How to choose and use molly dowels?

In order to properly and effectively fasten many sheet wood materials, it is necessary to figure out how to correctly select and use molly dowels. This means that you will have to study the features of the anchor guns and take into account the appropriate dimensions of the drywall anchors. An equally important point is how to use metal and other dowels correctly.

Description

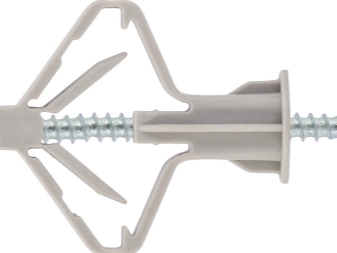

Molly dowel is a type of fastener for drywall and similar materials. By default, such a product is formed entirely of metal. There are almost no structural differences from the "butterfly" fastener. However, the elimination of plastic elements increases the load-bearing capacity. True, this is achieved only when the design itself is more expensive.

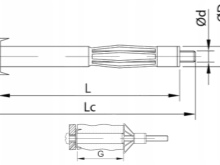

The main components are screw and sleeve blocks. The screw is either included in the kit by default, or is customized according to your preference. A metal collet is an empty bushing inside.

Its middle is equipped with longitudinal slots. It is this component that is responsible for the strut after twisting.

Since the collet can contain grooves inside, this complicates the selection of a suitable screw. An alternative option is to complete the screw from the original kit with a support washer. This washer will have a pair of serrated tipped ridges. It is attached to the surface, which will prevent the collet from spinning uncontrollably during installation. Finally, there are modifications of screws with countersunk heads or with conventional tips in the form of a semicircle.

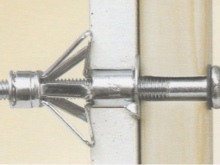

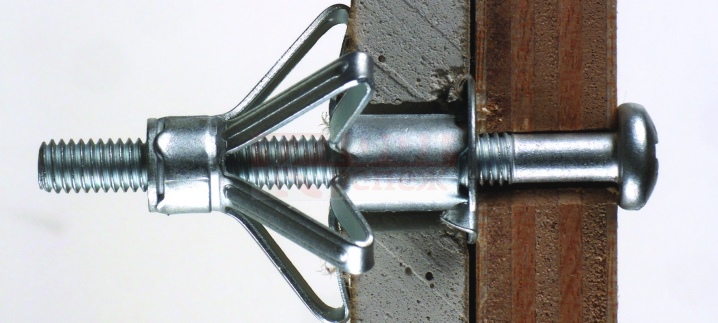

The principle of operation is quite simple: the molly dowel is inserted into the required hole when it is folded. Next, tighten the required screw inward. When this happens, the spacer is compressed. In this case, a support is formed in the form of many petals, reminiscent of a "tent" or an umbrella. It will press firmly against the wrong side of the material being cut.

It is necessary to fasten such an anchor a little differently than in the case of a simple "butterfly". The screw may not be screwed in, but, on the contrary, pulled out. To work with it, you need dowel pliers or assembly pliers. But a typical locksmith tool from a home workshop will not help. Molly dowels can be dismantled and reused (this is not possible with a simple "butterfly"); manufacturers even specifically emphasize that dismantling will not affect the operating parameters.

The main material for molly dowels is steel (galvanized or with additives that reduce the risk of rusting). The second option is noticeably more expensive and is acceptable only for the most critical areas.

It should be noted that the described type of dowels will require a fairly significant free space for installation. Manipulating pliers and pliers in a confined space is extremely difficult, because this tool itself has a certain length.

For your information: for double drywall, only special designs can be used. Such fasteners include a tip in the form of a drill. Only such an end part can be safely and reliably screwed into a thick sheet. Alternatively, you can use "self-aligning" dowels, strips and other types of fasteners. But this is a separate topic that requires special analysis; but for hollow structures, a typical Molly dowel is perfect.

Species overview

By material

As already mentioned, this type of fastener is extremely rarely plastic, because it is designed to withstand the load as efficiently as possible.But the metallic element can vary significantly. Only 2 main types are known - there is a pronounced difference between them. Galvanized steel structures are mainly electroplated. Where there is an increased risk of corrosive processes, only stainless alloys are suitable.

By design features

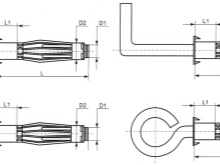

Molly dowels M10 and other sizes can have a rather different technical design. The differences, however, relate, rather, not to the fasteners in general, but to the main screw. Countersunk head models are quite common. They have a flattened cap that is recessed in the wall or in the material being processed. This design is very reliable, but it is extremely difficult to dismantle it.

When trying to pull out the flush-mounted dowel, you will definitely have to damage the material. In the case of a semicircular head, the fastener will be open, and it is much easier to pull it out.

However, this comes with significant aesthetic costs. Some models are available with a hook screw. This solution is optimal for a chandelier or other suspended luminaire.

It manifests itself especially well when installing lighting fixtures on plasterboard ceilings.

Sometimes you can find designs with a hook in the shape of the letter G. They are no longer used for ceiling, but rather for wall lamps. The help of such a dowel is invaluable when installing household appliances (TVs, microwave ovens) on the wall from the gypsum board. Of course, in this way you can also fix various kinds of furniture (wardrobes, bedside tables, shelves), pictures, pots. Finally, to work with non-standard structures and communications (such as hanging chairs and swings), molly dowels with a special ring are used.

Dimensions (edit)

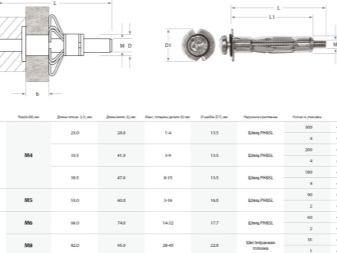

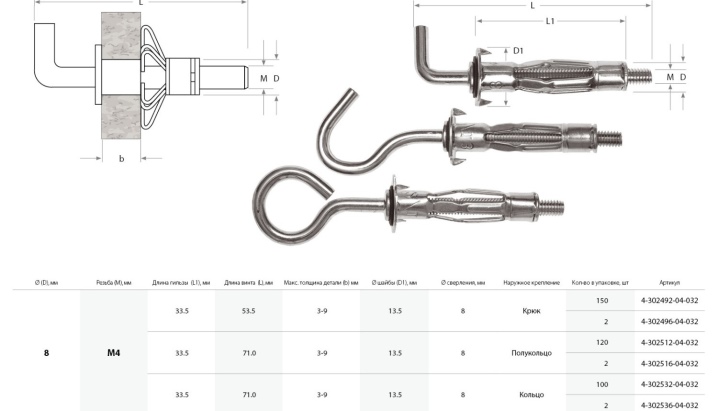

In Russia, there are no state standards for this type of fastener, and therefore domestic suppliers use the technical conditions developed by them. Products from Finland and Germany are manufactured in accordance with the current EU standards. The most commonly used sections are 0.4, 0.5, 0.6 and 0.8 cm.

The length of the structure varies from 2.1 to 8 cm, however, each manufacturer has the right to choose the appropriate parameters himself - this is not regulated in any way all over the world.

Molly dowels, compared to other similar fasteners, They have a very high bearing capacity, but you must try to ensure the workload is not higher than 30% of the maximum, otherwise the stability of the connection will be in question.

Dimensions, cm | Permissible load when mounted on chipboard 1 cm thick, Newton | Maximum load when screwing into drywall (per sheet 0.95 cm), Newton | Weight 100 pieces (in grams) |

0.4x2.1 | Not standardized | 150 | 600 |

0.4x3.2 | 250 | 150 | 718 |

0.4x3.8 | 250 | 150 | 850 |

0.4x4.6 | 250 | 150 | 940 |

0.4x5.4 | 250 | 150 | 950 |

0.4x5.9 | 250 | 150 | 1090 |

0.5x3.7 | 250 | 150 | 1180 |

0.5x5.2 | 250 | 150 | 1550 |

0.5x6.5 | Not standardized | Not standardized | 1970 |

0.5x8 | Not standardized | Not standardized | 2360 |

0.6x3.7 | 250 | 150 | 1560 |

0.6x5.2 | 250 | Not standardized | 2080 |

0.6x6.5 | Not standardized | Not standardized | 2640 |

0.6x8 | 250 | Not standardized | 3140 |

Selection nuances

Molly dowels are produced by a variety of companies specializing in the production of fasteners. That's why choosing a suitable product, focusing only on the "name" of the company, is unlikely to work, after all, the assortment now also includes products from companies that are little known to Russian buyers. Unconditional leadership in the world was won by molly dowels under the Fischer brand. The German company produces all kinds of fasteners possible at the modern technical level; the difference in price between them is quite noticeable.

Another German company - EKT - produces excellent galvanized steel dowels. On average, one piece requires from 35 to 58 rubles.

Lovers of Finnish products should pay attention to branded products Sormat. This company supplies molly dowels for sheet materials. For 50 pieces in the original packaging, you will have to pay at least 650 rubles.

Russian counterparts are much more affordable. Depending on the specific brand and on the characteristics of the product, it will be possible to buy 100 dowels for 190-500 rubles.The price of installation work is practically independent of the use of fasteners. Even a special assembly tool is readily available. No special skills are required either; however, the fees for Molly are hefty when the workload is large.

Quite good results in practice are demonstrated by the products of the Liechtenstein company Hilti. It has passed the most severe tests and has proven itself from the best side many times. As for the already mentioned products from Sormat, as well as from German suppliers Tox and Kew, they are generally of high quality, but they have not been certified for particularly difficult conditions.

The most favorable prices are assigned to the products of little-known Russian and East Asian firms. However, relying on such fasteners is somewhat unwise.

And one more consideration - this time in relation to the material from which the fasteners are made:

in the absence of special requirements, it is necessary to take modifications with zinc protection;

for bathrooms, kitchens, unheated rooms, alloyed stainless alloys are better suited;

only the lightest objects can be hung on the plastic supports - regardless of the microclimate.

How to use it correctly?

When using molly dowels, a special assembly gun is required. And this is not a mistake - it's just that the already mentioned ticks are called in an alternative way. Important: if they are not there, a screwdriver or even an ordinary screwdriver can be a temporary replacement. The fee for such a device is approximately 200 rubles.

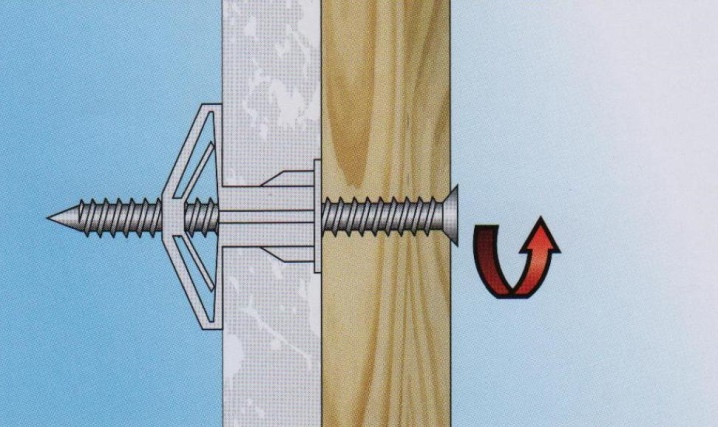

The dimensions of the dowel used must exactly match the thickness of the base. You can install the dowel like this:

drill a hole along the cross-section of the sleeve;

to hammer it with the expectation of the entry of the teeth into the material being processed;

screw on the screw block.

But if all this can be done with a simple tool, then in order to attach Molly further, specialized pliers are required. They have a special slot on the working area. It goes from the head of the screw to the washer. It is imperative to check whether the device is correctly installed. Manipulating it is no different from working with any other ticks.

The applied force, squeezing the dowel, makes it open and fix. It is worth considering that problems can arise when there is insufficient clearance from the screw cap to the washer.

This will prevent the top from catching against the washer. It is not difficult to eliminate the difficulty - you just need to slightly tighten the screw by hand. It is advisable to perform such a manipulation before inserting the dowel into the drywall - then there will be no doubt that the screw is quite firmly held in place.

It is also important to follow other technical guidelines. Molly dowels are designed for a load of no more than 35-50 kg. It is even better to leave some reserve, because sooner or later it will be necessary to compensate for additional impacts. Manufacturers in the marking indicate the total length of the product, the section of the metric cut and the greatest thickness of the base. It is also recommended to ensure that the distance between the head and the spacing zone matches the thickness of the material; when such a condition is not met, the fasteners do not hold well or breaks the material.

Attach something carefully. It is important to remember the difference between hollow and solid materials. In the presence of a void, the hardware holds up much worse. Problems can also arise when fastening to thin sheets. Important: when installing suspended objects, the screw only needs to be screwed in once.

For dowels for attaching to thin-walled materials, see below.

The comment was sent successfully.