Features of socket head screws

According to their purpose, all screws can be divided into two broad categories: fastening and installation screws. Fasteners come in several varieties, but the most popular in this category are socket head screws.

They are used in certain areas, and it is recommended to use special tools for unscrewing and screwing them in.

general description

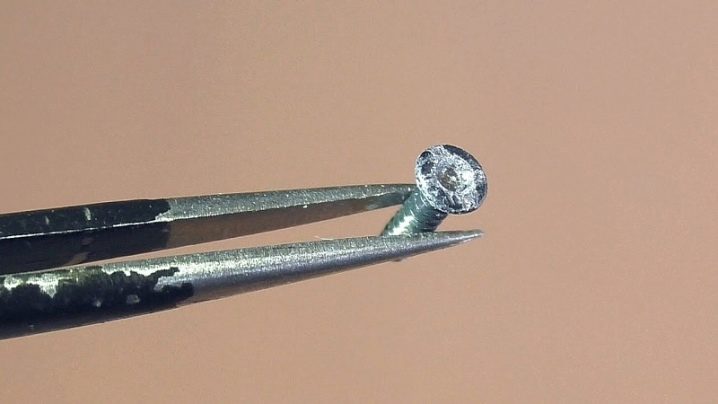

Socket head screws are not a modern invention. They were first produced and used back in 1936, so they are almost 100 years old. It goes without saying that since that time these fixing accessories have gone through several stages of modernization. Modern ones differ from their predecessors both in the material of manufacture and in appearance. Outwardly, such screws practically do not differ from others. The base is presented in the form of a threaded cylinder. The peculiarity is that the screw has a hidden head. Connecting elements of this type are made from the most durable steel. This is necessary so that they can withstand the imposed load.

Among the features of such fasteners should be highlighted:

- durability;

- relatively low cost;

- strength;

- usability on certain surfaces where you want to hide the fastener.

There are many advantages to using this type of screw in different industries. Let's list them.

- To screw in such a fastening tool, it is enough that there is a hole on the surface only for the barrel itself. There are no hats in such hardware, so the extra extra space will not come in handy in this case. In addition, the key does not overlap on the head, but is inserted, which also does not require space.

- It is quite easy to lick the slot of an ordinary bolt if such a fastener is not used for the first time, initially its quality does not correspond to the declared one, or the actions of the master were not entirely correct. The slot of a screw with an internal hexagon is much more difficult to lick off, since initially such fasteners are made of a higher quality and durable material. Even with the wrong actions of the master, the tool itself is more likely to be damaged than the fastener.

- For socket head bolts, a specialized wrench must be purchased. Compared to a spanner or open-end wrench, such a tool is slightly cheaper. This point can also be attributed to the benefits.

- The head of such a fastener has no sharp surfaces.

- Bolts of this type are very convenient to use in hard-to-reach places on machined surfaces.

Strength for this type of bolt is very important because it allows the screws to be removed and reinstalled without damaging the surface itself.

The main types and their characteristics

There are several types of screws that differ from each other not only in appearance, but also in purpose. The current GOST defines the following categories.

- DIN 912 Is one of the most common hexagon socket screws. Distinctive features in this case are considered: cylindrical head, full or incomplete thread. The size range is presented in lengths from 4 to 600 mm. The range of diameters is from M2.5 to M64.

- DIN 913 - means a set screw with a flat end. Length - from 3 to 160 mm, diameter - M3-M24.

- DIN 914 - adjusting, locking, with a pointed tip.

- DIN 915 - screw with an internal hexagon socket head.

- DIN 916 - with an internal hexagon and a drilled tip.

In order to better understand how to choose the right screws, you need to familiarize yourself with all the differences. So, one of the defining criteria is accuracy class of fasteners. Class A screws are the most accurate. Accordingly, in terms of cost, they will be the most expensive. Further, the quality of accuracy decreases, but this does not mean that such screws will be unreliable connecting elements.

The sizes can also be very different. The smallest diameters are 2.5 and 3 mm. Further, the size increases. The most common options are: M4, M5, M6, M7, M8, M10, M12. The head is also available in different versions: semicircular, round, reduced, high and low. There are screws with a flange and slot. Their use directly depends on the design to be processed.

You should also pay attention to the tip, as some screws are for metal, others are more specialized in wood. For example, an M8x70 socket head screw is ideal for fastening wooden surfaces.

Applications

The socket head screw is the most durable connecting element, therefore it is used in various fields. The most common applications include:

- construction;

- mechanical engineering;

- all kinds of industries.

At the household level, such screws are often found in cabinet furniture. These can be wardrobes, beds, computer desks, dressers. Bolts are not only supplied at the wholesale level, they can be purchased individually from specialized stores. Fastening accessories may differ by manufacturer, cost, parameters.

How to unscrew without a key?

Sometimes, when working with fasteners of this type, non-standard situations may arise. One of the most common is associated with the so-called licking edges on the cap. This leads to the fact that it becomes more difficult to unscrew the bolt several times. This problem can be encountered by both experienced craftsmen and beginners. When the edges are licked, the tool starts to scroll, while the fastener itself remains stationary. There are several reasons why licking occurs:

- using old tools or improper quality screwdrivers and wrenches;

- improper use of a screwdriver or key (this often occurs among inexperienced craftsmen);

- the fastener itself is initially of poor quality (fragile material that easily deforms under any mechanical stress).

If, during the process of unscrewing the socket head screw, the working tool begins to slip, you should not immediately panic. The first thing to do in this case is to change the rig. It is possible that the reason lies not in the licking, but in the improper quality of the screwdriver (key). If this does not help, then you need to proceed.... There are several ways to twist.

Hex keys are of two types: S-shaped and L-shaped in shape. If such tools are not available, then their analogue can be a bolt with an external hexagon.

The only condition that must be taken into account is that the bolt and fasteners must match each other in size.

If the dimensions are the same, then a specific tool must be made from the bolt. To do this, several nuts are screwed onto the rod (3-4 pieces are enough). They need to be jammed, grasped well with an open-end wrench and secured. The tool is ready. Even if he did not cope with the task, then you can use one of the methods listed below.

- If the diameter of the bolt is quite large, then the brute force method can be used.... To do this, you will need to use additional tools: a chisel and a hammer. The first must be positioned at an angle, and then hitting it in the direction of unscrewing the bolt. Of course, in this case, one should not hope for the safety of the hardware, but it will be removed from the surface.

- Small hardware can be unscrewed using a spanner or spanner... This is only possible if the tool itself has small notches.

- The licked screw can be unscrewed using a special tool - a wrench. If, in this case, also strikes, then additional weakening of the fasteners will occur.

If none of the above methods worked, and the fasteners still need to be unscrewed, it is recommended to switch to more efficient, but laborious methods. To do this, you will need to use a drill and a set of drills of different diameters. To begin with, the thinnest drill is taken. A small hole should be made directly in the center of the hardware. Then the same steps must be repeated, but each time the drill diameter must be increased. In the end, nothing will remain of the fasteners except metal chips.

If the cap of the licked bolt is not deepened, but protrudes above the surface, then you can use ordinary pliers. With their help, you need to grab the head of the hardware and, performing swinging movements, gradually pull out the screw. All actions in this case must be done carefully so as not to loose the hole. Otherwise, it will be problematic to fix a new hardware in this place later.

Allen screws are the most common and reliable fasteners, so they have found their application in a variety of areas: from everyday life to industry. In order to work with this type of fasteners as simple and comfortable as possible, it is recommended to choose high-quality material at the stage of purchase. When working, it is important to use tools that match the dimensions of the hardware.

It is recommended to buy screws exclusively in a trusted store. When choosing, you should pay attention to the manufacturer, the appearance of the bolts, cost and other important characteristics.

The comment was sent successfully.