Varieties and installation of furniture fittings

A futorka is an important piece of furniture fasteners, necessary to create a threaded fastener, without which it is impossible to imagine modern collapsible and functional furniture. The part is installed hidden and invisible from the outside, but it is she who holds the entire screed on itself. In order for the footwear to cope with the load, it is very important to choose the right dimensions, the material from which it is made, and also correctly carry out the installation. In this article, we will consider the types and installation of furniture fittings.

What it is?

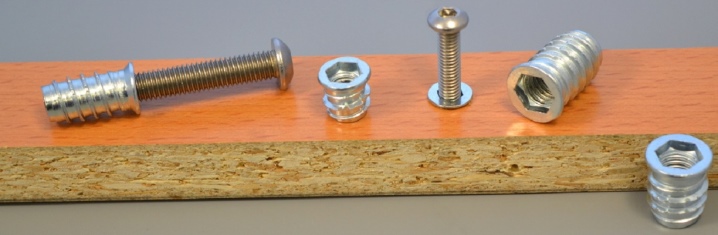

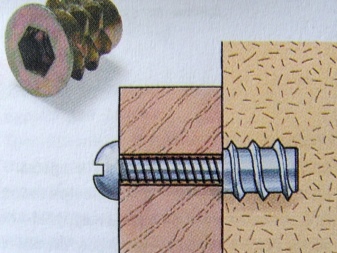

Furniture foot (threaded nut-sleeve, sleeve) is a fastener that allows you to make a socket for a standard metal screw or hairpin in a wooden or plastic surface. It looks like a small cylindrical part with a threaded hole and threads on the outside. Sometimes a retainer is used instead of an external thread. The thread (or retainer) on the outside serves for the most tight fastening in the material, and the inner one for screwing in the screw that attaches the second part.

Thus, the furniture foot works like a nut recessed into the material. This allows you to create various options for screw and eccentric furniture screeds.

The advantages of using a footwear are as follows:

- the counter screw can be screwed in and out an unlimited number of times, which allows you to make furniture collapsible and transformable;

- the connection is more gentle for the material than a self-tapping screw, and this is very important in furniture of soft wood, MDF, chipboard, plywood, plastic; it would be almost impossible to make collapsible structures from these materials without a futorka;

- the aesthetic appearance of the connection - it turns out to be secret and neat, there are no protruding elements that spoil the appearance of the wooden surface;

- allows you to speed up the assembly of furniture, while the fastening is highly reliable: the threaded bushing gives additional rigidity to the connection, absorbs part of the mechanical load; the furniture will not fall apart at the most inopportune moment, will withstand the required weight and will last for many years.

Appointment

The furniture foot is used in those areas of fixation where maximum reliability is required. It allows you to create the following:

- dismountable screw connections, fastening of furniture supports, for example, dismountable tables, chairs with unscrewed legs;

- non-separable screw connections - fixing vertical posts for railings, joining wooden panels, assembling cabinet furniture, installing shelf supports;

- fastening mechanisms for opening furniture doors at different angles - an all-metal canopy on the footboards;

- fastening small functional or decorative parts to the furniture body - hooks, shelves, handles;

- connection of planes at complex angles, long wooden products - fastening parts of handrails at an angle, front panels;

- as a fastening element for eccentric couplers;

- replacement of broken or loose threaded connections.

In all these connections, the foot plays an important role, supporting the entire structure.

Species overview

Furniture frames are presented in two large categories:

- threaded - they have a thread on the outside, due to which they are reliably held in the material;

- without external thread - on the outside, instead of a thread, an annular notch (retainer) is made, often there are additional fixing pins; this option is very convenient for fixing supporting furniture legs.

Fittings of both groups can be equipped with the following additional functional elements:

- spacer mechanism - due to it, the sleeve additionally expands from the inside for a reliable, gap-free connection with the material; a popular option is a foot with a spacer ball, the petals of which wedge when the screw is screwed in;

- a slot for a hex wrench or screwdriver;

- with a flange that provides a large bearing surface, increasing the strength of the connection; in addition, skirts with a skirt are more convenient for installation;

- nylon liner;

- various additional fasteners - clamps, spikes, and so on.

Important! A wide variety of modifications allows you to choose the most suitable option depending on the nature of the work performed, the material of the furniture.

Materials (edit)

Furniture frames are made of metal or plastic. Metal is made of corrosion-resistant steel (carbon steel, steel grade A2, A4), brass, aluminum, non-ferrous metal alloys. For increased resistance to the environment, it can have an anti-corrosion coating - nickel, zinc, chrome, anodized. Metal hardware is used for important fasteners that must constantly withstand increased loads. They have increased wear resistance, but they are not suitable for products made of soft wood and for fastening miniature parts - they are too heavy, there is a high risk that the wooden surface will crack when screwing them in. In these cases, plastic fasteners are ideal.

The plastic case has the following advantages:

- modern plastics make it possible to make very durable and high-quality parts;

- they are not afraid of moisture, resistant to various environmental influences;

- cheaper and easier to manufacture;

- easily cut into surface holes, do not deform, provide a good connection tightness.

Therefore, plastic footwear is widely used in modern furniture fasteners.

Dimensions (edit)

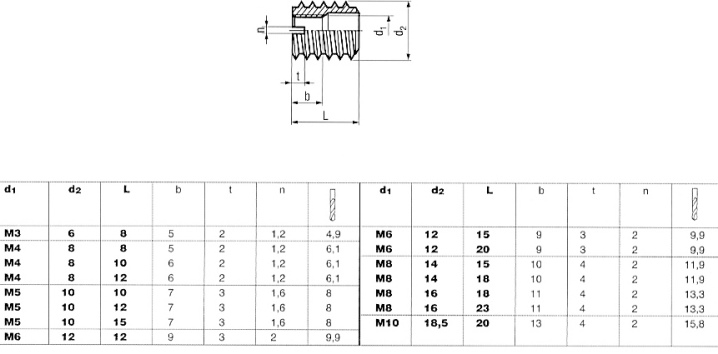

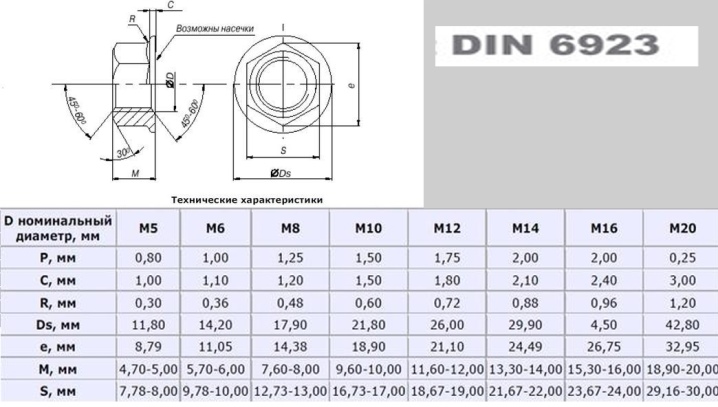

Fittings are presented in different sizes for different tasks. They can be guided by GOST / DIN standards, or they can be atypical, depending on the design decisions of the furniture manufacturer. Atypical ones are usually not sold separately, but are included when ordering ready-made furniture. But basically, manufacturers are guided by the DIN 7965 standard for mortise furniture couplings.

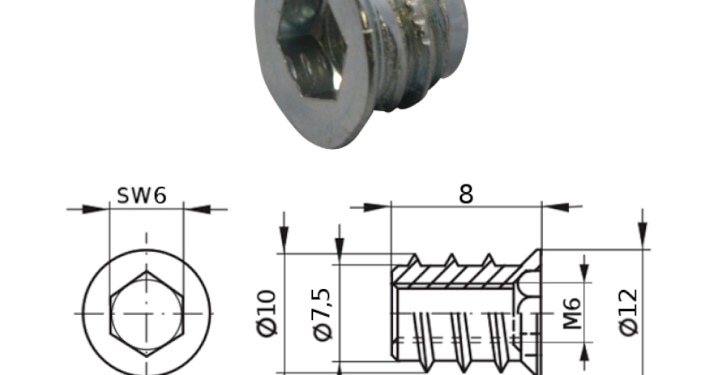

The most common models are those made for a typical metal screw - from M4 to M20.

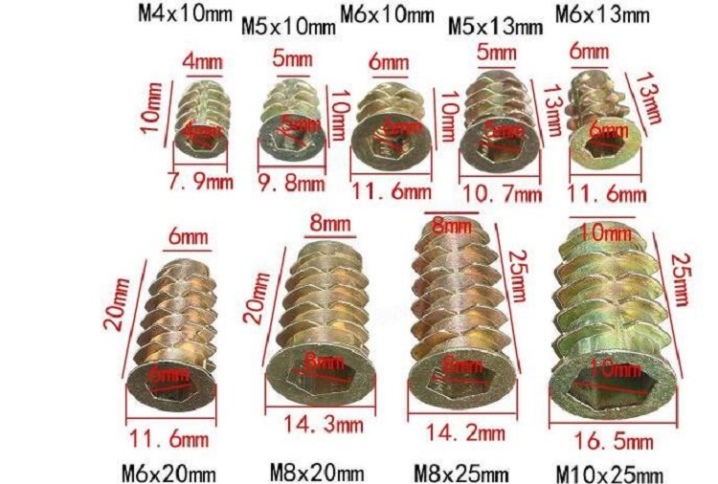

That is, the inner diameter of the foot is selected in the same way as for a conventional nut: a counter screw of the same diameter is attached to it (for an M4 foot - an M4 screw, and so on). The most popular sizes: M4, M5, M6, M8, M10. And also there are couplings for screws, studs, screws.

In order to choose the right shoe, in addition to the diameter of the internal thread, you must also take into account its external diameter and length. The outer diameter is usually 6 to 29 mm. The thread pitch is from 0.5 to 1.5 mm. The outside diameter determines the size of the hole that is drilled in the material. Together with this parameter, the method of fastening must be taken into account - a threaded case, with a notch, with a spacer mechanism, and so on.

Length is how deep the sleeve will go into the material. Usually this parameter is from 8 to 20 mm. You need to choose a footwear in length so that at least a few millimeters remain to the front side (the hole is usually not made through). Also, the sleeve should not protrude and interfere with the installation of other fittings.

In the same time the length must be sufficient for the fastening to be strong and withstand the intended loads. Therefore, one of the most demanded options is a case with an outer diameter-to-length ratio of 10x13 mm for a standard screw. It is considered universal.Although a number of tasks may require miniature fasteners or, conversely, long sleeves for highly loaded fasteners.

Important! You can see the typical ratios of diameters and lengths for DIN sleeves in a special table. And also it indicates the dimensions of the mounting holes for the footboard for various materials.

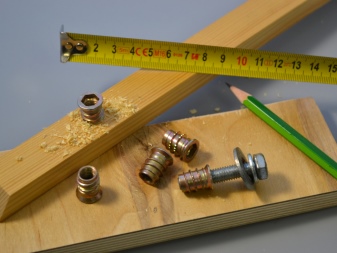

Mounting features

Installing the footwear is a task that you can handle yourself. The main thing is accuracy and attentiveness. The hole for the foot is made using a conventional drill with a drill of a suitable diameter. You can mark the drill with colored duct tape to see how much you need to immerse it in the material. You need to drill a hole, keeping the diameter accurate to the millimeter. If the hole is larger, the sleeve will not be able to hold, if it is too small, it will be impossible to screw it in. Therefore, you need to accurately measure everything and choose the right tool.

It is recommended that you use a drill designed for the wood or material you are working with. So there is less risk of damaging the material. The drill bit for metal is too tough, it is better not to use it for working with soft wood or DPS. The size of the hole is usually made equal to the outer diameter of the foot or 1–2 millimeters smaller (when screwing in, the thread of the foot cuts the material additionally, the adhesion is tight, without gaps). How many millimeters to throw in each case depends on the material in which the sleeve is fixed and on the method of attachment (thread, notch, additional spikes).

Important! Each version of the foot may have its own optimal requirements for the size of the hole. They must be clarified in the accompanying documentation before starting work.

When the hole is ready, you need to insert the foot into it. Threaded furniture couplings are installed by screwing in with a screwdriver or a hex key, if there is a slot, a screwdriver can be used. When working with hard types of wood, wax or a special lubricant is used to facilitate screwing. The protruding excess of the substance also allows you to control the tightening force. Fittings without thread are hammered in with a hammer.

For an overview of furniture fittings, see below.

The comment was sent successfully.