All about locking screws

It is very important for users, repairers and various specialists to know everything about locking screws... The locking of screws for door handles has its own peculiarities; the requirements of GOST must also be taken into account. It is imperative to study the features of the M8 and M10 screws, fasteners of other sizes.

Peculiarities

Before understanding the features of the locking screw, you must pay attention to the definition in GOST. For such products, standard 27017-86... According to him a screw is a fastening structure that allows you to connect or fix different objects. The product is a rod with an external thread on one end and with a torque transmitting part on the other end. It is worth noting that the definition of a bolt is very similar, and there is no clear boundary between them.

All such constructions have marking of two digits separated by a multiplication sign. Before it, write the section below the head, and after it - the distance from the tip to the largest transverse section of the head. Both quantities are measured in millimeters. Fasteners for metal have a stable, uniform cross-section of the rod along the entire length. Products are either screwed into threaded holes, or passed into through channels made in the packages to be joined.

Do not think that locking screws are needed only in some advanced engineering industries. It is equally important to use them for a doorknob. Set screw in accordance with DIN 914 standards helps in high vibration environments... Sophisticated geometry increases the strength and stability of the joints created.

For this purpose, it is even provided for the tip to fall into a precisely prepared mating hole.

What are they?

The choice of the appropriate fastener option depends on the following factors:

- intended purpose;

- external parameters;

- the required level of reliability;

- number and dimensions of mounting screws.

The main purposes of the application are:

- assembly of various equipment;

- replacement of items that have become unusable;

- increasing the aesthetics of the appearance of the joints.

External factors can be considered climatic parameters, features of dynamic and static influences. Along with reliability, one has to consider accessibility for installation (dismantling), quality of protection against deformation of fasteners... For particularly difficult climatic conditions, use galvanized fasteners.

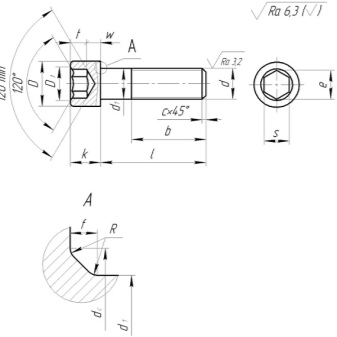

Hexagon (including internal) is used when a particularly strong fastening is required. Execution of hexagons can be made according to DIN 912 or GOST 11738Both standards also make it easier to use in hard-to-reach places and protect the structure from dynamic loading.

Grub screw M6 has a cross section of 0.6 cm.If we talk about the modification M6x10, then its length reaches 1 cm. Tapered screw M8 can have a length of 0.8 cm. Typically, alloy 45H HEX 4.0 is used in the manufacture of such fasteners.

It is a high quality and durable oxidized steel.

Fasteners with a length of 0.6 cm can be made of the same alloy.There are also options uncoated or with a zinc layer.

M8 screws are also available in lengths:

- 12;

- 14;

- 16;

- 20;

- 25;

- 30;

- 40;

- 50 mm.

As for the M10 screws, their length can be:

- 10;

- 12;

- 20;

- 25;

- 30;

- 35;

- 40 mm.

Usage Tips

The set screws are devoid of the head typical of conventional mounting counterparts. A cross-shaped or flat slot is applied directly to the end of the product. If you need to achieve maximum strength, you must use modifications with an internal hexagon in the slot.In practice, it has been proven that this performance increases the scrolling power. The risk of premature failure will be close to zero.

It should be borne in mind that the presence of an internal hexagon forces the use of special assembly (so-called imbus) keys. Other tools are not suitable for this job. You can screw the screw completely into the part. The use of grooves and protrusions allows for a tighter hold. First of all, a screw is screwed into the thread, passing the product to the full depth, and then it is tightened on the outside.

Locking screws in mechanical engineering can be used to mount pulleys or gears on shafts. A screw is tightened inside the hub. This product is inserted end-to-end into the threaded shaft passage. Such a connection perfectly fulfills the frictional force. Along with this, elastic deformation between the fastener and the part plays an important role in tight fixation.

Set screws can be used in a wide variety of applications... They are even used in precision instrumentation. But, of course, it is necessary to carefully study the features of a particular situation and permissible conditions. Using screws with drilled end and hexagon inside it is required to check their compliance with GOST 28964, DIN 916. The normative category of strength is 12.9, before installing such screws, pre-drill and cut a thread.

You can watch a video overview of the set retaining screws in the video below.

The comment was sent successfully.