All about dowels for hollow structures

Hollow brick, MDF, drywall, tongue-and-groove plates have special properties, and when you need to attach any structure to them, it is impossible to achieve high-quality fasteners with a simple dowel. A porous or hollow base does not allow to withstand high mechanical loads. As a result, a self-tapping screw or other unsuitable fastener can simply fly out of the socket, leaving behind a torn hole. In working with such bases, special fasteners are used - dowels for hollow structures.

Features and purpose

The uniqueness of such a dowel is that it has a multi-section sleeve structure. The fastener initially has a metric-type screw with a Phillips head, ring, and the like.

The hollow core dowel is easy to install. This can be done with a screwdriver or assembly pliers. Due to its use in hollow materials, the fastener has a large openable thrust wing area, which ensures the reliability of fixation. Provision is made for the reuse of the screw after it has been removed from the dowel. The remaining dowel does not lose its fastening properties.

The assortment of hollow wall plugs includes more than a dozen types. It can be difficult for a layman to make a choice if he does not know what exactly is right for him in a particular case.

Some of them require pre-drilling, others are self-tapping type.

For hollow walls

Such a dowel is made of nylon, zinc-aluminum alloy, galvanized steel. Fastening technology is:

- programmable deformation;

- thread and programmable deformation;

- thread plus swivel.

Some are reusable, but most are single use.

To install the dowel with pre-drilling, use a drill (drill or screwdriver).

For tongue-and-groove plate

This type of fastener is also made of metal or nylon, has a two-piece design - spacer and non-spaced. The spacer part changes its configuration during installation. A dowel of this kind can have a limitation in the form of a cylindrical or round cuff, which will not allow it to fall into the hole. According to the method of installation, fasteners are divided into driven and screwed. Dowels for GWP through-type have an elongated non-expansion part. The spacer type is installed in the wall for its entire length.

Types of fasteners for a gas silicate block, aerated concrete and aerated concrete:

- frame;

- nylon;

- plastic;

- metal.

This choice allows the use of dowels in accordance with the forthcoming load. For lightweight structures, nylon or plastic are ideal. Heavy equipment and furniture are attached to metal dowels. This is the most durable and fireproof type of fastening.

Basically, these fasteners have a protective sleeve.

Species overview

The most common method of mounting fasteners is friction fastening. When working with fiberboard or drywall boards, other hollow materials, this method is not suitable. With drywall, the spacer technology will not work, and in the case of GWP, you can miss and fall into the void, and fixation will not occur. Therefore, they choose fasteners with the principle of action - fastening with a form.

- Molly metal anchor with screw... The anchor is inserted into the drilled hole with a bushing with slotted tabs, which expand when the bushing is pulled to the rear surface of the panel.

- Butterfly dowel - polyamide and steel rod with metric thread. By tightening the screw, the petals are tightened and expanded. The length of the screw allows the use of fasteners with thicker surfaces, with several sheets of drywall.

- Dowel Fischer PD has a tapered spacer and is mounted in the PPG and panels. While screwing in, the cone is tightened, and it “zips” tightly, while expanding the petals. The choice in favor of this type of fastener is made when working with sheet material from 6 mm.

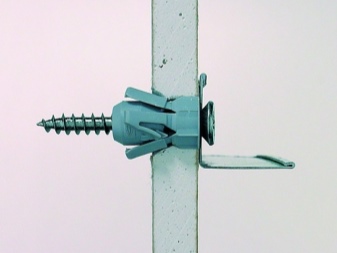

- Metal dowel for suspended structures - chandeliers, paintings, shelves, light wall cabinets and more. Fasteners are selected according to the thickness of the material and the non-expansion zone. Install with a screwdriver or special pliers. Reuse is possible. Consists of a collet with spacer and non-spacer zones, as well as a screw with a metric thread, a ring or a half ring.

- Special dowel. Its purpose is to fasten lightweight structures in hollow bricks, porous concrete foundations. Has a polypropylene sleeve with a countersunk rim, notches all over the surface and a spacer mustache. The metal nail has a thread.

- Dowel nail refers to special-purpose dowels, used for fastening structures and objects to solid materials - brick, concrete. It is hammered not only into the dowel, but also directly into the base. It is more often used under the finishing plating for the installation of auxiliary rails.

Dimensions (edit)

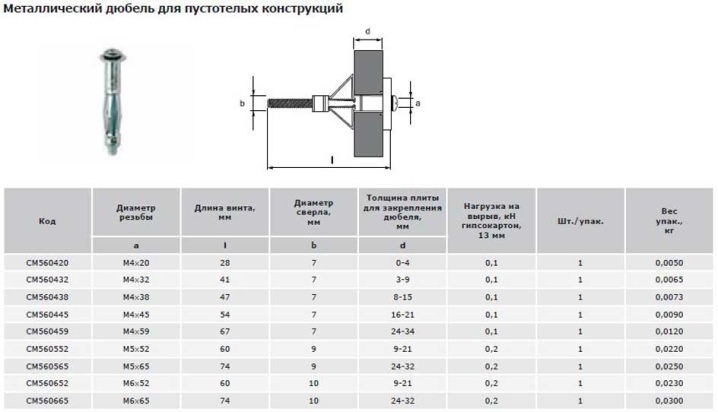

For a high-quality installation, you must choose the correct size fasteners. Standard sizes are 4, 5, 6, 8 mm. 10 mm fasteners are used much less often. The length of the product depends on the diameter: if, with a diameter of 10 mm, it is equal to from 100 to 200 mm, then with a diameter of 6 mm, it will accordingly be from 35 to 80 mm. Each manufacturer has developed its own standard size, but general values are still available. They are given in the table and will help you navigate the choice. In addition, for the fastener to hold firmly, its size must match the size of the slab or brick.

Metal dowels marked M6x52, M6x65 refer to fastening hardware... Their purpose is the installation of lightweight structures, drywall, chipboard to solid brick, wild stone and concrete. They have a limiting side, sharp teeth and slotted elements of the sleeve.

Mounting

Experienced technicians use a proven installation method. Mark the locations of future holes for fasteners. This can be done with a pen or pencil. Then, using the tip of a knife, small indentations are scratched at these marks. They will help the drill to stay on the mark. The diameter of the drill is selected exactly with the diameter of the dowel so that it fits tightly into the hole. Loose fasteners are a sign of poor installation.

Similarly, the hole depth and the length of the fastener should be suitable in size, the same criteria apply to the screw and dowel. Holding the drill at an angle of 90 degrees, at low speed, drill a depth of 1 cm using a shockless method. Then increase the speed. If the drill does not have a depth gauge, then a mark of the desired length is placed on the drill itself.

The finished hole is blown to remove dust and crumbs. The dowel is carefully driven in using a hammer as an impact tool. When installing the wall cupboard fastener, a 2 mm gap is left when screwing in the screw. For other types of fastening, the screw or nail is recessed flush with the surface.

Compliance with all the necessary conditions will allow for high-quality and reliable installation of structures.

You can find out which dowel to use for hollow bricks from the video below.

The comment was sent successfully.