendations

When buying corrugated sheets, it is very important to pay attention to the main parameters and criteria that matter. The main point will be the compliance of the product with standards. The signs of a manufacturing defect in this case include:

- chips on the decorative coating;

- dents and other damage;

- white bloom on a galvanized surface;

- uneven color;

- the presence of darkened areas and spots;

- traces of rust.

Matters and overlapped area. Usually, the material is produced in sheets no more than 2.5 m long, but rolls of 6 or 12 meters are supplied on an individual order. This option is suitable if you need to install a corrugated sheet with a continuous tape with a minimum of joints.

The purpose of the material is also an important factor.... For example, even uncoated steel corrugated sheet is suitable for interior work. Temporary awnings and gazebos, porch canopies look good in a transparent design. Here, polycarbonate sheet with a corrugated wave-like profile is suitable. For fences, roofs, exterior walls of buildings, only coated varieties are used.

In addition to decorative functions, they also provide additional anti-corrosion protection of the metal, prevent its early destruction under the influence of weather factors.

The comment was sent successfully.