All about dowels for gas silicate blocks

Gas silicate blocks are a popular and beloved building material that allows you to quickly build perfectly flat walls, partitions and window lintels. The porous structure of the blocks gives them light weight, provides good sound absorption and good thermal insulation, but creates problems with fasteners. The solution will be special dowels, the choice of which in modern stores is quite wide.

Characteristic

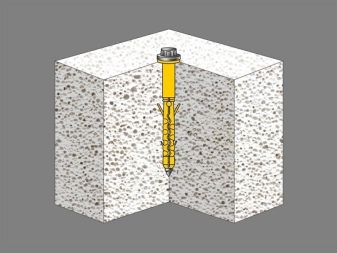

Fasteners for gas silicate blocks have some structural differences from products for solid concrete, brick and wood. This dowel is a spacer part of the fastening set, which is securely fixed in the wall material by expanding the sleeve (collet) when screwing in a screw, self-tapping screw, or held by a thread.

The surface of the gas silicate dowel has pronounced irregularities and sharp edges, is distinguished by large spiral-shaped blades or very large helical threads.

It is the high thread, due to which the total diameter of the dowel noticeably exceeds the diameter of the drilled hole, "clings" to the block structure and allows the load pressure to be evenly distributed in the porous base.

Views

Today there are several types of plugs for gas silicate blocks on the market. Leading manufacturers of this product: "Crepe-Comp", Tech-Krep, Sormat, Fisher, HPD and other firms in Russia, Europe, China. Dowels are made of plastic and metal. Plastic products are resistant to aggressive environments and can be used in rooms with high humidity. A pair of such dowels will be universal screws, wood screws, self-tapping screws.

Types of plastic dowels include several items.

- Polyethylene - cheap, but have the lowest tensile strength, pull-out strength, abrasion and are suitable for temperatures ranging from -5 to + 30 ° C.

- Polypropylene - also have an affordable price, are not subject to corrosion, are perfect for indoor work. They can be used at temperatures from -20 to + 50 ° C.

- Nylon - This material works perfectly in a wide temperature range from -40 to + 80 ° C and has a higher tensile strength and abrasion resistance. Its “aging effect” is practically minimal: its service life is up to 50 years. They will hold large furniture and household appliances, they can be used in facade work: fix drain pipes, street lighting elements, use for the installation of windows and doors, air conditioning and ventilation systems (for example, German wall plugs for EJOT and Fisher GB facades).

The nylon options are more expensive than the less sturdy and durable plastic options.

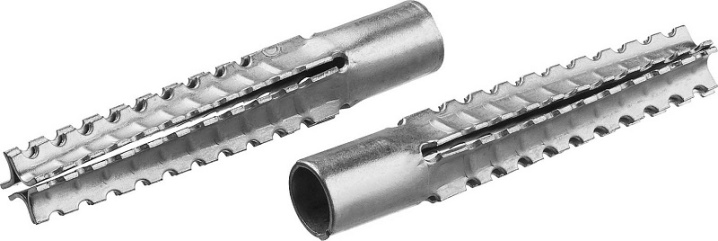

There are several types of metal dowels.

- Steel galvanized - durable and fire resistant. Durability is provided by a special coating (for example, yellow zinc for MUD 8x60 mm), a 4-segment spacer with teeth “sits” securely in the gas silicate block, it is not necessary to drill a hole - the dowel is clogged. This design is often used when installing clamps for gas and water pipes and because of the raised toothed surface, it is colloquially called "crocodile" or "herringbone".

- Zinc and aluminum alloy - as an example, we can cite the KVTM screw dowel from the Sormat brand (Finland) with internal and external threads.

Two more species stand apart.

- Dowel nail - a galvanized steel nail screw (with a cross on the head for dismantling) is driven into a polypropylene or nylon long cylinder. The dowel can have a hidden or mushroom-shaped rim. The set is selected so that the nail point comes out of the sleeve during installation - this increases the strength of the fastener.

- Frame - such a dowel for the installation of window and door frames can be made of both plastic and metal. Its long and smooth, non-expandable part occupies the main part of the product in order to freely pass through the frame and create a spacer only in the block itself.

Features of choice

A lot of cells in the "body" of gas silicate concrete are formed from the release of gas during the reaction of aluminum powder with a lime-silicon mixture. Depending on the density, the blocks are marked and have different applications - from insulation material to structural for the construction of partitions and load-bearing walls of low-rise buildings. It is advisable to know the block strength parameter in order to choose the right fastener. But even the densest and most durable gas silicate of the d700 brand remains cellular and requires not standard, but special solutions.

It is still possible to fix light decor items (photo frames, calendars, small posters without glass) on a wall made of porous blocks using the usual universal set "dowel-screw". And sometimes it is enough just to screw a large-threaded self-tapping screw for wood into the block.

Installation of heavier decorations, as well as furniture, water heaters, air conditioners, sinks should be done only with high-quality specialized products for aerated concrete.

Experts recommend:

- for paintings and not too massive shelves, switches, to install skirting boards, it is enough to buy a set of polypropylene dowels of small diameters;

- hang sconces or mirrors nylon dowels with a diameter of no more than 12 mm will help;

- installation of furniture structures, including heavy ones, should be performed with nylon dowels (8x55 mm; 14x80 mm);

- metal recommended for the highest loads and for laying pipes;

- frame fit for the installation of door frames and double-glazed windows;

- profile battens for facade cladding must be attached to universal front wall plugs (nylon, stainless steel).

The selection takes into account such characteristics as:

- the value of the ultimate load on the fasteners (indicated on the package);

- overall dimensions - you need to choose a dowel of large diameter and length for a significant load;

- material - products that are not subject to corrosion are used for external walls and unheated rooms.

To select the correct gas silicate fasteners, you need to study the product label, consult the seller in the hardware department, or find a detailed description of the products of a particular brand on the Internet. For example, for a nylon screw dowel with a coarse thread 6x50 mm from Europartner (Russia), the approximate supported weight is indicated - 30 kg, and for a model made of 10x60 mm nylon with blades - 120 kg.

Installation rules

The main installation methods are twisting and hammering into a prepared hole.

- With a hammerless drill (you cannot use a punch, it can crush the material) a hole is drilled in the gas silicate block. For plastic dowels, it is recommended to use a drill with a diameter of 1 mm less, for metal dowels - 2 mm.

- The cavity is blown out of dust.

- The fasteners are neatly, without distortions, screwed in with the installation tool (installation of KBT dowels is carried out using a hexagon, with other models a screwdriver works) or hammered with a hammer (metal dowels), a rubber mallet.

- The final stage is tightening a self-tapping screw or mounting screw. It is better to do this operation without an electric tool, manually, or start the screwdriver at low speed.

Special dowels for gas silicate blocks appeared not so long ago, as, indeed, this attractive building material itself. Most likely, in the future, various installation designs will be developed and existing ones improved.

There is no need to neglect specialized fasteners, because they provide reliability and safety.

For information on how to choose the right dowels for gas silicate blocks, see the next video.

The comment was sent successfully.