Choosing the size of the footwear

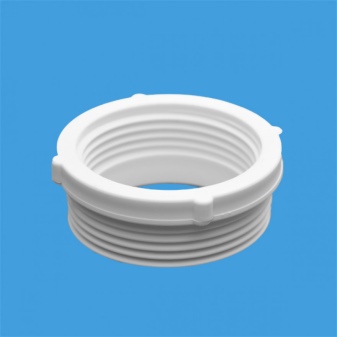

A fitting is a threaded adapter (fitting) that has the shape of a cylinder with a threaded through hole and an external thread at one end. The outer and inner threads are always different in diameter (there are no cases with the same hole diameter, for example, 1x1). The type of thread can be the same or different. Double thread allows connecting parts of different diameters, changing from one thread to another.

There are furniture and renovation fittings. The most popular varieties are those that are used in the assembly of various pipelines and plumbing systems.

Plumbing fittings are metal and plastic - for different types of pipes. The material and wall thickness determine the flow rate, maximum pressure and temperature for which the system is designed. To prevent the part from becoming a weak link, it is important to choose the right size and characteristics. Consider what they are.

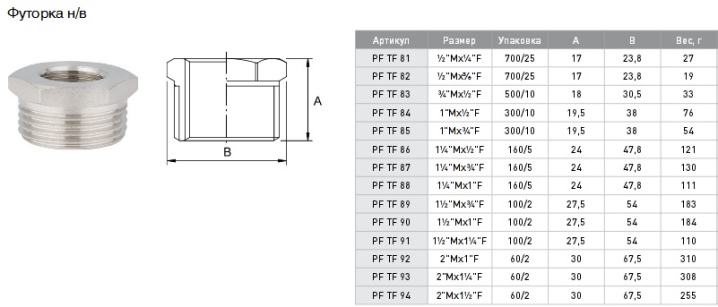

Dimensions of metal cases

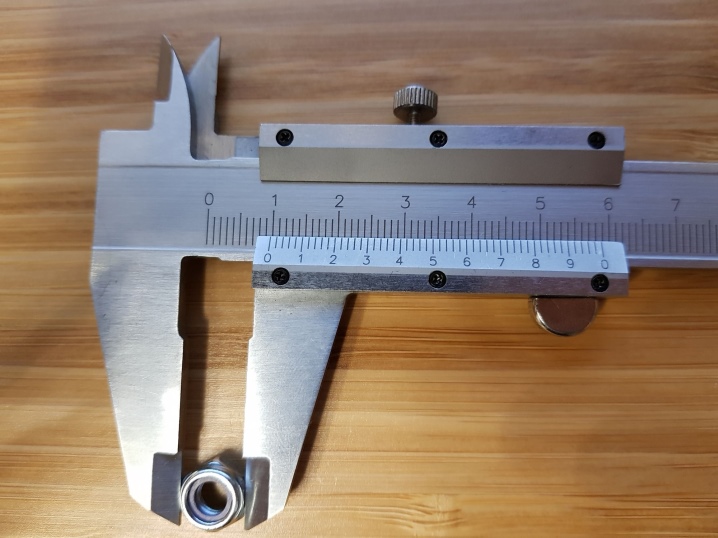

Threaded connections are standardly used for pipes up to 50 mm, so a typical metal sleeve is made from ½ to 2 inches (8 to 50 mm) in diameter. Wherein pipes and adapters up to 50 mm made of cast iron and steel are marked by the inner diameter without taking into account the wall thickness.

To find out the outer diameter, you need to add twice the wall thickness to the inner diameter. Pipes over 50 mm, as well as from other materials (copper, plastic) of any size, are marked by their outer diameter.

The optimal proportions depending on the size of the footwear, its pressure class and material are specified in GOSTs.

The dimensions and weight of cast iron footwear are regulated by GOST 8960-75. The minimum size is 10x8 mm (3/8 by ¼ ") weighing 0.019 kg, the maximum recommended is 65x25 mm (2 1/2 by 1 1/4") weighing 0.508 kg. GOST does not recommend using options with a large diameter, although it admits that they can be manufactured - for example, 3 by 2 inches, 3 by 21/2, 4 by 3 inches. Cast iron fittings are distinguished by the lowest cost price and high reliability, they perfectly tolerate contact with hot water and steam (up to 175 ° C). They are used for the installation of steel and cast iron pipes for gas, heat and water supply in residential buildings. You cannot do without them when installing a cast-iron radiator. The most common dimensions of the radiator box are 3/4 by 1/2 "(20x15 mm) or 1 by 1/2" (25x15 mm) - for connecting the battery to 1/2 "pipes, which are most often used in apartment buildings.

In terms of resistance to mechanical stress and aggressive media, cast iron is much inferior to steel. Therefore, where increased strength is required, steel fittings with special coatings are used. They can even withstand contact with acids and alkalis, high pressure (up to 16-25 MPa). Such products are manufactured in accordance with GOST 3262-75. And also American and European (ASME, ANSI, MSS, DIN) standards are often used for steel sleeves.

Parts made according to different standards can be used in one system, since unified pipe thread sizes are used, the nominal size parameters are compatible.

Steel sleeves for domestic applications are available in nominal diameters from 10x8 mm (3/8 by ¼ ") to 65x50 mm (21/2 by 2"). The length of the threaded section is from 13 to 28.5 mm, depending on the size of the case, the total length is from 17.5 to 39.5 mm.

The wall thickness depends on the standard (the Russian standard divides products only into 3 pressure classes, and the international ones give a wider gradation so that fittings and pipes are better suited for different operating conditions). For example, the minimum thickness of pipes and fittings with a typical diameter of 20 mm (3/4 inch) in accordance with GOST: light - 2.35 or 2.5 mm, ordinary - 2.8 mm. ASME: 10S series - 2.11 mm, STD series - 2.77 mm, 40S series - 2.77 mm.

And also, footwear with metric thread is made of steel. In pipelines for household use, they are used to connect the nozzles of various devices, meters, hoses. Special types of footwear with metric thread - furniture and repair footwear. Furniture ones are made for reciprocal steel hardware (screw, self-tapping screw), can be driven in, equipped with a spacer mechanism. Repairs represent special inserts for the restoration of stripped threads. As standard, metric threads are available in sizes from M4 to M20. M6, M8, M5, M10, M12 and other options are in demand. When marking, the thread pitch is also indicated, it can be 0.5, 1 or 1.5 mm. For example, the actual size for the restoration of the plug thread in the car is indicated as follows - M10x1, M10x1.5. Sometimes for furniture footwear, a not quite standard designation is used, where the second number indicates not the thread pitch, but the length of the footboard - M6x10, M8x14.

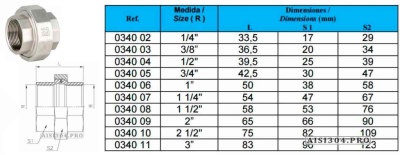

When installing household utilities, footwear made of copper with pipe threads can also be used, and most often they use not pure copper, but its alloy - brass. Brass fittings are lightweight and have an optimal price-quality ratio, suitable for joining plastic, metal-plastic and metal pipes. The metal parts of the combined footwear are also most often made of brass.

The parameters of copper, brass adapters and inserts are determined by GOST 32585-2013. They are made for standard pipe threads and are designed for a pressure of not more than 16 MPa, normal operating conditions in domestic pipelines. The wall thickness depends on the size of the footboard. The smallest brass piece 10x8 mm (3/8 by ¼ ") can be as little as 1 mm thick uncoated, the cast case measuring 65x50 mm (21/2 by 2") is 2.4 mm. The length of the thread, depending on the size of the foot, is from 4.5 to 17.5 mm.

For combined fittings, the parameters on the metal part of the threads are indicated according to the standards for metal threaded connections, and the parameters of the plastic part are indicated according to the standards for plastic parts.

Dimensions of plastic elements

The diameter of the through hole of plastic elements is made in accordance with GOST 18599-2001 according to uniform standards for metal and plastic pipes, so that elements made of different materials can be interconnected.

When marking plastic threaded connections, the bore diameter and parameters of the mating pipe thread are indicated in the same way as for metal fittings.

For example, the marking of the foot 1 by ½ inch denotes a part with dimensions of 25x15 mm. The parameters of non-threaded plastic elements are indicated only by the outer diameter - taking into account the wall thickness. This must be taken into account to avoid confusion. At the same time, it is not recommended to use threaded connections for plastic pipes with an outer diameter of more than 63 mm.

The wall thickness of the plastic fitting depends on the design pressure and is determined by the SDR factor. The smaller it is, the thicker the pipe wall, and the greater the load and pressure it can withstand. For example, pipes with SDR 41 can withstand up to 4 atmospheres and are suitable for the installation of a gravity drainage system, and to create a low-pressure pipeline, pipes with SDR 11-17 are already required. The wall thickness for pipes with SDR 11 and an outer diameter of 20 to 63 mm will be in the range from 2 to 4.7 mm. Values for other pipe classes can be found in special tables. The fitting is selected so that its SDR parameter is no more than that of the larger of the pipes to be connected.

The assortment of sizes of plastic sleeves is very wide and allows you to find an adapter for a variety of tasks. - from connecting a washing machine, a water meter to the installation of complex transitions and pipe connections for heat, water, gas supply in a private house or cottage.The most common sizes of footwear that are used in the installation of heating systems are 32x25 mm and 40x32 mm, fittings 25x20 and 25x15 mm are used for the installation of water pipes. And also when installing plumbing systems, fittings with parameters 50x40 mm (2 by 1 ½ "), 3x2" are in demand.

Nuances of choice

The main parameters when choosing a footboard are dimensions and class of operation. But there are a number of other nuances that should not be overlooked.

- It is imperative to take into account not only the diameter, but also the type of thread (cylindrical, conical, metric). It can be found in the documentation or measured.

- The total length of the threaded section at the fitting must not be less than the length of the threaded branch pipe of the connected device or the end of the pipe. At the same time, for a reliable connection, there should be at least 5-7 thread turns, and the optimal parameters are indicated in GOSTs for each standard size.

- For maximum compatibility, it is better to buy all pipes and fittings of the same brand and from the same manufacturer - such equipment is made according to uniform standards and is already fitted.

- To switch to the desired size or thread standard, sometimes you may need not one, but several futoroks connected to each other like nesting dolls.

- Material compatibility must be considered. For cast iron pipes and batteries, only cast iron adapters are suitable, for copper pipes - from brass or copper. For plastic, an adapter of the same type of polymer as the pipe must be used.

- The fitting must be clearly marked with information about the size and class of use. Many experts mistrust the "unnamed" futorki.

The comment was sent successfully.